Technological method for processing natural material sandstone processing system waste water

A processing system and wastewater treatment technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of not fully adapting to natural material system wastewater, and achieve the effects of improving wastewater treatment efficiency, reducing costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

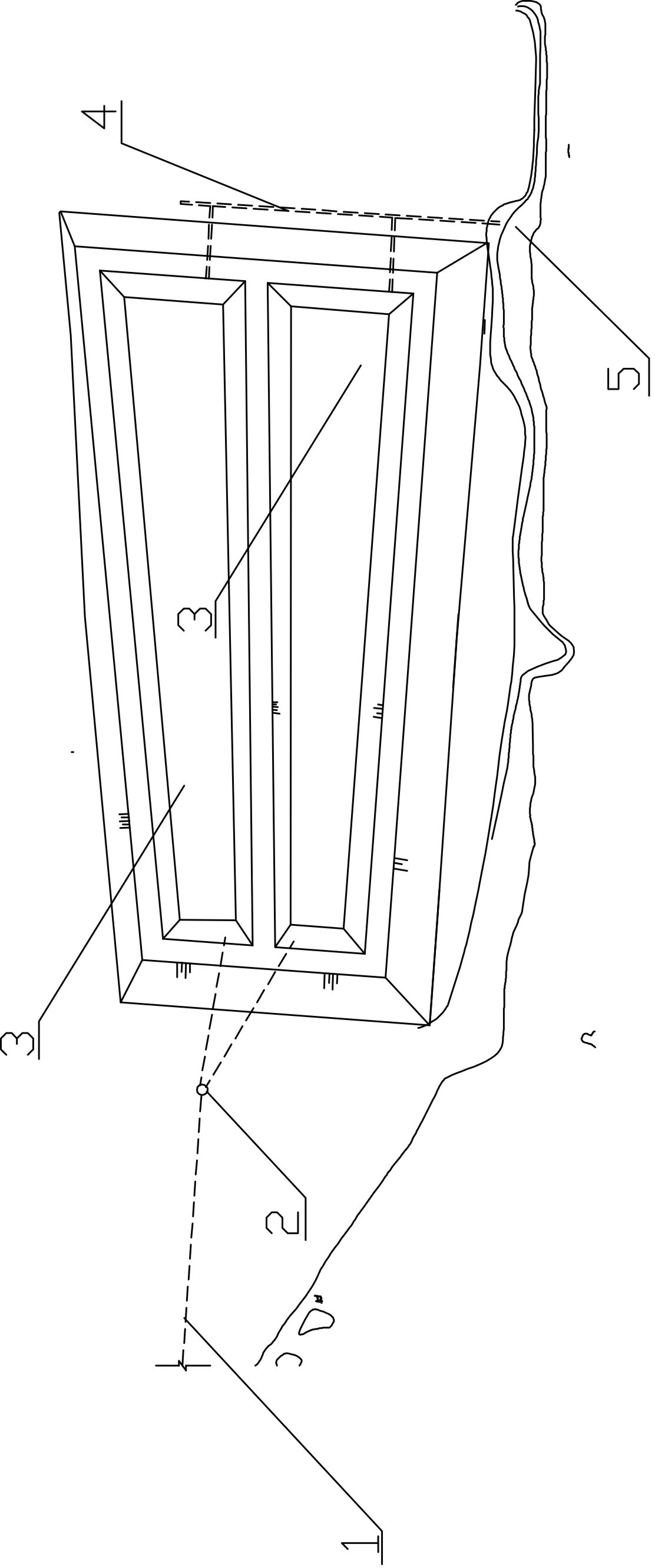

[0021] Such as figure 1 Shown, a kind of processing method of natural material sandstone processing system waste water treatment, this method comprises the following steps:

[0022] 1) Collect the waste water from the natural material sand processing system and transport it to the water collection and distribution well 2 through the channel pipe 1, and then distribute it to the waste water sedimentation tank 3 from the water collection and distribution well 2 for natural precipitation;

[0023] 2) The suspended matter in the naturally precipitated wastewater in step 1) settles to the bottom of the wastewater sedimentation tank 3, and the supernatant that meets the discharge standard is discharged into the river water 5 through the drain 4 connected to the wastewater sedimentation tank 3.

[0024] The waste water sedimentation tank 3 is the waste slag storage site of the natural sand and gravel processing system.

[0025] The wastewater sedimentation tank 3 is a masonry struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com