a filling machine

A filling machine and frame technology, applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as complex structure of transmission components, influence on drug safety, and pollution of drug liquid, so as to simplify the mechanical structure and reduce sanitary dead ends , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

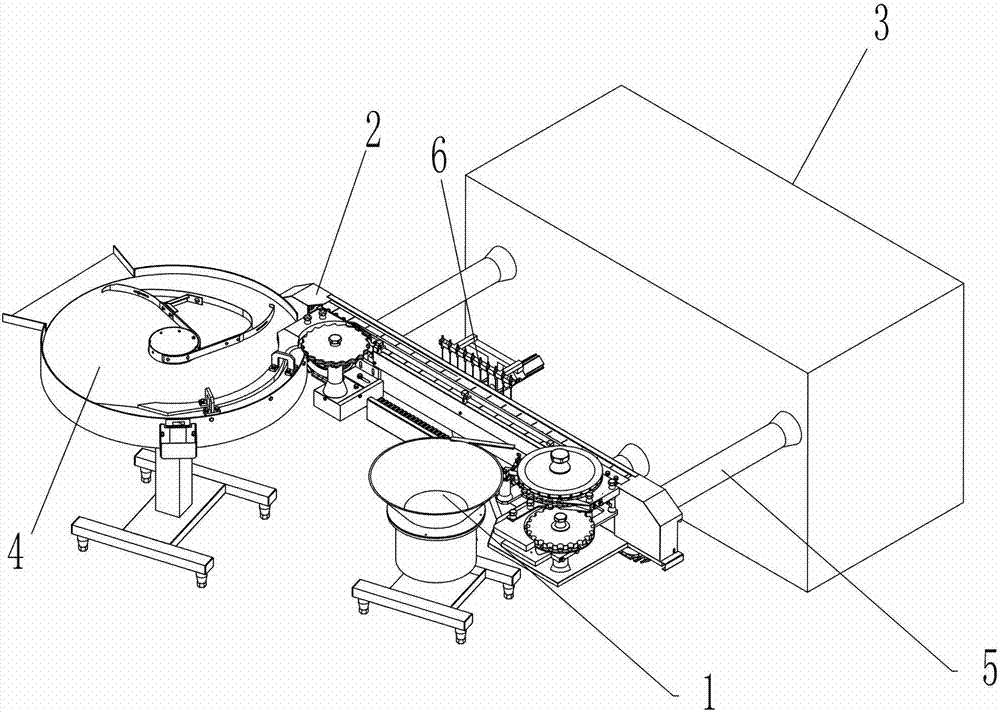

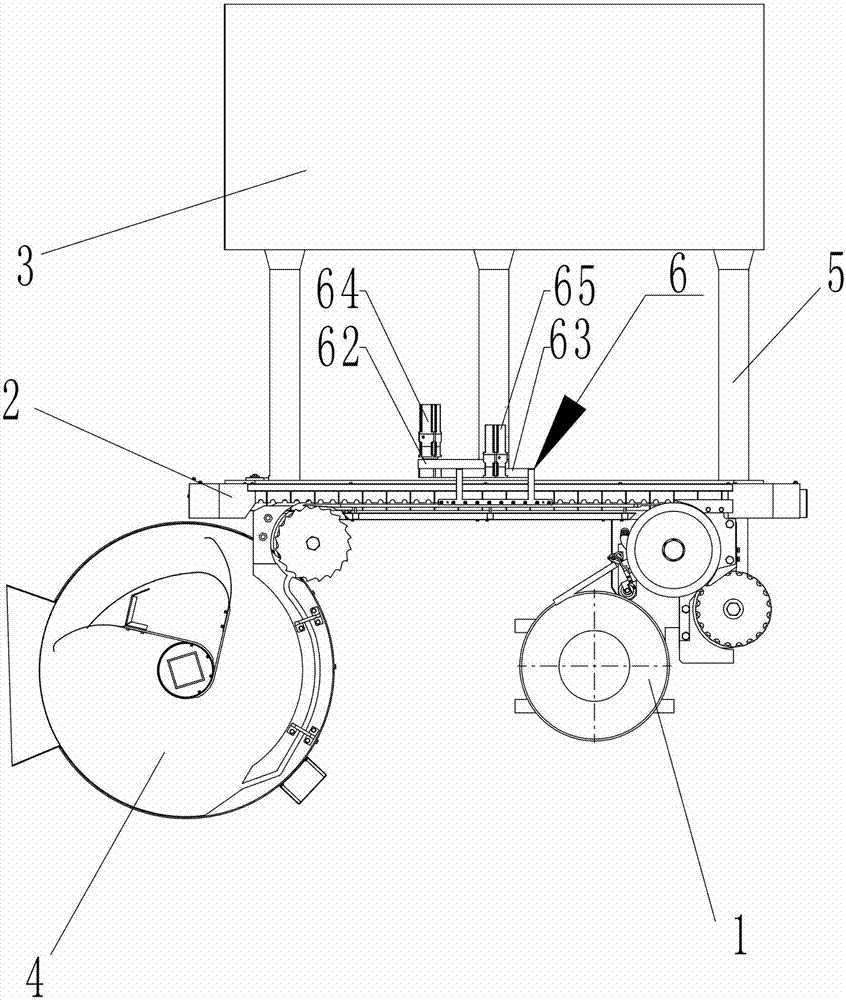

[0026] Such as figure 2 and image 3 As shown, the filling machine of the present invention includes a bottle inlet assembly 1, a bottle delivery assembly 2, a frame assembly 3, a filling assembly 6 and a bottle outlet assembly 4, and a bottle inlet assembly 1, a bottle outlet assembly 4 and a frame assembly 3 They are respectively installed on the ground through their respective supporting components. The bottle inlet assembly 1 is used to transfer the glass bottles of the previous process to the bottle delivery assembly 2. The filling assembly 6 is used to complete the filling operation of the glass bottles. The bottle output assembly 4 It is used to convey the filled glass bottles to the next process. In this embodiment, the bottle conveying assembly 2 is mainly composed of a conveyor belt, which is used to convey the glass bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com