Overflow pipeline type high-speed dispersion machine

A high-speed disperser and overflow pipe technology, which is applied to mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve problems such as excessive solid particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

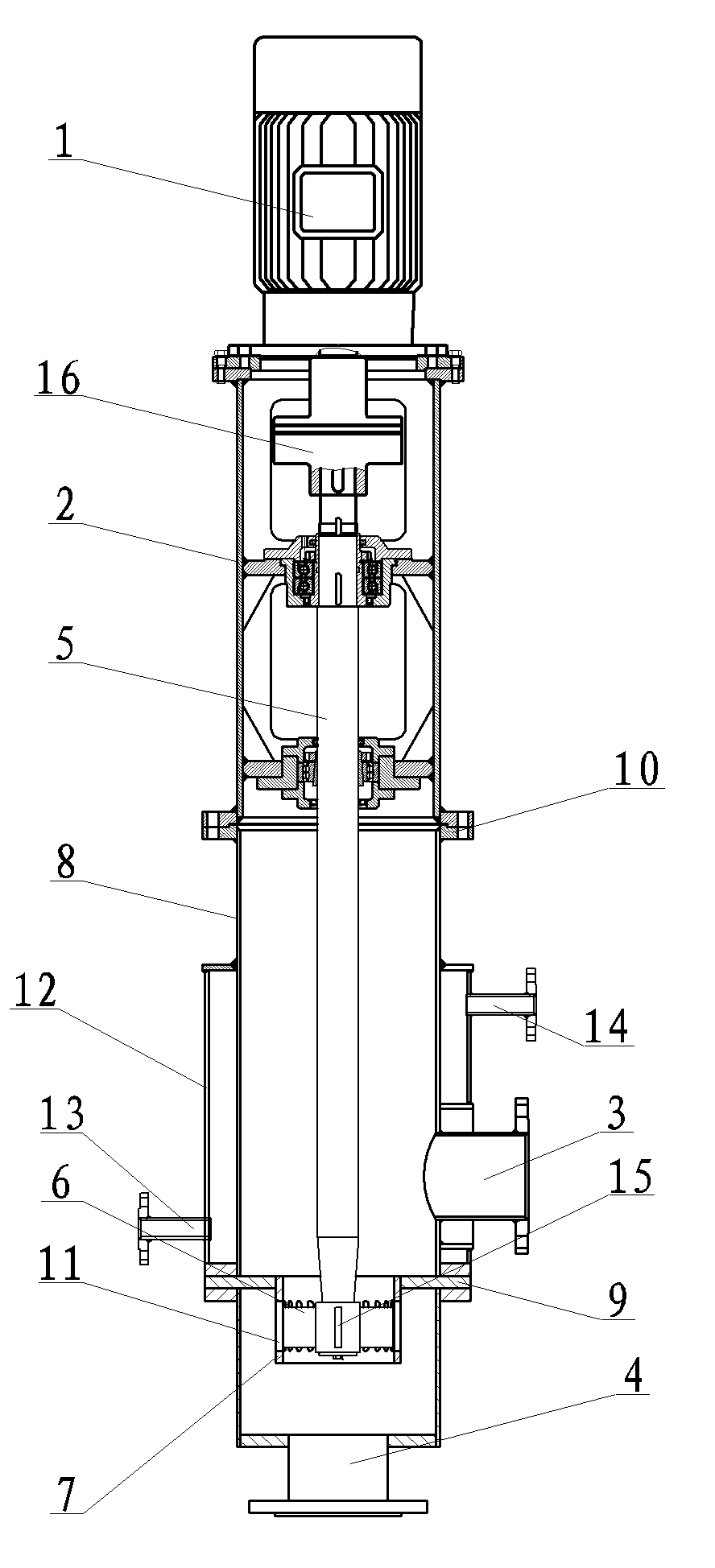

[0014] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0015] As shown in the figure, the overflow pipe type high-speed disperser includes a motor 1, a frame 2, a feed port 3 and a discharge port 4, the motor 1 is arranged on the upper end of the frame 2, and the frame 2 A stirring shaft 5 connected to the motor 1 is provided inside, the stirring shaft 5 extends out of the machine base 2 and a rotor 6 is provided at its end, and a stator 7 matched with it is provided on the periphery of the rotor 6, and the rotor 6 is 6 is provided with vanes 15 on the periphery, and the side of the stator 7 is provided with dispersion holes 11 corresponding to the rotor 6. The dispersion holes 11 cooperate with the vanes 15 to form the rotation of the rotor 6 to drive the blades 15 so that the material is discharged from the dispersion holes 11. And realize the shearing and dispersing of material, described feed inlet 3 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com