Adjustable filter head of cast-in-place filter plate

A technology of cast-in-place filter plate and filter head, which is applied in the field of water treatment, and can solve problems such as poor fastening of filter rods, adverse effects of long-term operation of filter tanks, and increasing the horizontal error range of cast-in-place reinforced concrete filter plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

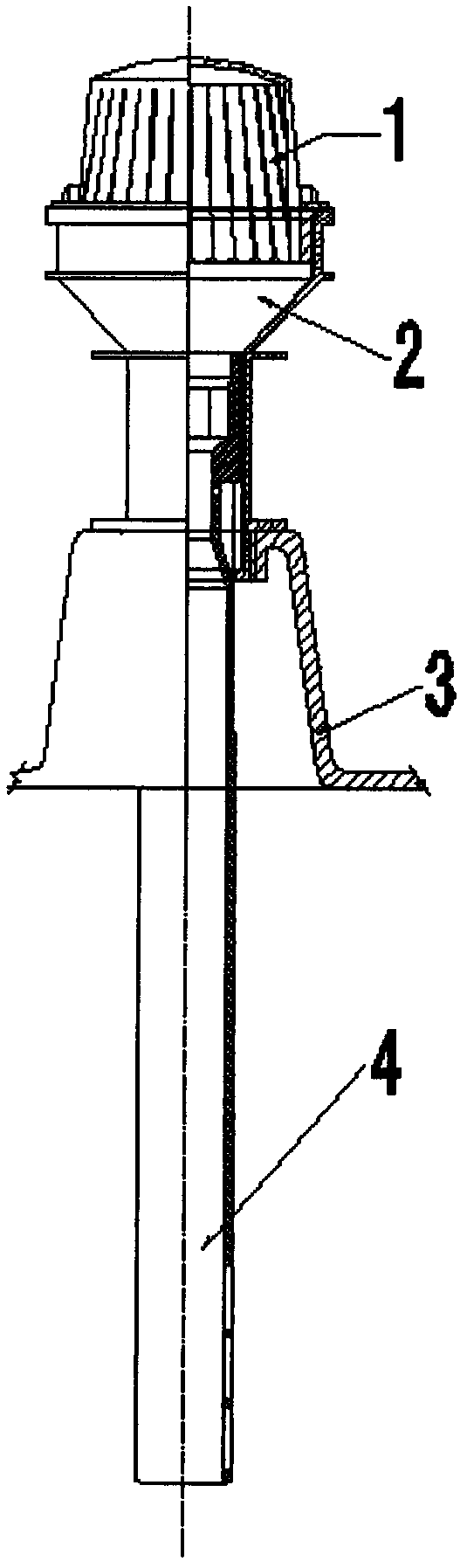

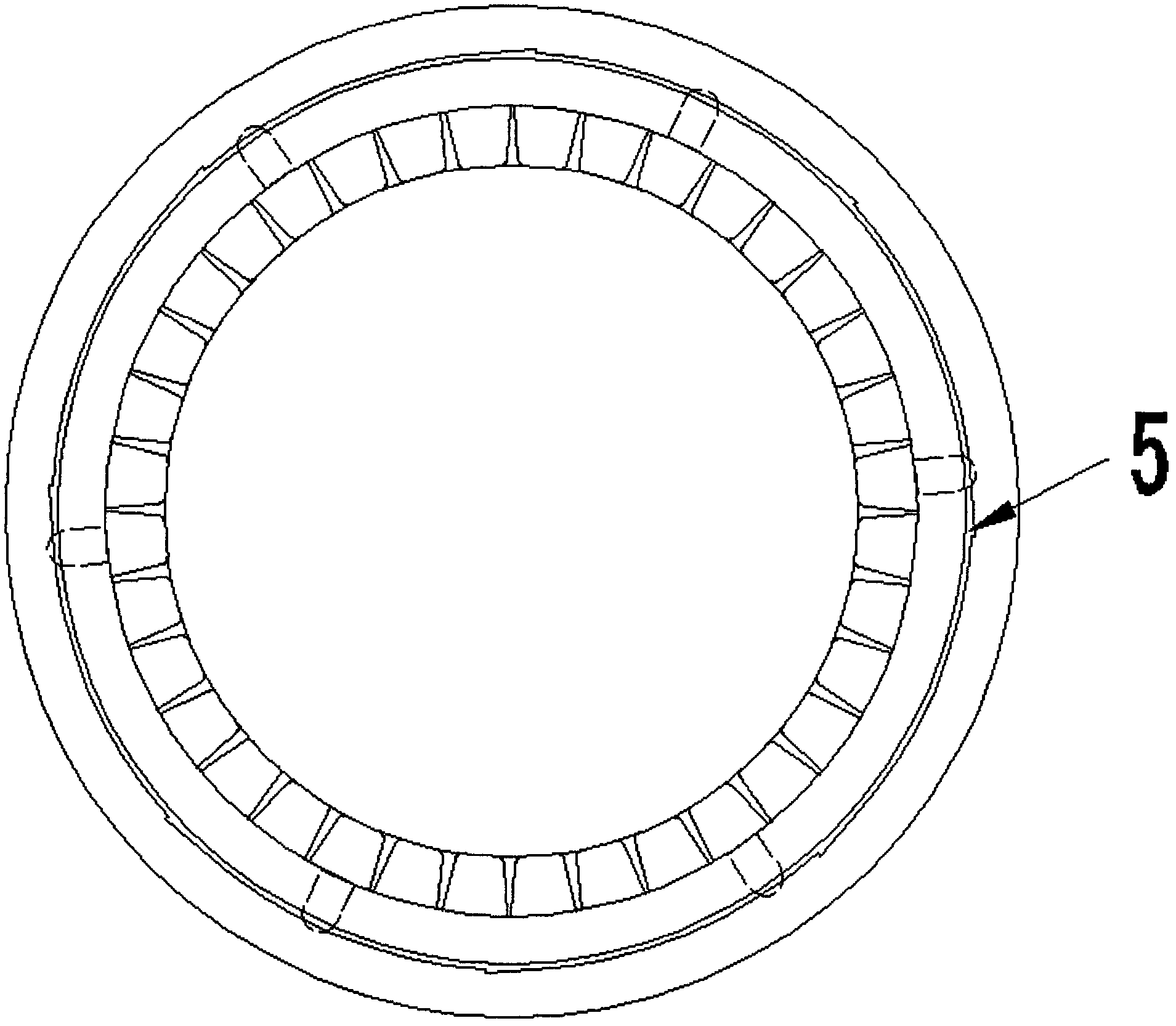

[0030] Example: such as Figure 1-9 As shown, a cast-in-place filter plate adjustable filter head includes a filter cap, a filter seat, a filter rod, and a template; the filter cap is connected to the filter seat, and is also provided with matching vertical check teeth for fixing; The filter seat is threadedly connected with the filter rod and the template, the filter rod and the template are provided with matching clips; the filter seat may be provided with a matching clip with the clip of the filter rod; the filter Matching non-return clamping teeth are also provided on the seat and the template.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com