Screw detection mechanism and detection method and automatic production line

A detection mechanism and screw technology, which is applied in the direction of measuring devices, instruments, metal processing, etc., can solve the problem of not being able to accurately detect whether the screw is screwed in place, so as to prevent the reduction of work efficiency, the increase of maintenance costs, and the effect of avoiding loose connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

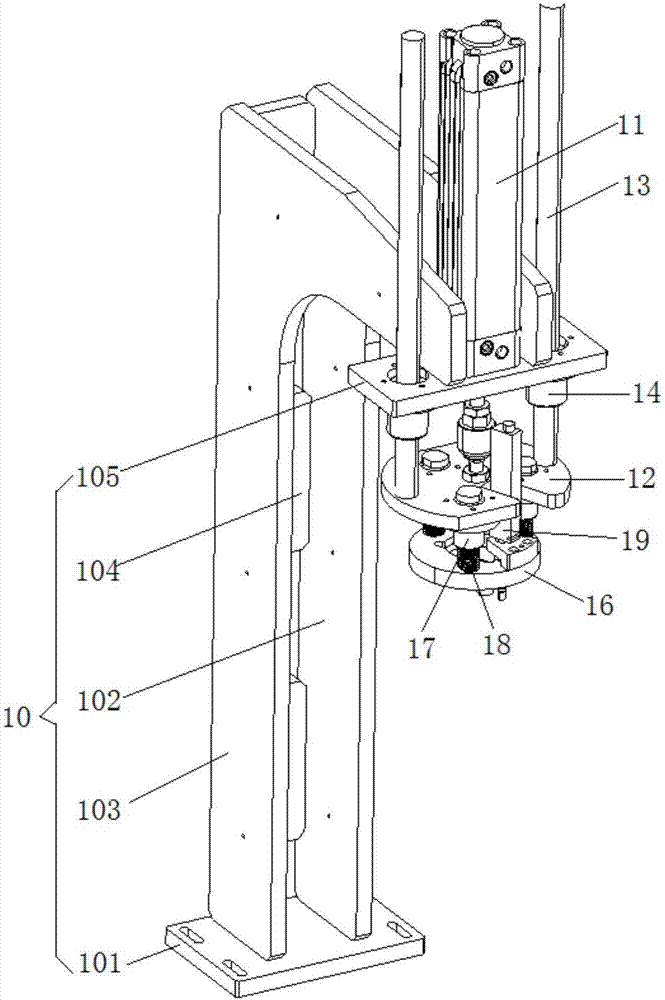

[0038] Such as figure 1 and figure 2 As shown, the present embodiment provides a screw detection mechanism for detecting whether the screw is screwed in place. The screw detection mechanism includes a frame 10, a cylinder 11, a connection plate 12, a detection plate 16, a connection column 15, a detection part 161 and a displacement sensor 19.

[0039] The frame 10 comprises a base plate 101, a first support plate 102, a second support plate 103, a reinforcing plate 104 and a cylinder fixing plate 105, wherein the first support plate 102 and the second support plate 103 are L-shaped, and the first support plate 102 is arranged in parallel with the second support plate 103 at intervals, and the end of the vertical portion of the first support plate 102 away from the horizontal portion and the end of the vertical portion of the second support plate 103 away from the horizontal portion are all fixedly connected to the bottom plate 101; The plate 104 is connected between the ve...

Embodiment 2

[0049] Such as Figure 3 to Figure 5 As shown, the screw detection mechanism provided in this embodiment is basically the same as that in Embodiment 1, and for the sake of brevity, only the differences from Embodiment 1 will be described. In this embodiment, the screw detection mechanism can detect a plurality of screws at a time, that is, the detection part 161 has a plurality of detection protrusions 1611 . In this embodiment, the detection part 161 has three detection protrusions 1611, and the three detection protrusions 1611 are distributed along the center of the detection part 161 in a circle, and the axis of the piston rod of the cylinder 11 is arranged in line with the center of the detection part 161 Correspondingly, the number of connecting posts 15 is equal to the number of detecting protrusions 1611 , and the connecting posts 15 and the detecting protrusions 1611 are arranged coaxially. In addition, the lower end of the connecting column 15 is connected to the det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com