Inflation tube framework for greenhouse

An inflatable tube and greenhouse technology, which is applied in the field of greenhouse skeletons, can solve the problems of unfavorable energy saving and emission reduction, environmental protection, material cost and high construction cost, and is beneficial to energy saving and emission reduction, environmental protection, cost reduction and construction cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

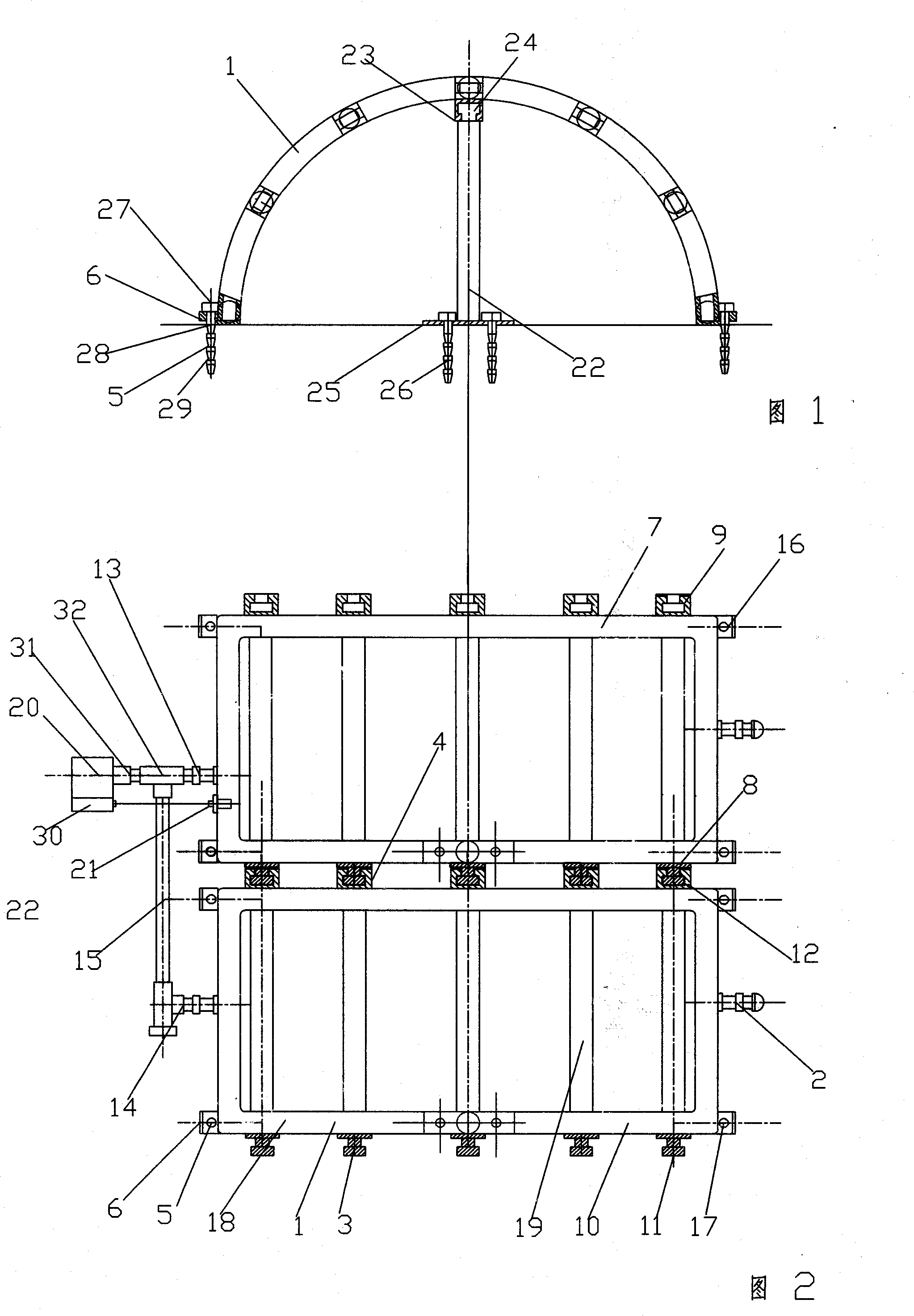

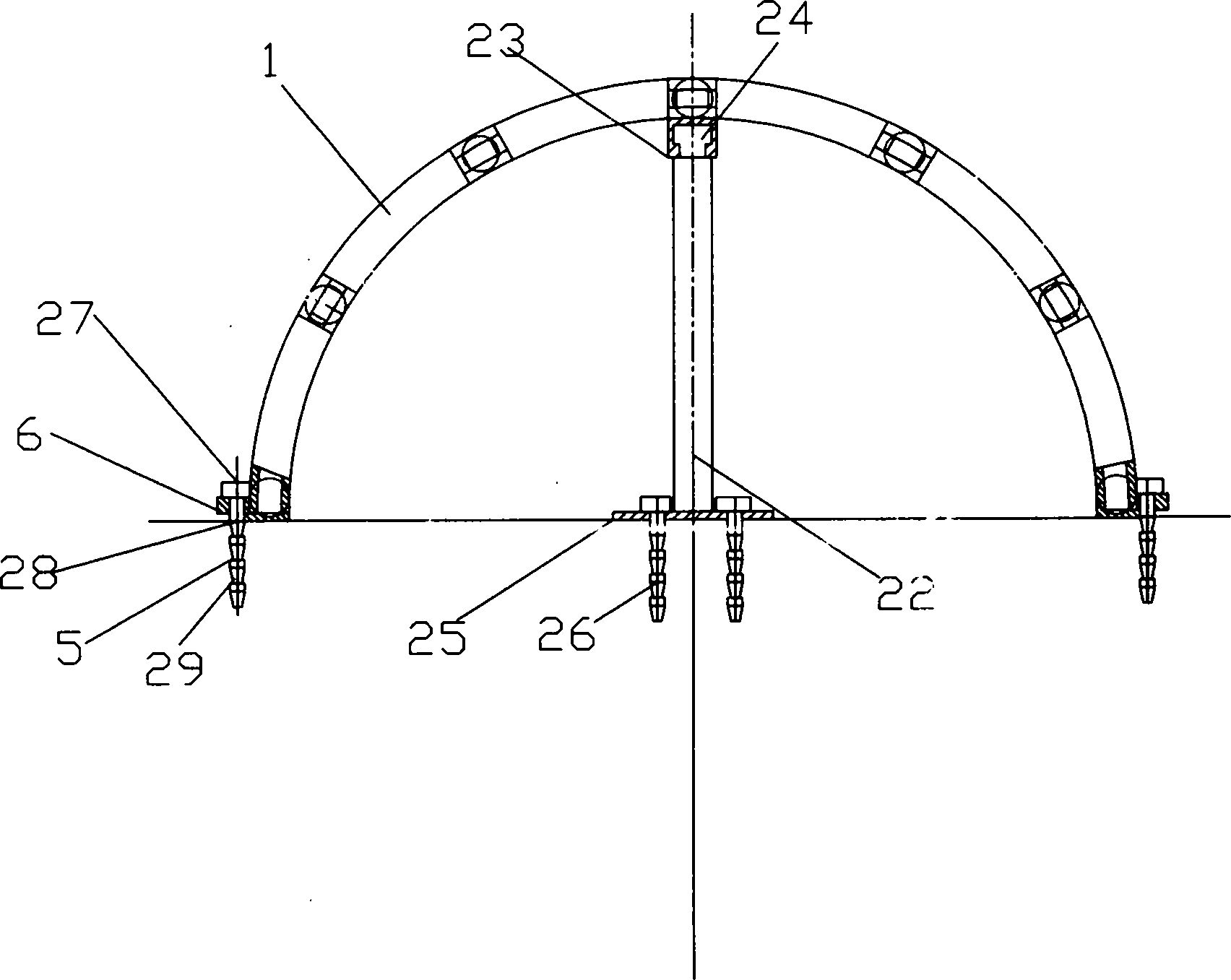

[0009] Below according to accompanying drawing and specific embodiment the present invention is further described:

[0010] figure 1 as well as figure 2 The schematic diagram of the skeleton structure of the greenhouse inflatable pipe is shown. The skeleton of the greenhouse inflatable pipe is composed of a sealed air network pipe 1, an air nozzle 2, a convex plug joint 3, a concave plug joint 4 and a ground rod 5; the front part of the air network pipe 1 is fixedly connected with The male plug connector 3 is fixedly connected with the female plug connector 4 at the rear of the gas network pipe 1, the protruding outer shape of the male plug connector 3 is the same as the concave shape of the female plug connector 4, and the male plug connector 3 and the female plug connector 4 are made of plastic; The air pipe 1 is connected with an air nozzle 3, which is used to inflate the air network pipe 1 to form the skeleton of the greenhouse inflatable pipe; the two ends of the air ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com