Harvester with straw crushing function

A straw crushing and harvester technology, which is applied in the field of harvesters and harvesters with straw crushing function, can solve the problems of corn harvesting and straw crushing that are not fundamentally solved by the working principle and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. The present embodiments are descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

[0021] In the following, the present embodiment takes a corn harvester as an example for description.

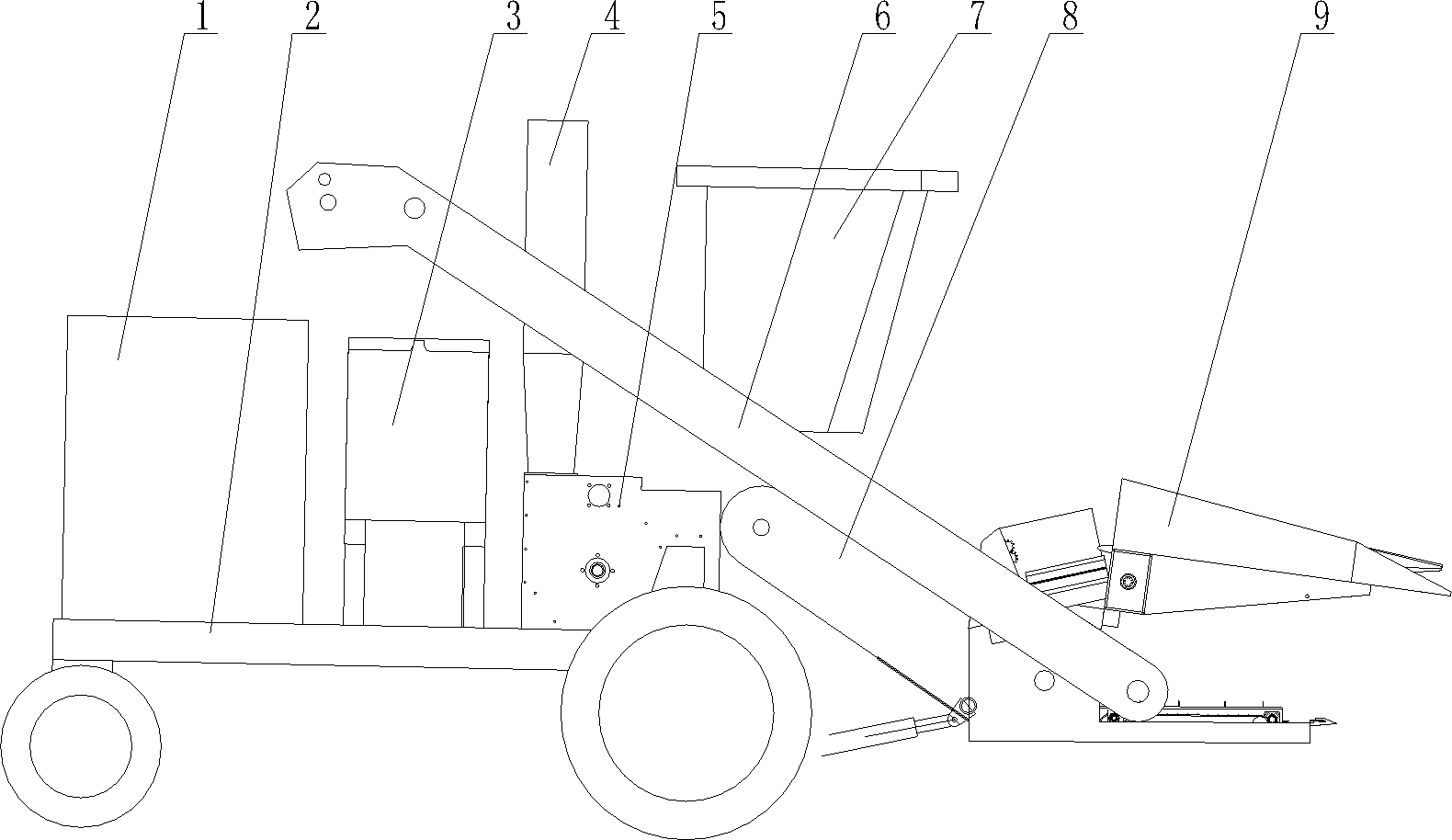

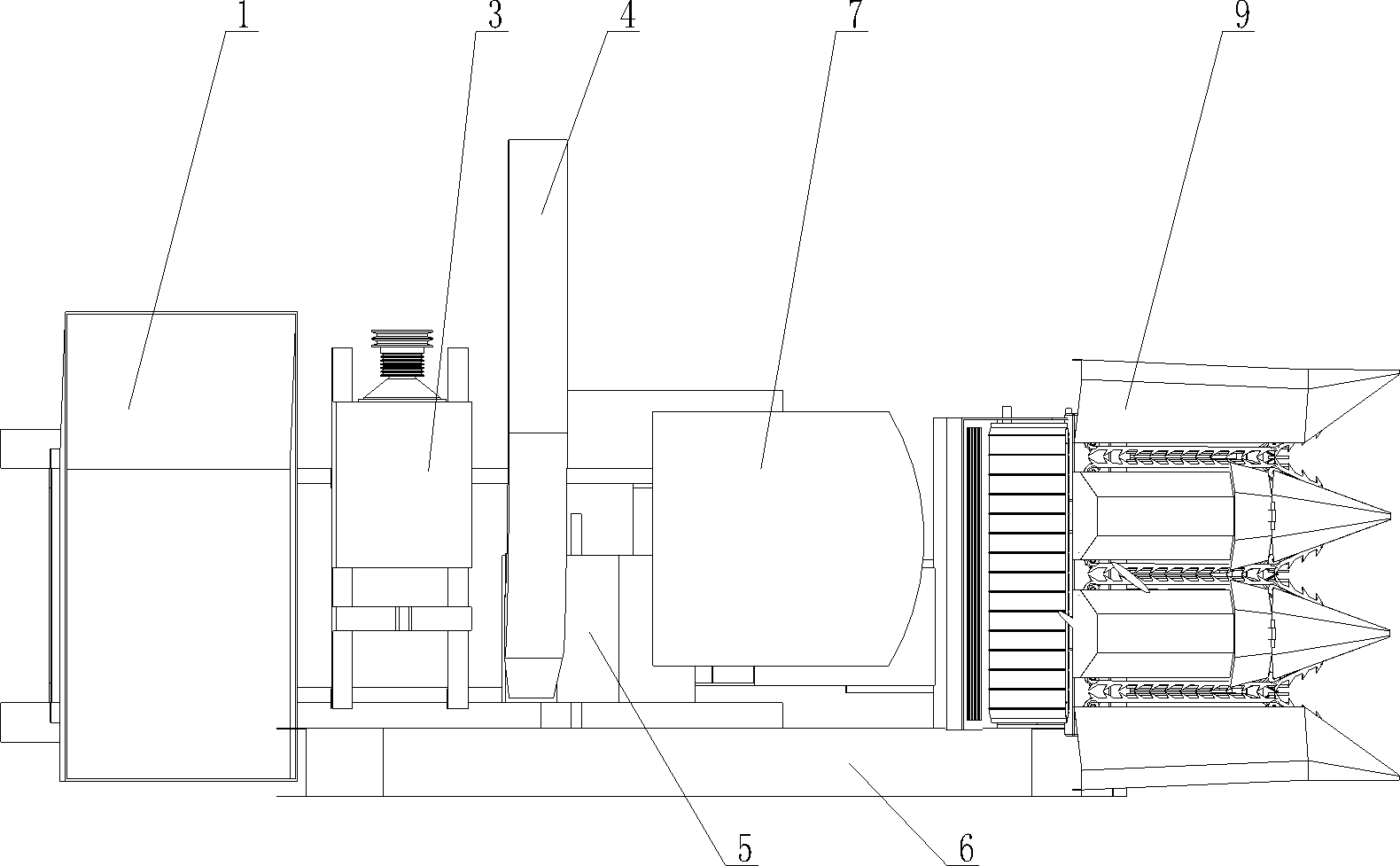

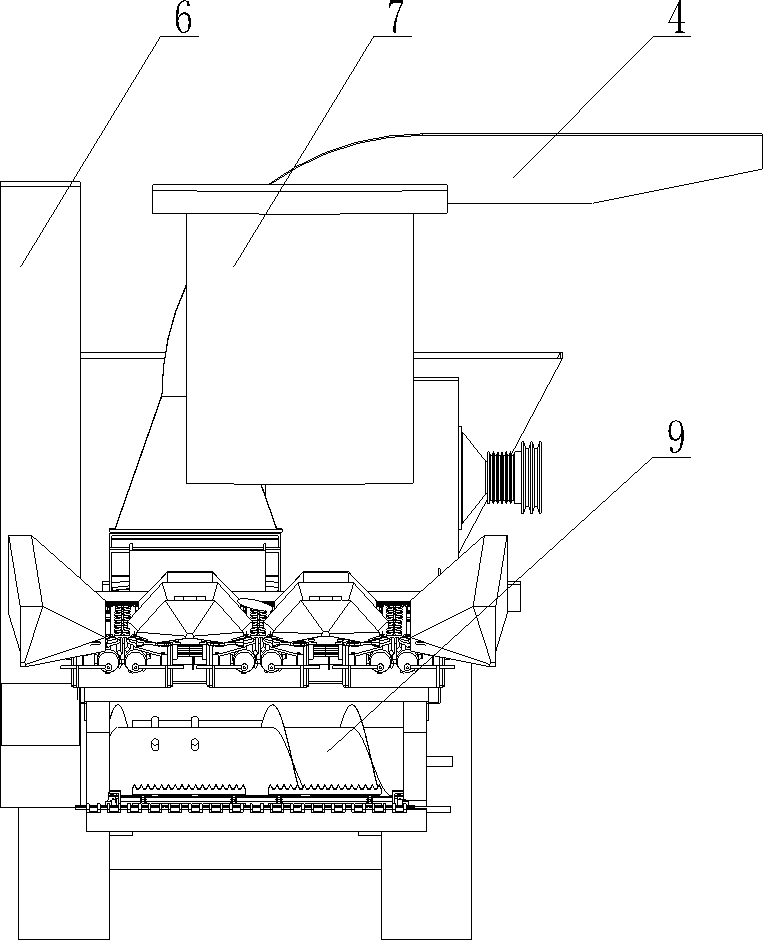

[0022] A harvester with a straw crushing function, comprising a vehicle 2, a cab 7, an engine 3, a header 9, a stem crushing device 5, a conveyor 8, an elevator 6, an ear box 1 and a throwing tube 4, according to the following Structural arrangement and function of the present invention, that is, corn harvesting, stalk processing and replacement of headers for its stalk class harvesting are described respectively.

[0023] Corn harvesting and straw processing: the vehicle engine is fixed in the middle of the vehicle, the ear box is hinged on the vehicle at the rear of the engine, the stalk crushing device is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com