Woven filter fabric for a band filter

A belt filter, filter technology, applied in membrane filters, fabrics, filtration and separation, etc., can solve the problem that filter cloth is not suitable for vacuum belt filter and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

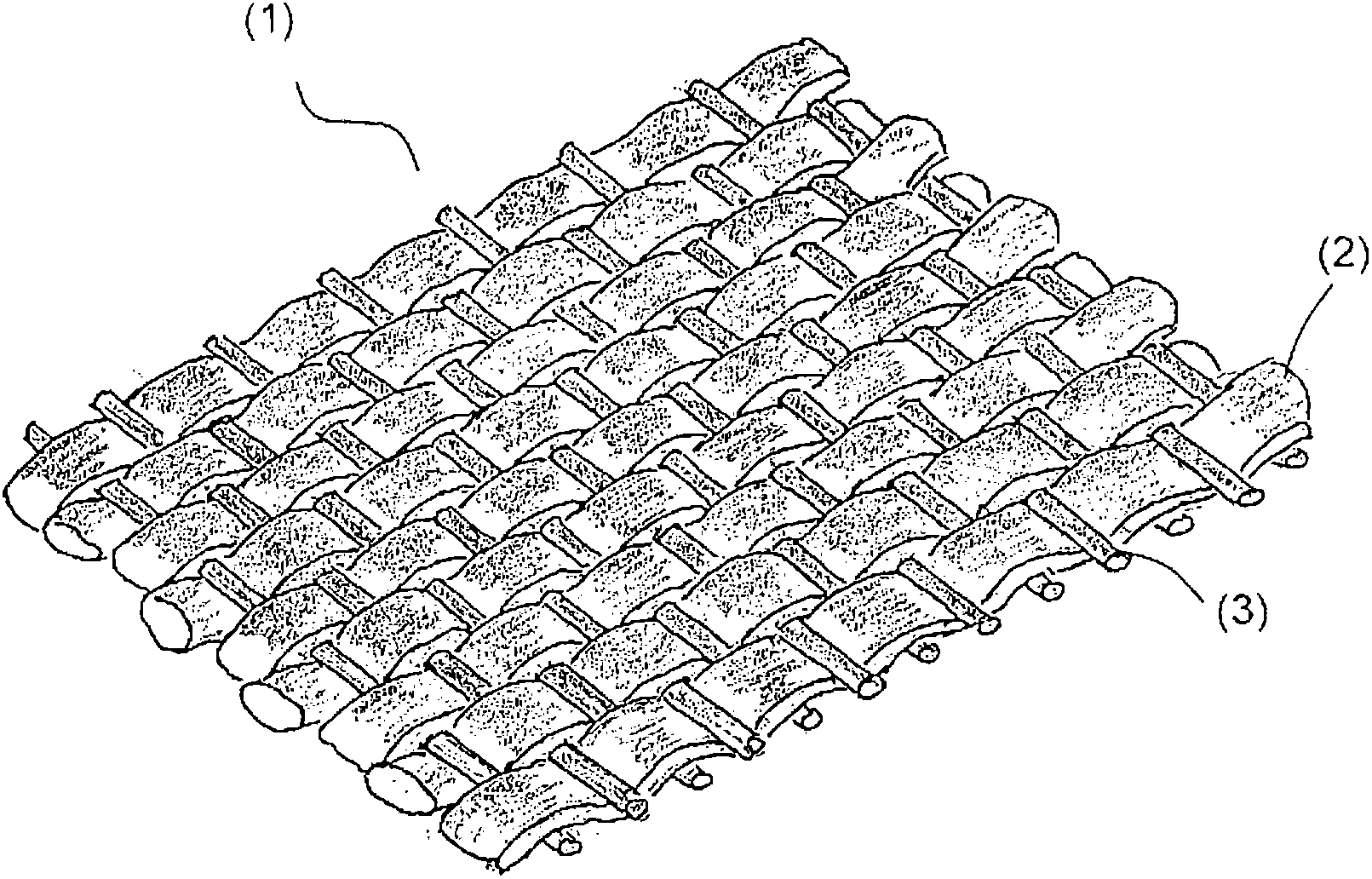

[0026] figure 1 The filter fabric 1 shown is made with a thickness of about 27 μm, with a thickness of 100 l / (min*dm 2 ), 200l / (min*dm 2 ) and 350l / (min*dm 2 ) of breathable PFA-monofilament-standard yarn (Standartfaden). Here, weft threads 2 and warp threads 3 are woven into a filter fabric 1 8000 mm long by 800 mm wide with 31 warp threads and 20 weft threads per 1 cm. After weaving, the filter fabric 1 was calendered three times to create breathability. Heat and pressure are brought into the fabric by hot and cold rolling. Here, the fabric was shrunk by about 10% to have 31 yarns per 0.7 cm, a length of 7000 mm, and a width of 700 mm.

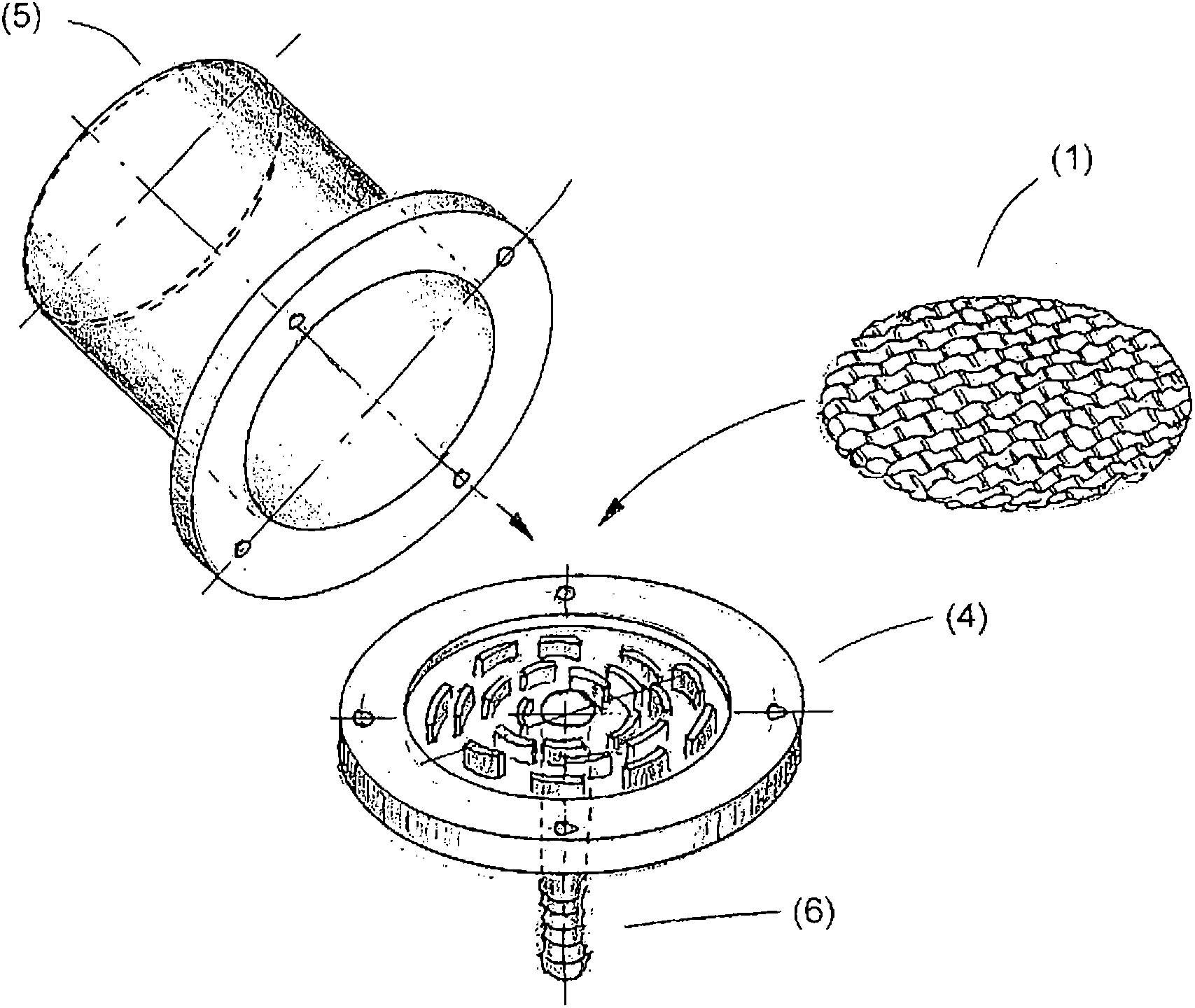

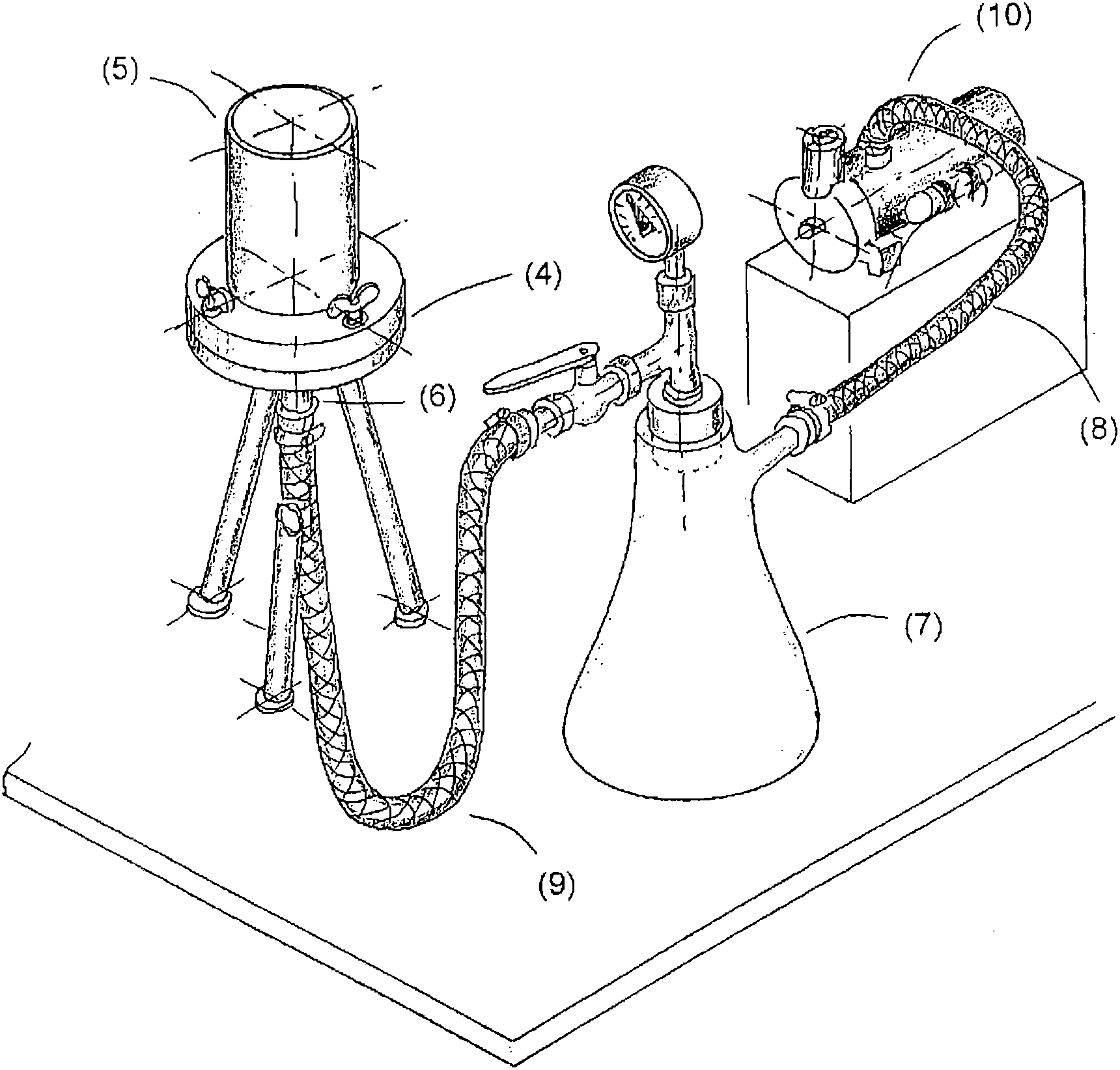

[0027] exist figure 2 The suction filter 4 with cover 5 shown in is an important part of the experimental setup for testing the filter fabric 1 . The filter fabric 1 is placed on the suction filter 4, and the suction filter 4 is screwed with the cover 5. The suction filter 4 has a suction pipe 6 in the lower region. A vacuum hose 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com