Mixed-excitation magnetic pole structure

A magnetic pole structure and hybrid excitation technology, applied in the field of magnetic pole structure and hybrid excitation magnetic pole structure, can solve the problems of increasing the complexity and cost of the control system, reducing the torque density of the motor, reducing the efficiency, etc. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The purpose and application of the present invention will be further described below in conjunction with specific examples.

[0028] refer to figure 1 , which is a schematic diagram of the stator pole structure of a common variable reluctance motor.

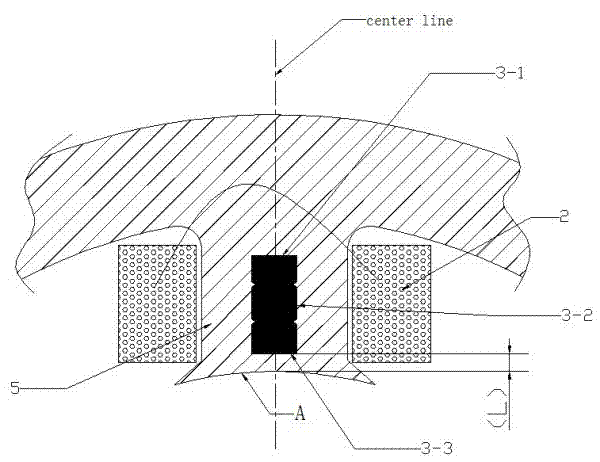

[0029] refer to figure 2 , is a schematic diagram of the hybrid excitation pole structure of the first specific embodiment of the present invention;

[0030] Including core magnetic pole (5), coil winding (2), permanent magnet (3), permanent magnet (3) is built in the magnetic pole (5), the end of permanent magnet (3) close to the core magnetic pole (5) pole surface A and the iron core The distance between the pole faces of the magnetic pole (5) is L, where L is greater than zero, and the magnetization direction of the permanent magnet is along the center line of the coil or the core pole center line. When the coil winding is not energized, the permanent magnet flux is in the core pole Closed, when the coil winding is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com