Device suitable for minim liquid mixed chemiluminescence reaction

A micro-volume liquid and chemiluminescence technology, which is applied in the direction of chemiluminescence/bioluminescence, and analysis by making materials undergo chemical reactions, can solve the problem of small sample volume, inconspicuous effect, and inability to complete micro-quantity and high-efficiency chemiluminescence reactions. Demand and other issues to achieve the effect of reducing energy loss and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

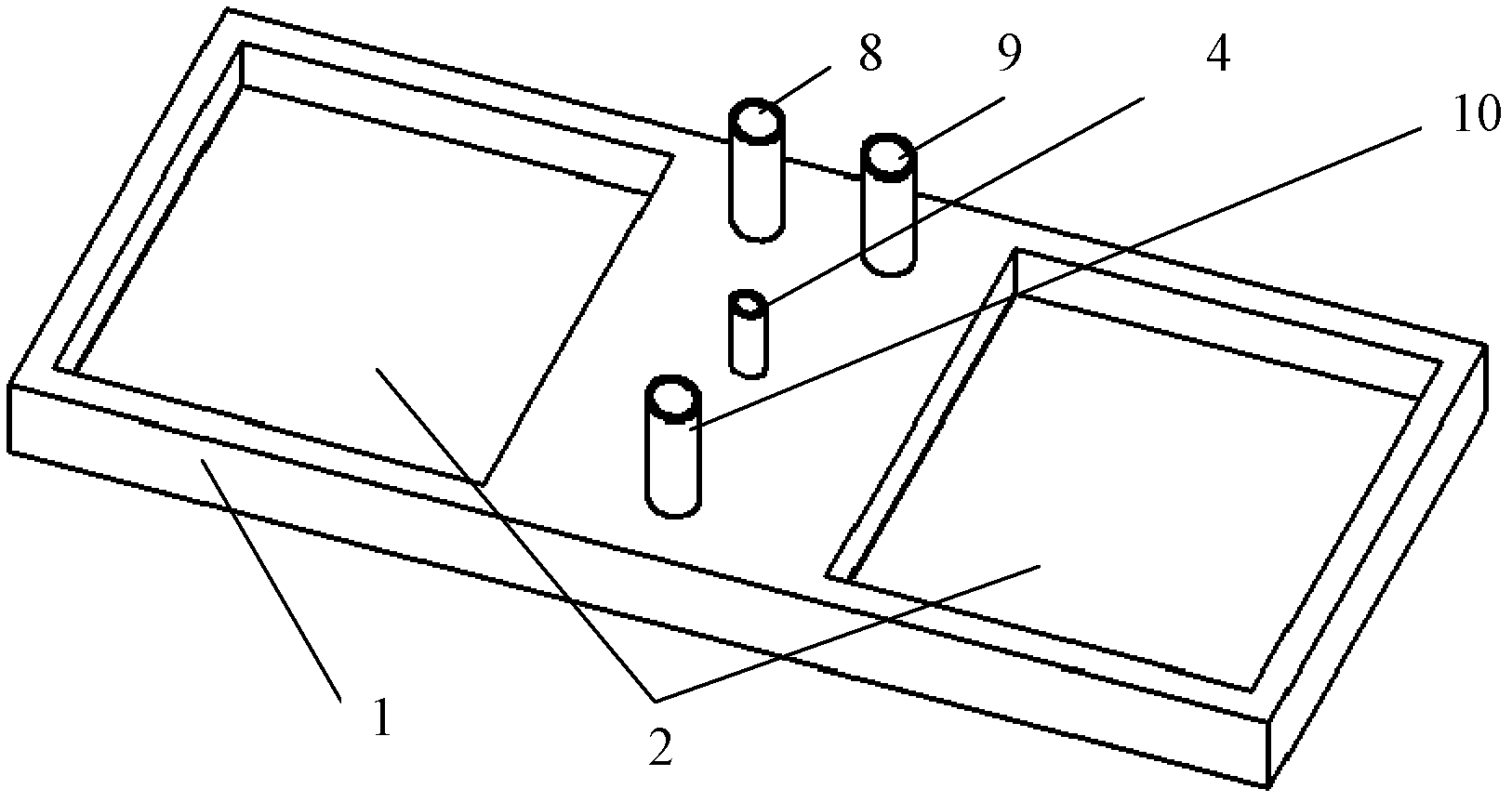

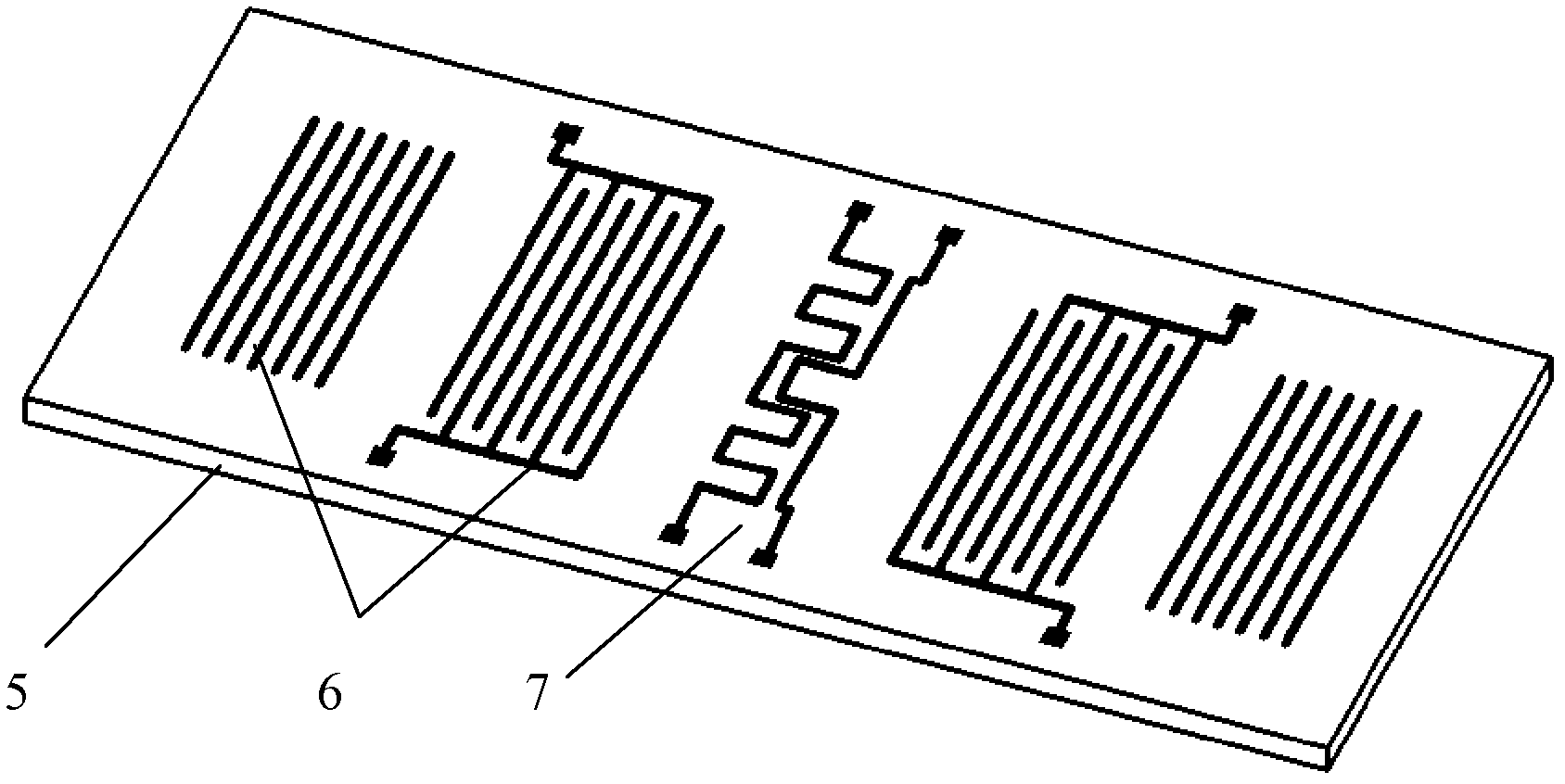

[0023] The device of the present invention is suitable for the mixed chemiluminescence reaction of trace liquid, and is composed of two plate-like structures, an upper cover plate 1 and a lower bottom plate 5 which are matched up and down.

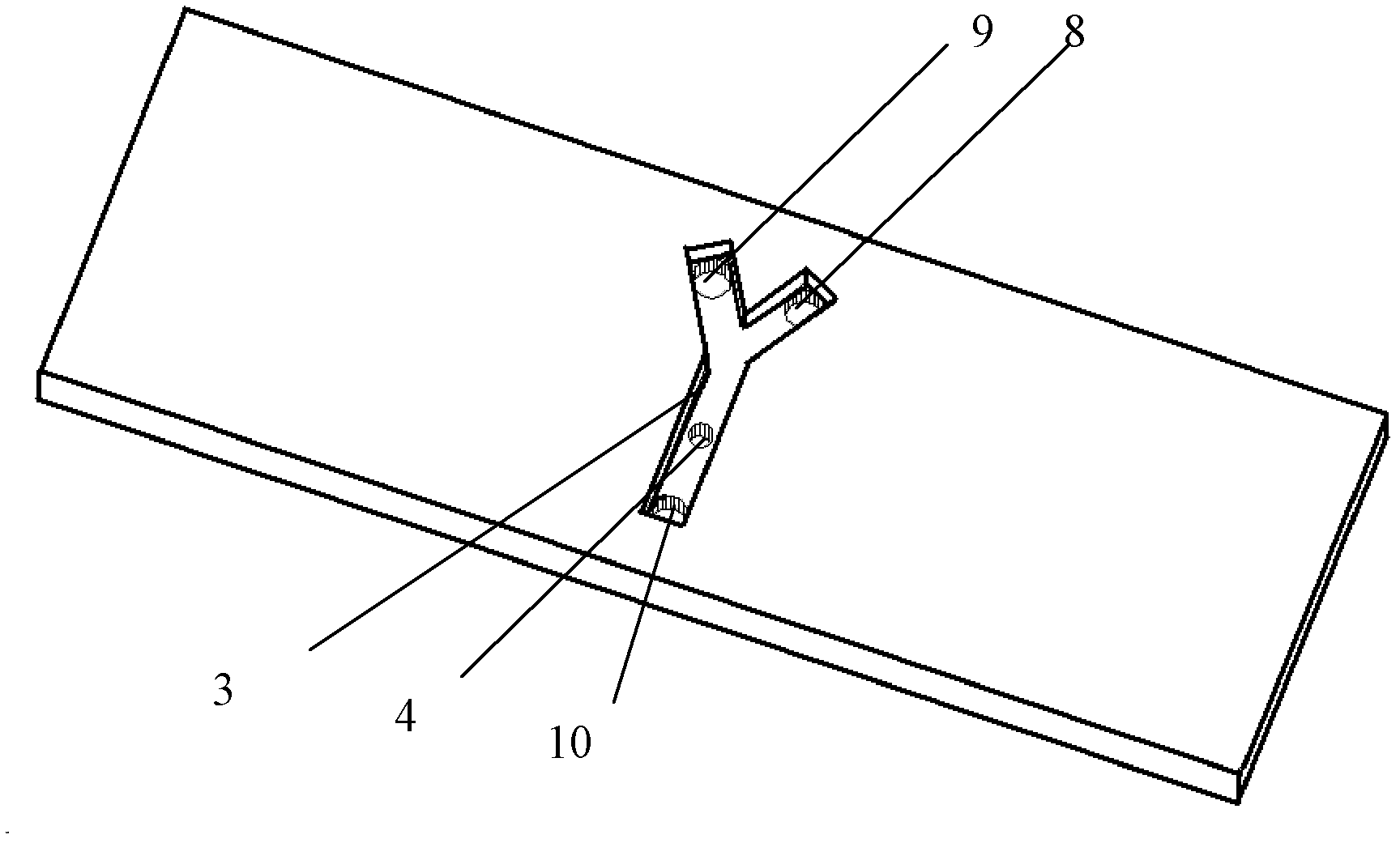

[0024] see figure 1 and figure 2 : The outer two ends of the upper cover plate 1 are provided with alcoves 2, and the inner middle part of the upper cover plate 1 is provided with a micro-channel structure 3 through which a small amount of liquid flows. The micro-channel structure 3 is a Y-shaped groove structure, and the micro-channel structure 3 is divided into sampling, mixing and waste liquid outflow parts; a light hole 4 is opened above the mixing part of the micro-channel structure 3, a sample inlet is provided above the sample injection part, and a waste liquid outlet 10 is provided above the waste liquid outflow part . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com