Core adhesive for flame-retardant steel wire rope core conveying belt and preparation method thereof

A technology of steel wire rope core and conveyor belt, applied in the direction of conveyor, transportation and packaging, can solve the problems of not getting large-scale production and use, and achieve the speed of oxidation and corrosion, strong ability to bond steel wire rope, and avoid hydrogen embrittlement corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

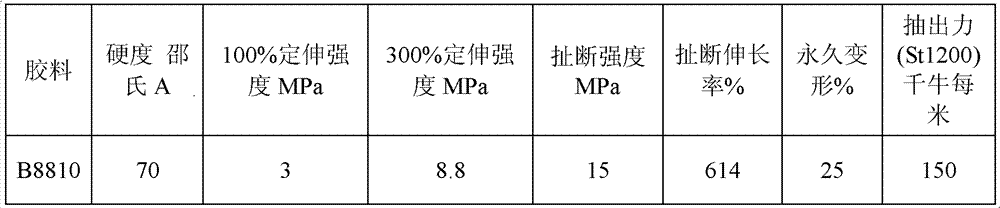

Examples

Embodiment 1

[0023] The preparation method of the core rubber for the flame-retardant steel cord conveyor belt comprises the following process steps in parts by weight:

[0024] (1) Mastication: Add 70 parts of natural rubber into the open mill, the mastication temperature is 50°C, and the time is 15 minutes;

[0025] (2) Mixing: Add the masticated natural rubber into the internal mixer, add 1 part of stearic acid, 1 part of activated magnesium oxide, 10 parts of reinforcing carbon black N22010, 5 parts of Qiangwei powder, and 1 part of coumarone , 1 part of aromatic oil, 1 part of tackifying resin, 1 part of cobalt salt, 5 parts of white carbon black, 1 part of coupling agent, 1 part of adhesive, 10 parts of 70# chlorinated paraffin, 5 parts of antimony trioxide and boric acid 10 parts of zinc, refining at 110°C for 3 minutes; then add 0.5 parts of insoluble sulfur, 0.5 parts of sulfur, 3 parts of zinc oxide, 1 part of anti-aging agent RD, 1 part of anti-aging agent 4010NA, 1 part of acce...

Embodiment 2

[0034] The preparation method of the core rubber for the flame-retardant steel cord conveyor belt comprises the following process steps in parts by weight:

[0035] (1) Masticating: Add 100 parts of natural rubber into the open mill, the masticating temperature is 80°C, and the time is 25 minutes;

[0036] (2) Mixing: Add the masticated natural rubber into the internal mixer, add 4 parts of stearic acid, 5 parts of activated magnesium oxide, 30 parts of reinforcing carbon black N220, 30 parts of Qianwei powder, and 5 parts of coumarone , 5 parts of aromatic oil, 5 parts of tackifying resin, 3 parts of cobalt salt, 15 parts of white carbon black, 5 parts of coupling agent, 5 parts of adhesive, 40 parts of 70# chlorinated paraffin, 20 parts of antimony trioxide and boric acid 40 parts of zinc, refining at 130°C for 5 minutes; then add 2.5 parts of insoluble sulfur, 2.5 parts of sulfur, 8 parts of zinc oxide, 4 parts of anti-aging agent RD, 4 parts of anti-aging agent 4010NA, 3 p...

Embodiment 3

[0042] The preparation method of the core rubber for the flame-retardant steel cord conveyor belt comprises the following process steps in parts by weight:

[0043] (1) Mastication: Add 85 parts of natural rubber into the open mill, the mastication temperature is 70°C, and the time is 20 minutes;

[0044](2) Mixing: Add the masticated natural rubber into the internal mixer, add 3 parts of stearic acid, 3 parts of activated magnesium oxide, 120 parts of reinforcing carbon black N220, 15 parts of Qiangwei powder, and 3 parts of coumarone , 3 parts of aromatic oil, 3 parts of tackifying resin, 2 parts of cobalt salt, 10 parts of white carbon black, 3 parts of coupling agent, 3 parts of adhesive, 25 parts of 70# chlorinated paraffin, 10 parts of antimony trioxide and boric acid 20 parts of zinc, refining at 120°C for 4 minutes; then add 2 parts of insoluble sulfur, 2 parts of sulfur, 5 parts of zinc oxide, 2 parts of anti-aging agent RD, 2 parts of anti-aging agent 4010NA, 2 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com