Double-material arm charging and blanking mechanism for grinding machine

A material arm and grinding machine technology, which is applied in the field of double material arm loading and unloading mechanisms for grinding machines, can solve the problems of production progress impact, high grinding cost, grinding process stagnation, etc., to ensure production progress, smooth grinding process, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

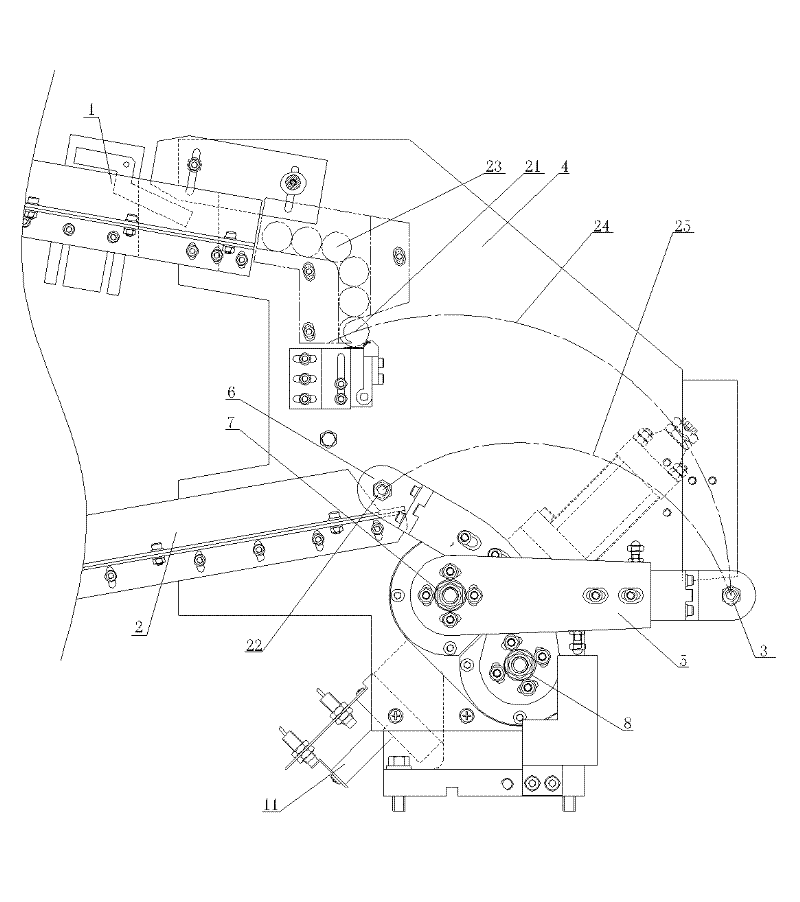

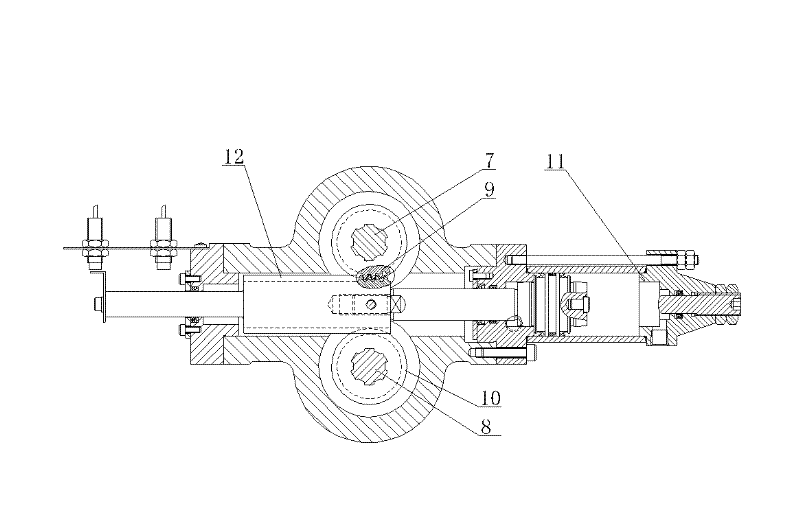

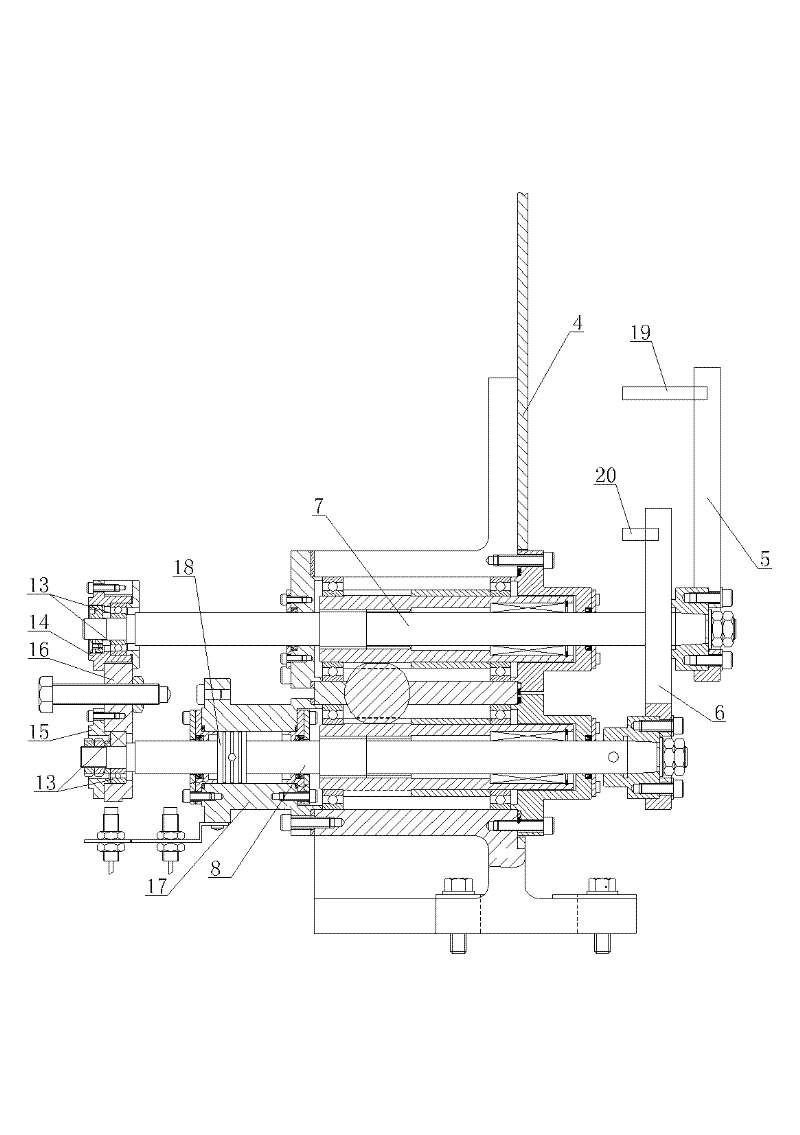

[0011] See figure 1 , figure 2 , image 3 , which includes an upper material channel 1, an lower material channel 2, a grinding position 3 of a grinder, a panel 4, and a loading arm 5. The upper material channel 1 and the lower material channel 2 are respectively placed on the front side of the panel 4, and it also includes a lower The material arm 6, the loading arm 5 and the unloading arm 6 are located on the front side of the panel 4, and the rotary centers of the loading arm 5 and the unloading arm 6 are equipped with a loading rotary shaft 7 and a blanking rotary shaft 8 respectively. The rotating shaft 7 and the blanking rotary shaft 8 all run through the panel 4, and the rear side of the loading rotary shaft 7 and the blanking rotary shaft 8 are respectively equipped with a loading gear 9, a blanking gear 10, and a material arm rotary cylinder 11. The driving end is equipped with a rack 12, and the teeth on both sides of the rack 12 respectively mesh with the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com