Casting machine

A casting machine and frame technology, applied in the field of casting machines, can solve problems such as shortening production takt time, and achieve the effect of shortening production takt time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Hereinafter, the present invention will be specifically described based on illustrated embodiments.

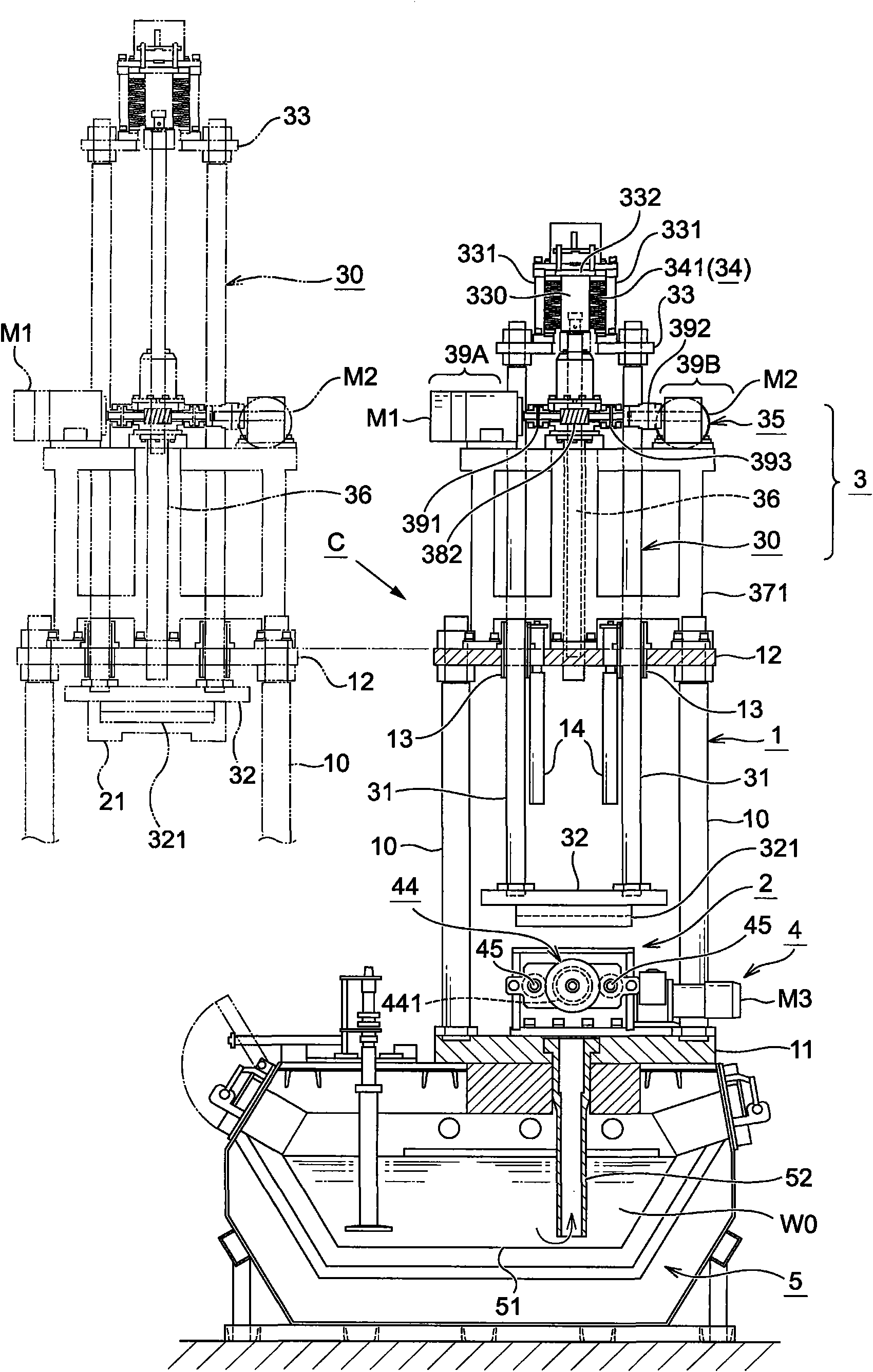

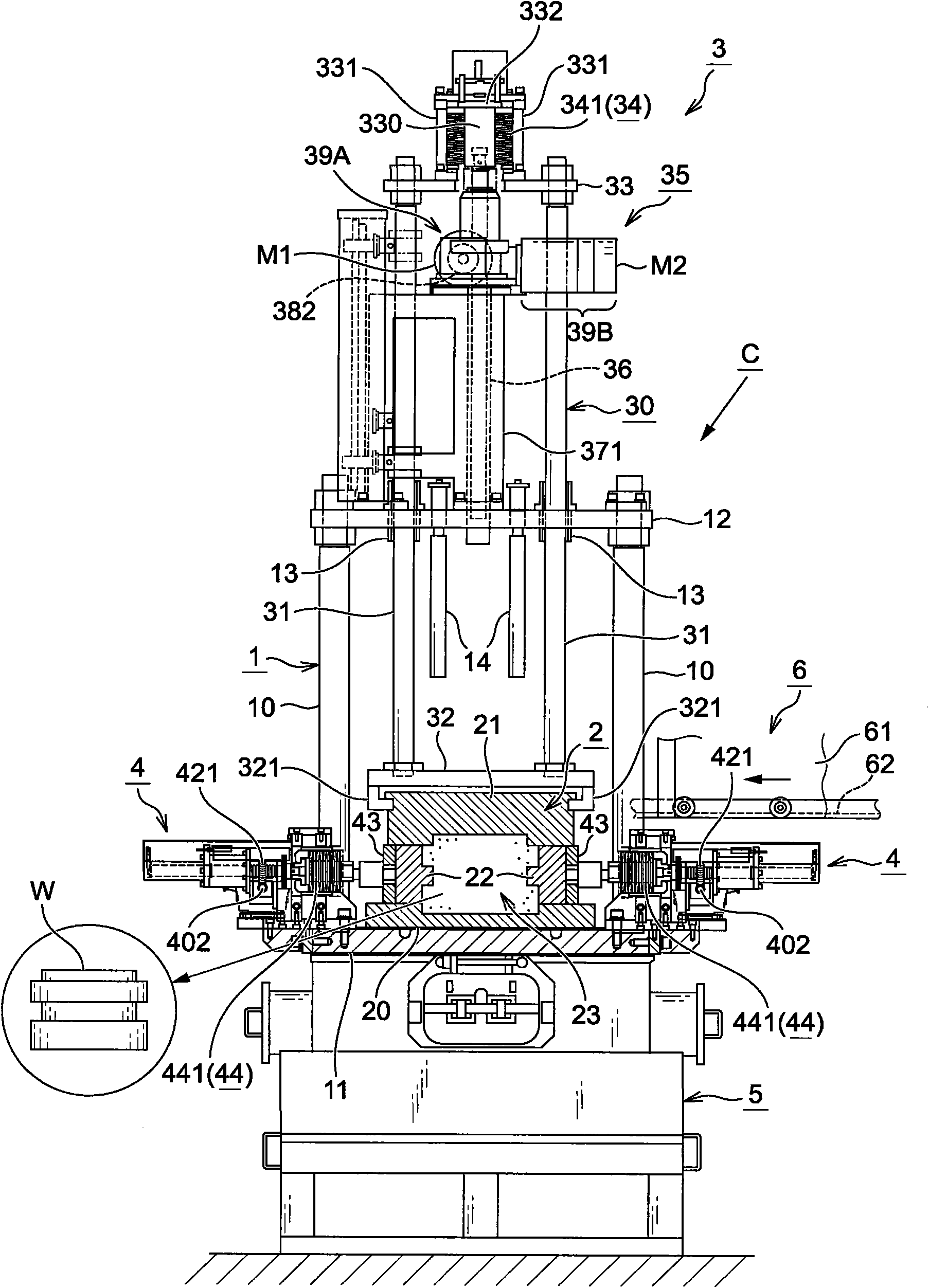

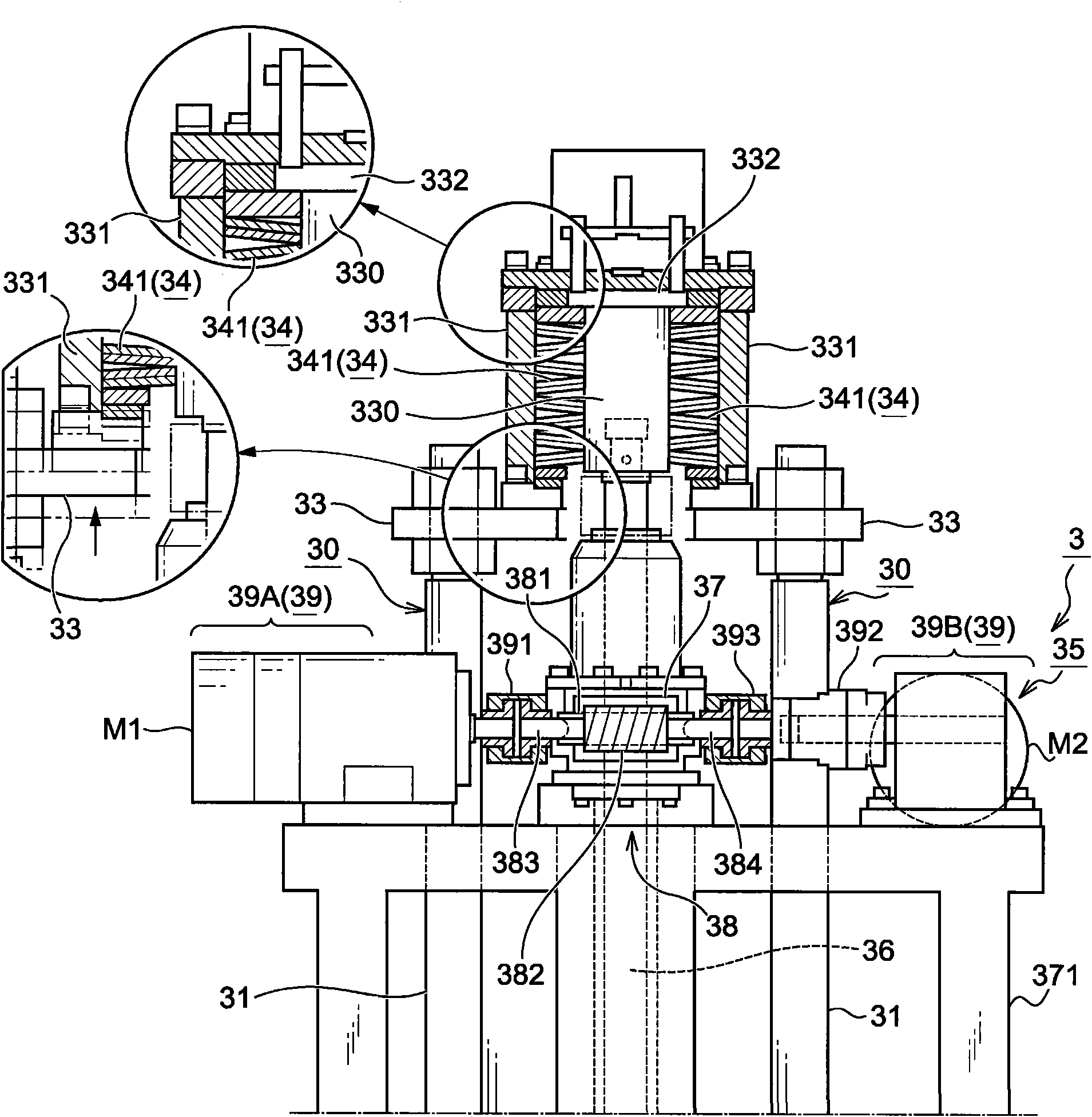

[0025] The casting machine C of the present invention comprises: a frame 1; a mold device 2 supported on the frame 1; a lifting device 3 for driving the upper mold 21 of the mold device 2 to lift; a transverse mold 22 for driving the mold device 2 A lateral moving device 4 for lateral movement; a liquid storage device 5 that communicates with the lower mold 20 of the mold device 2 and is arranged below the frame 1 ; and an unloading device 6 for unloading manufactured workpieces W.

[0026] First, rack 1 will be described.

[0027] As an example, the frame 1 is a frame-shaped member that integrally supports a base support plate 11 and an upper support plate 12 arranged above the base support plate 11 in a layered manner by utilizing four columns 10 . Metal sliding pipes 13 for supporting the lifting device 3 are provided. In addition, a workpiece take-out lever 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com