Self-cleaning high-flow gas filtering apparatus

A filter device and high-flow technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of small gas treatment capacity, time-consuming installation and disassembly of filter cartridges, and large equipment resistance, so as to improve filtration efficiency , reduce the filtration rate, increase the effect of backwash cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

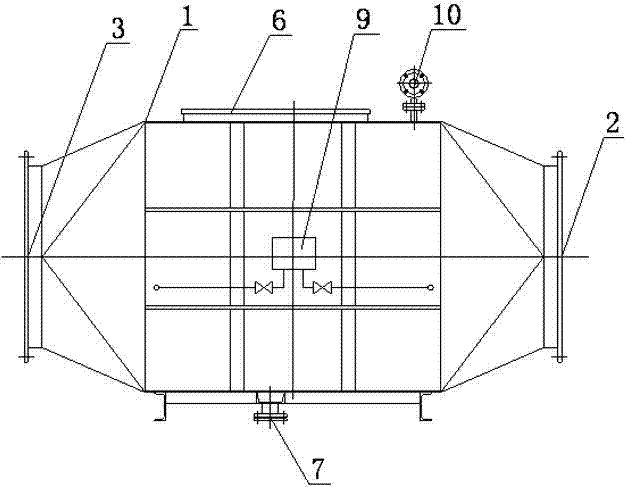

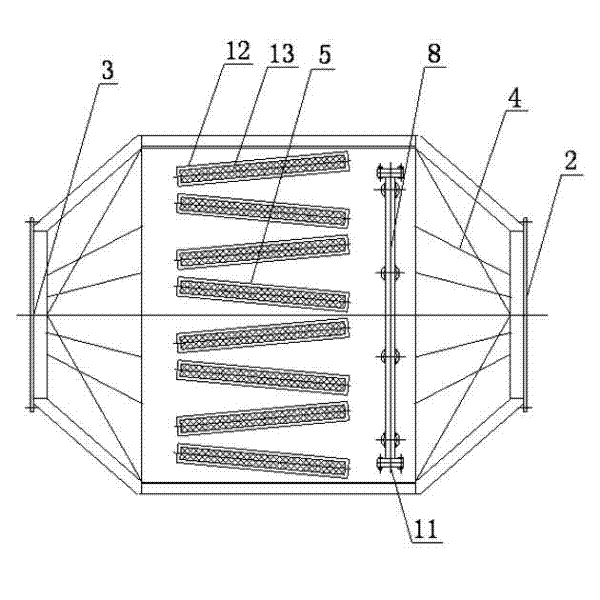

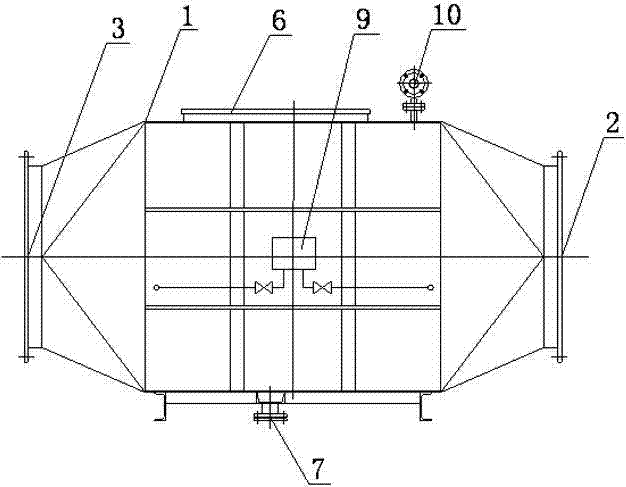

[0014] Such as figure 1 with figure 2 As shown, the self-cleaning large-flow gas filter device of the present invention includes a gas filter body 1, one end of the gas filter body 1 is provided with a gas inlet 2, the other end of the gas filter body 1 is provided with a gas outlet 3, and a gas inlet 2 There are diversion grids 4 at the gas outlet and the gas outlet 3, and a filter device 5 is provided in the gas filter body 1. The filter device 5 includes a plurality of filter elements 12, and a filter net 13 is arranged in the filter element 12, and the filter elements 12 are connected end to end in sequence. Form a W shape, the top of the filter device 5 is provided with a filter outlet 6, the bottom of the filter device 5 is provided with a sewage outlet 7, and one side of the filter device 5 is provided with an automatic spray flushing device 8, which is connected with the gas filter The pressure difference display instrument 9 outside the main body 1 is connected, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com