Nut husking device

A nut and drive shaft technology, applied in the field of plant and fruit processing machinery, can solve the problems of high production cost, loss of nutrients, expensive equipment, etc., and achieve the effects of complete and beautiful appearance, high work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

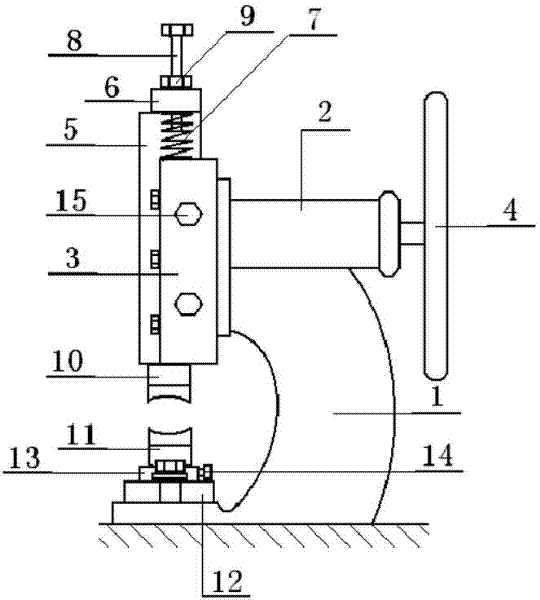

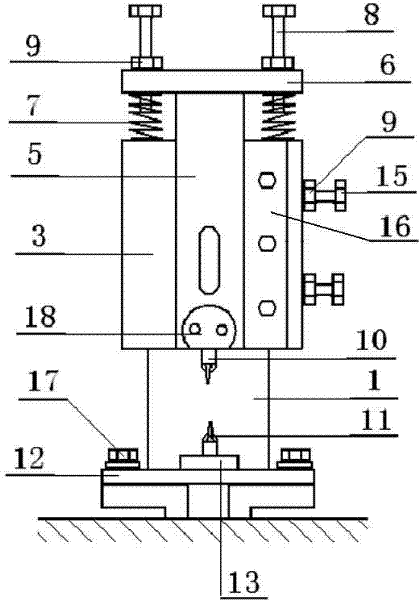

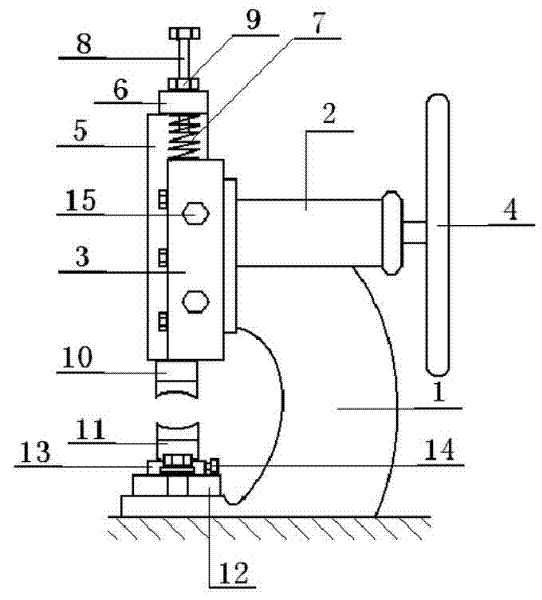

[0010] Such as figure 1 , 2 As shown, the present invention includes a frame 1, a transmission shaft seat 2, an operating hand wheel 4, a guide seat 3, a movable knife rest 5, a moving knife device and a static knife device, and the transmission shaft seat is arranged on the top of the frame 1 2. A guide seat 3 is set at one end of the transmission shaft seat 2, and the guide seat 3 is dynamically matched with the movable tool holder 5. One end of the transmission shaft matched with the transmission shaft seat 2 is provided with an operating hand wheel 4, and the other end of the transmission shaft is connected with the movable tool holder through the transmission gear. 5. Dyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com