Motor rotor body

A technology of motor rotor and rotor shaft, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of stress concentration, easy falling off of magnetic steel, weak anti-deformation ability, etc. The effect of reducing and improving mechanical strength and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

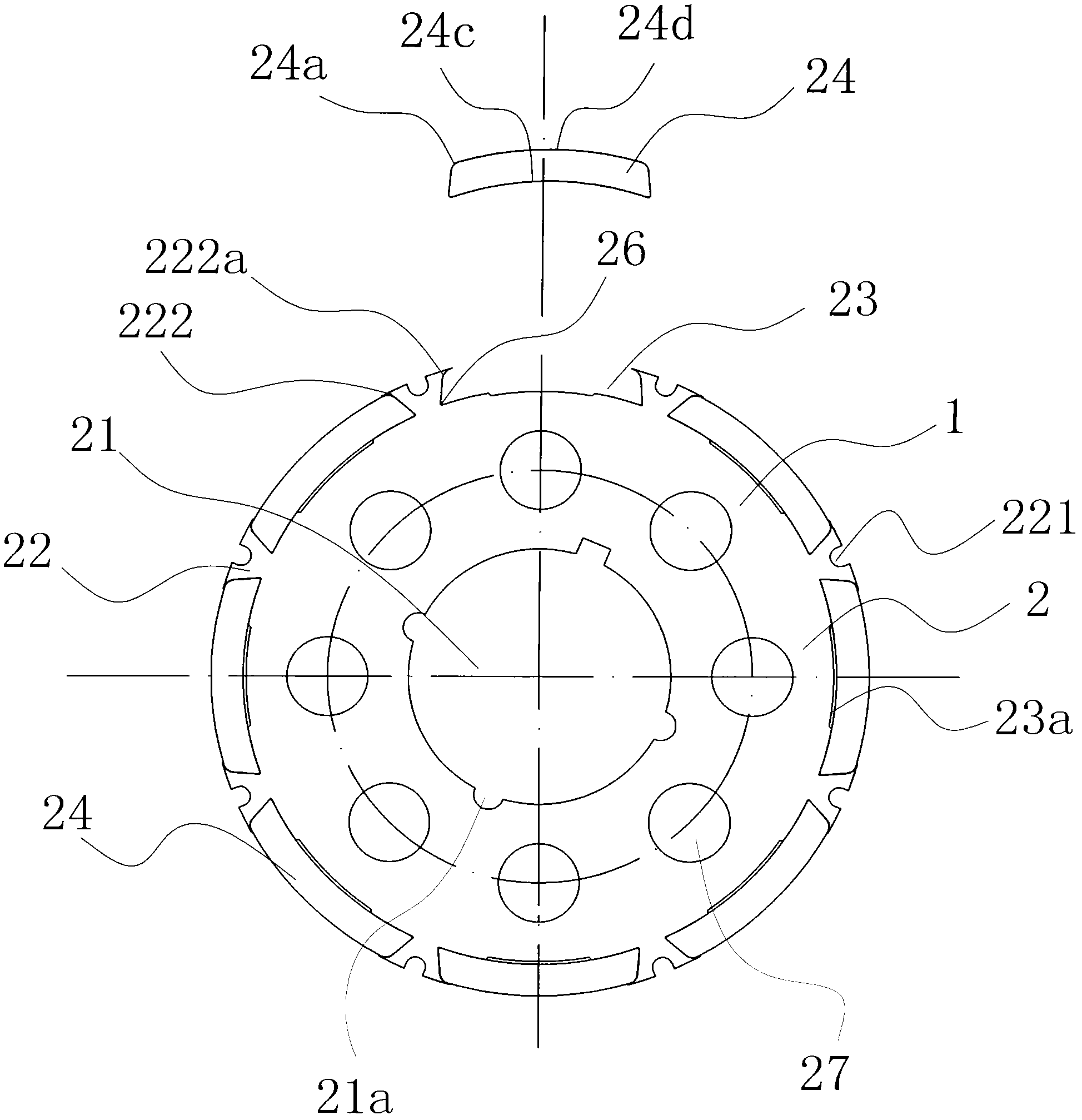

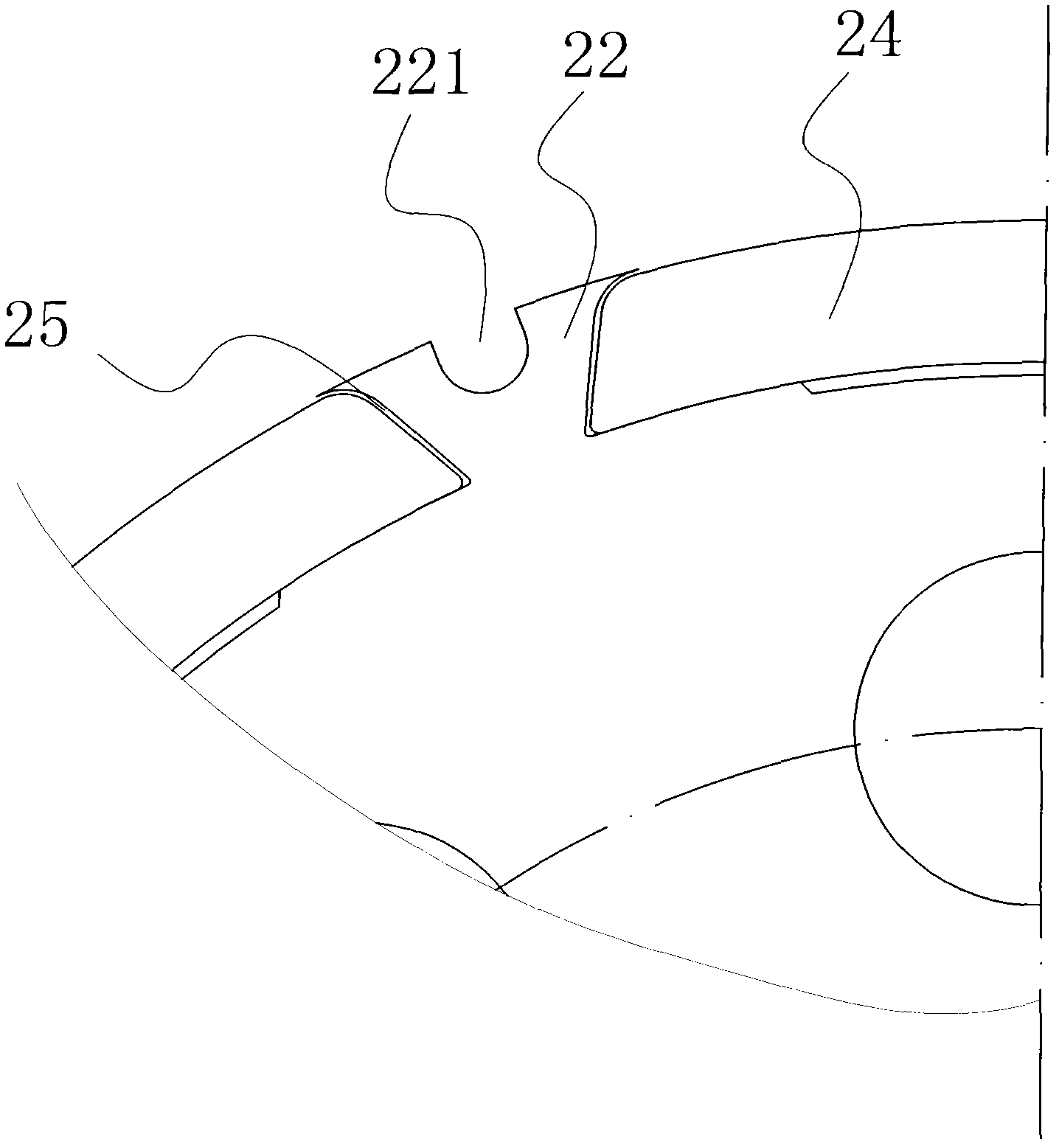

[0025] Such as figure 1 , 3 As shown, the rotor body of this motor includes a body 2 formed by stacking several rotor pieces 1. The center of the body 2 has a central hole 21 for fixing the rotor shaft. There are several outer ends and larger inner ends on the outer edge of the body 2. Small and evenly distributed dovetail bodies 22 in the circumferential direction, a dovetail groove 23 with a small outer end and a large inner end is formed between two adjacent dovetail bodies 22, a magnetic steel body 24 is housed in the dovetail groove 23, and a magnetic steel body 24 is housed in the dovetail body 22. There is a groove body 221 which can eliminate the gap 25 between the magnetic steel body 24 and the dovetail body 22 when it is expanded under the action of an external force, so that the magnetic steel body 24 is fixed in the dovetail groove 23 . On both sides of the outer end of the dovetail body 22 are respectively provided blocking feet 222 buckled on the outer feet of t...

Embodiment 2

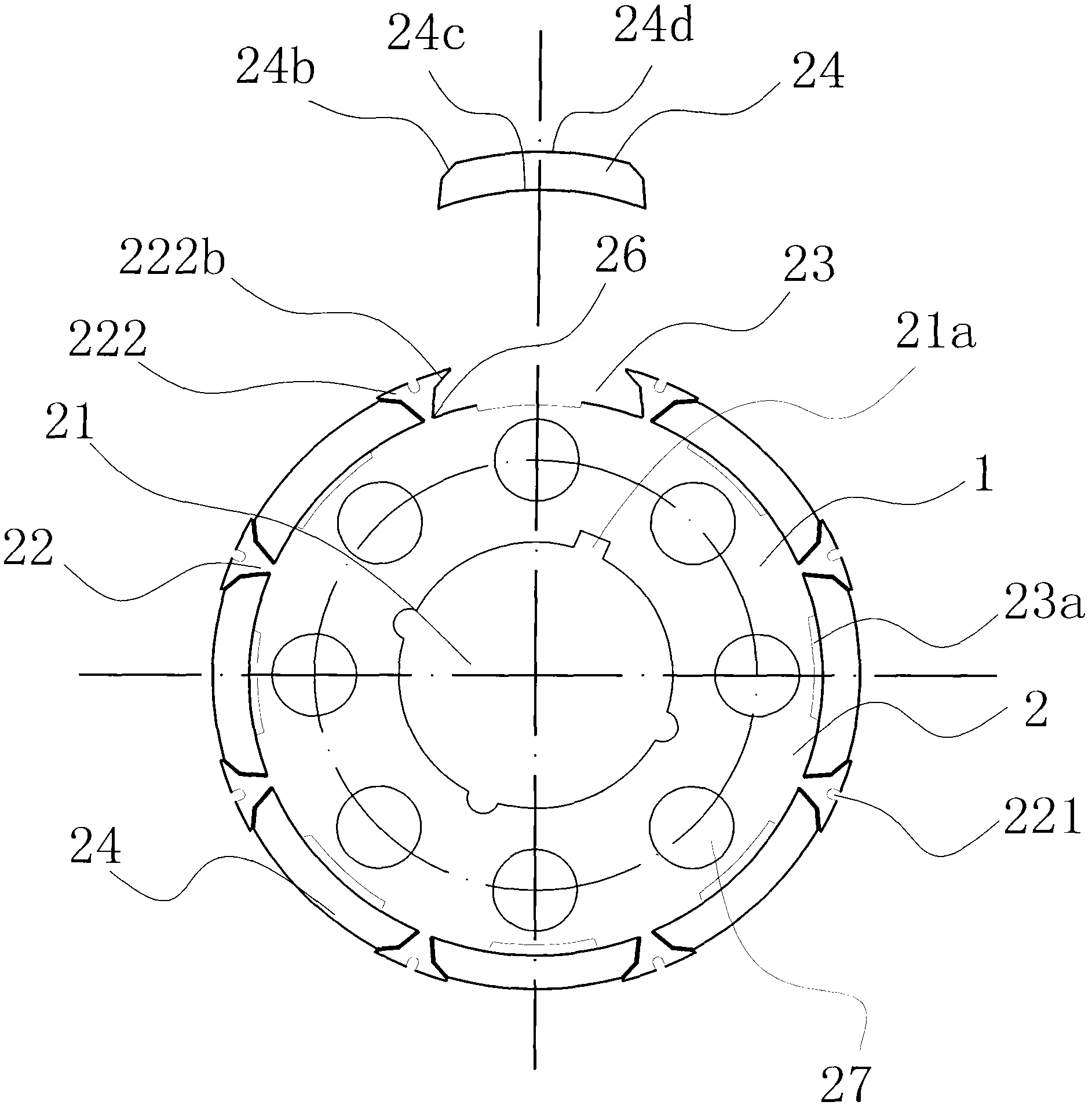

[0029] Such as figure 2 , 3 As shown, the inner surface of the blocking leg 222 has a first slope 222b, and the outer leg of the magnetic steel body 24 has a second slope 24b, and the above-mentioned first slope 222b coincides with the second slope 24b. In this embodiment, since the inner side of the blocking foot 222 has a first slope 222b, and the outer leg of the magnetic steel has a second slope 24b, the slope greatly increases the contact surface between the dovetail body 22 and the magnetic steel body 24, and the contact surface A large increase can better disperse the stress. When the groove body 221 is expanded under the action of an external force, the dovetail body 22 and the magnetic steel body 24 are closely fitted, that is, the first slope 222b coincides with the second slope 24b. At this time, The blocking feet 222 are also fastened to the outer feet of the magnetic steel body 24, so that the magnetic steel body 24 is firmly fixed in the dovetail groove 23, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com