Breaker manipulator

A technology for manipulating arms and circuit breakers, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve problems such as uneven contact and reduced working stability of circuit breakers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

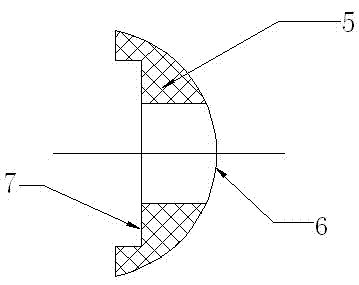

[0012] like figure 1 As shown, the operating arm of the circuit breaker includes an operating arm 1 and a push rod 2 connected with the moving contact part of the vacuum interrupter. The operating arm swings around its installation fulcrum. The rear end of the rod passes through the piercing hole 4 provided in the center of the hemispherical depression 3, and a limit nut is installed at the rear end of the push rod 2, and a compression spring 8 is pressed between the operating arm 1 and the step in the middle of the push rod 2; A wear-resistant block 5 cooperating with it is arranged in the depression 3, and the center of the wear-resistant block is provided with a central hole for the push rod to pass through, and the rear end of the compression spring 8 is pressed on the front end face of the wear-resistant block. like figure 2 As shown, the rear end of the wear block 5 is a hemispherical surface 6 matched with the hemispherical recess 3 . The front end face of the wear-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com