Testing apparatus of axial load loading of gear case and testing method thereof

A loading test device and axial load technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem of inability to load the gearbox axial load test, etc., and achieve the effects of reducing vibration, improving test accuracy and improving test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

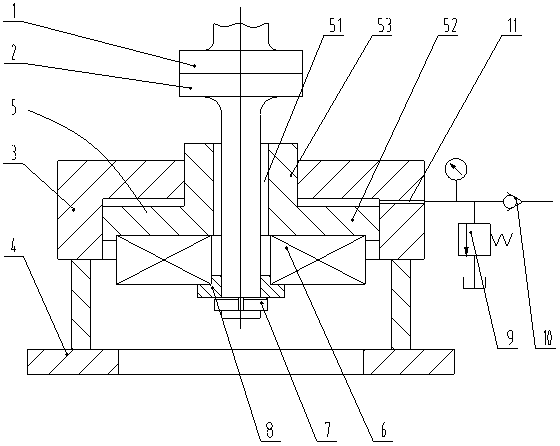

[0023] Embodiment 1: as figure 1 As shown, a vertical gearbox axial load loading test device includes a hydraulic cylinder, and the hydraulic cylinder includes a cylinder body 3 and a piston 5 arranged in the cylinder body 3 . The piston 5 is provided with a connection through hole 51, and the connection through hole 51 is provided with a connecting rod assembly 2 for connecting with the output flange 1 of the gearbox. The connecting rod assembly 2 is sequentially fitted with a spherical roller thrust bearing 6 , a bearing baffle 8 and a round nut 7 , and the thrust bearing 6 is arranged close to the end surface of the piston 5 .

[0024] In this embodiment, the connecting rod assembly 2 is loosely fitted with the connecting through hole 51, so that the connecting rod assembly can rotate together with the output shaft and the piston does not rotate, so that the power loading test and the thrust loading test can be performed simultaneously.

[0025] In this embodiment, the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com