Slip form construction device and method for single concrete pump in synchronous multi-bin number pouring

A technology of concrete pump and construction device, which is applied in formwork/formwork/work frame, processing of building materials, preparation of building components on site, etc., can solve the problems of slow concrete pouring, large labor input, poor construction quality, etc. , to achieve the effect of high construction efficiency, low input cost, convenient installation and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

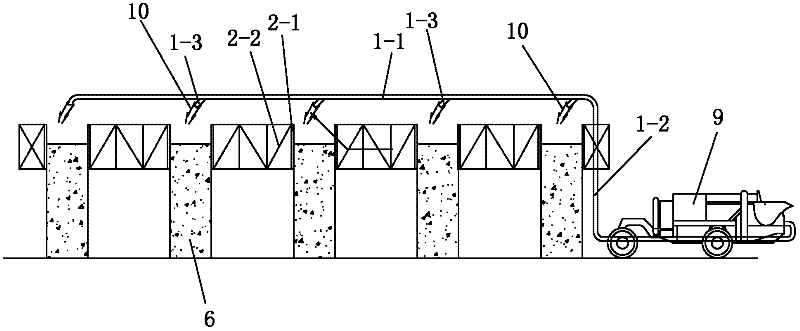

[0038] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the slipform construction device of the present invention includes a concrete pumping device, a concrete pumping pipeline connected to the concrete pumping device, and a slipform that performs slipform construction on a plurality of concrete structures to be poured respectively, The number of the sliding forms is multiple and the number is the same as the number of the concrete structures to be poured. The sliding form includes a sliding form panel 2-1, a panel support frame for supporting and fixing the sliding form panel 2-1, and a lifting device for integrally lifting the sliding form panel 2-1 and the panel support frame. The formwork panel 2-1 is a molding formwork whose internal molding cavity structure is the same as that of the concrete structure to be poured to be formed, and the panel support frame is supported and fixed on the outside of the sliding formwork panel 2-1 and is connected with the sl...

Embodiment 2

[0075] combine Figure 5 , in this embodiment, the sliding form construction device adopted is different from Embodiment 1 in that: the control ram is an electric control ram, and the number of the electric control ram is multiple and its number is the same as that of the described The number of concrete branch pumping pipes is the same. The electric control ram includes a blocking plate that blocks the lower port of the concrete branch pumping pipeline and an electric driving mechanism 3-2 that drives the blocking plate to move back and forth. The mechanism is connected to the blocking plate, and the electric driving mechanism drives the moving of the blocking plate to control and adjust the opening and closing states of the concrete branch pumping pipeline or the pumping flow of the pipeline accordingly.

[0076] At the same time, in this embodiment, the sliding form construction device adopted also includes an automatic monitoring system. The automatic monitoring system i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com