Concrete-filled steel tube column provided with soft steel bushing and embedded with high-tenacity material and manufacturing method thereof

A high-toughness technology for concrete filled steel tubular columns, which is applied in the processing of building materials, columns, piers, etc., can solve problems such as insufficient material performance, weakened internal concrete restraint, and core concrete brittleness, etc., and achieves high rigidity. , high strength, the effect of improving frictional energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

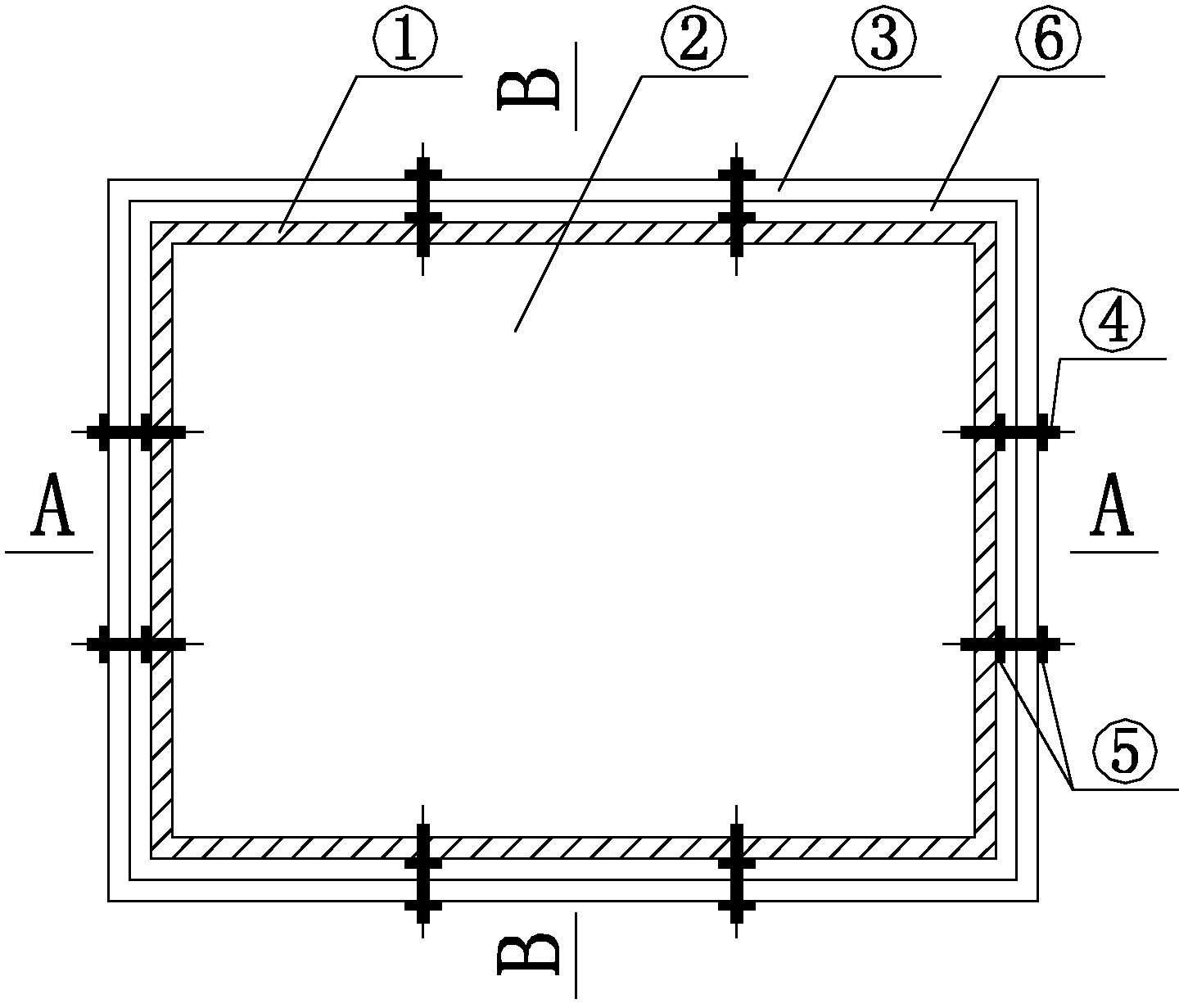

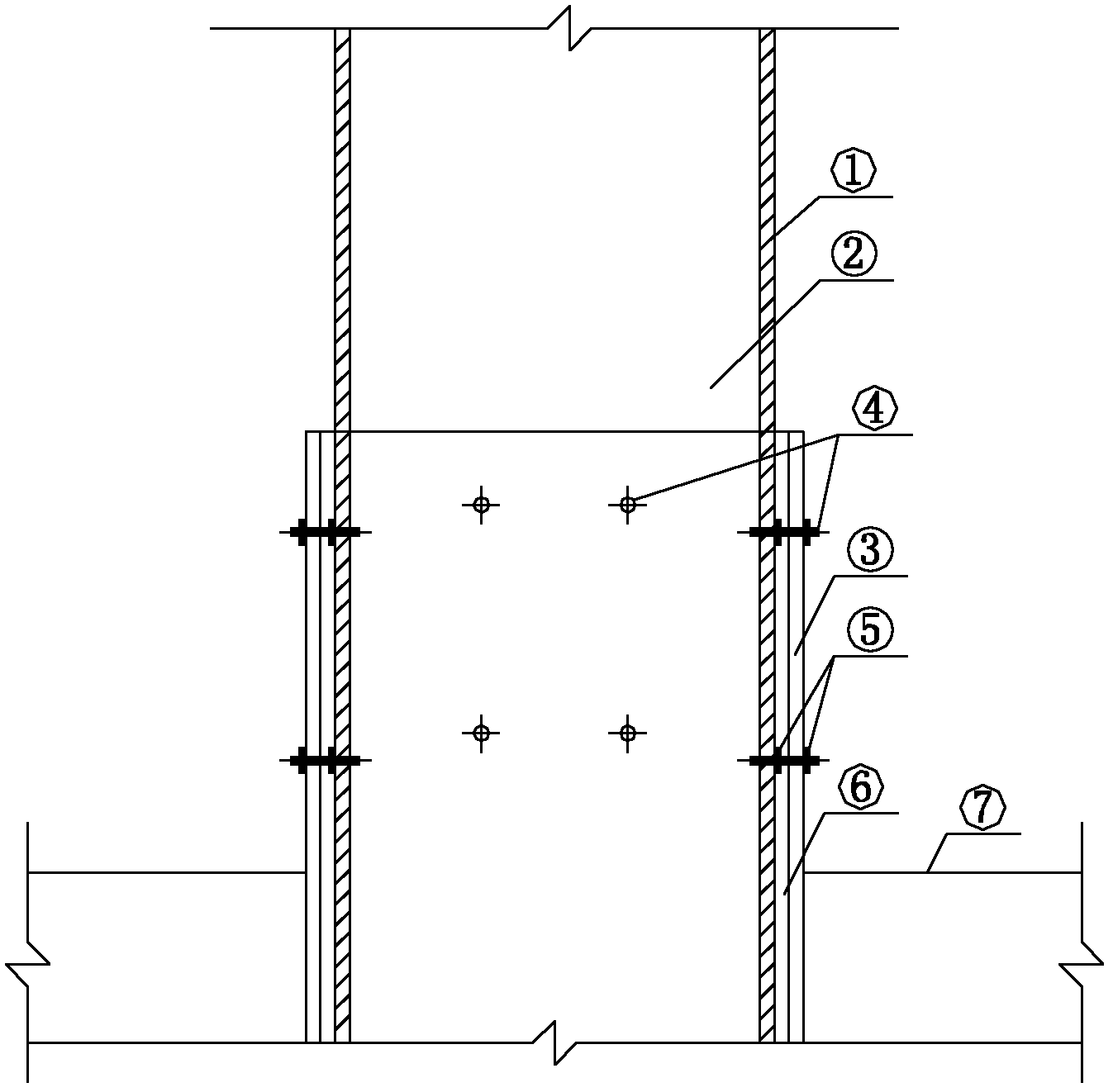

[0049] like figure 1 As shown, the CFST column with a mild steel casing embedded in a high-toughness material at the bottom includes an inner pipe 1, core concrete 2, a mild steel casing 3, bolts 4, and a high-toughness composite material 6. The sectional view of the concrete filled steel pipe column with soft steel casing embedded in high toughness material at the bottom and its method is as follows image 3 and Figure 4 shown. The inner tube 1 is poured with core concrete 2, and the inner or outer side of the bottom wall of the inner tube 1 is sleeved with a mild steel sleeve 3, and the inner tube 1 and the mild steel sleeve 3 are connected and fixed by bolts 4; the inner tube 1 and the mild steel A high-toughness composite material 6 is embedded between the casings 3; the mild steel casing 3 extends into the lower ground or foundation top surface 7 and is anchored thereto. Concrete-filled steel tube columns have a rectangular cross-section. The inner pipe 1 is a rectangu...

Embodiment 2

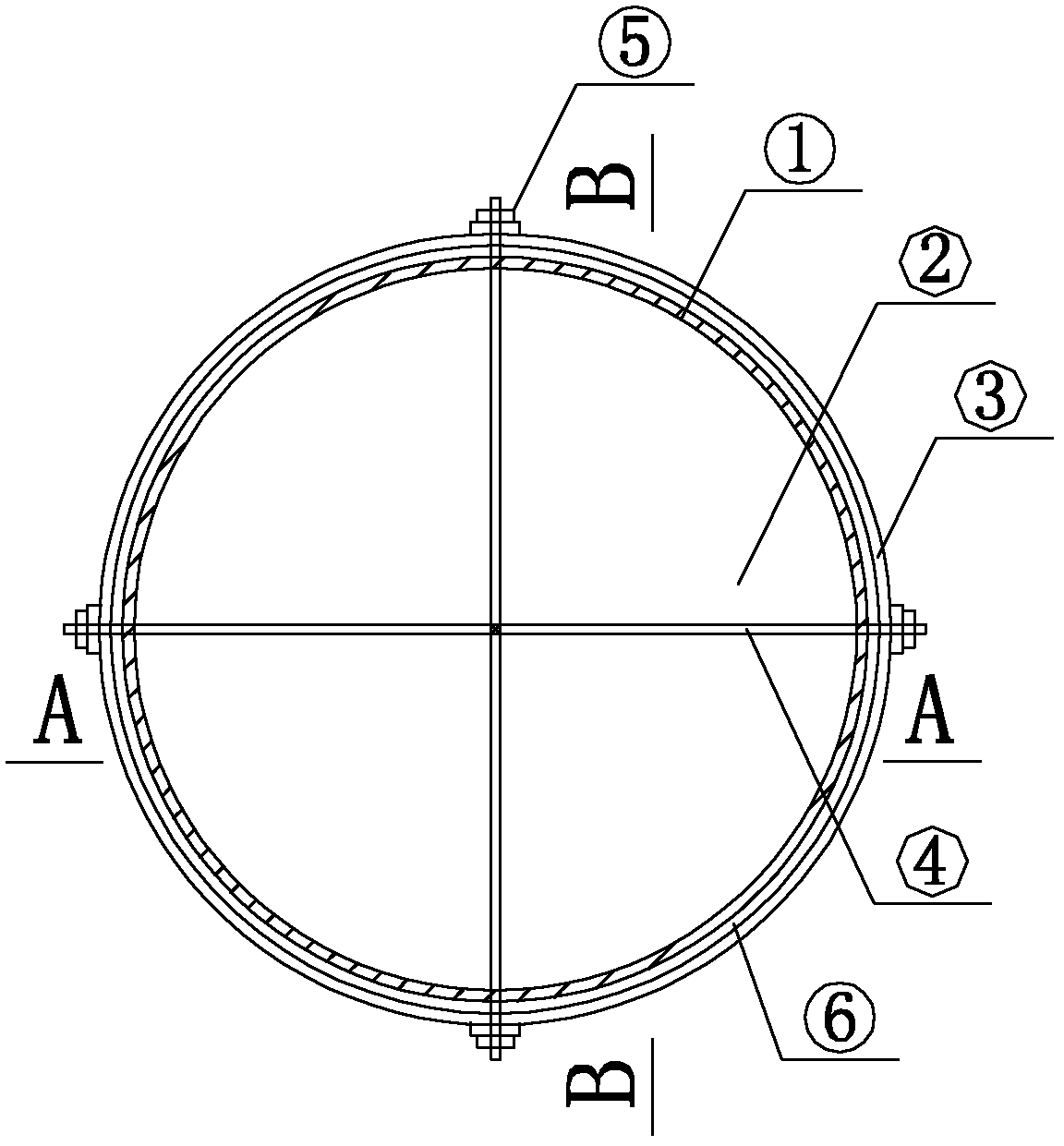

[0056] like figure 2 As shown, the cross-section of the CFST column with a mild steel casing embedded in a high-toughness material is circular, and its cross-section is shown in Figure 5 and Image 6 shown. Its basic principle, anti-seismic performance and manufacturing method are basically the same as those in Embodiment 1.

Embodiment 3

[0058] like Figure 7 As shown, in order to ensure the appearance of the structure on the facade, the mild steel casing 3 of the steel pipe concrete column with a soft steel casing embedded in a high toughness material is placed inside the inner pipe 1, and its cross-sectional view is shown in Figure 9 shown. In this way, from the outside, there is no difference between the steel pipe concrete column with the soft steel casing embedded in the high toughness material and the ordinary steel pipe concrete column, but its seismic performance is obviously better than the ordinary steel pipe concrete column. In this embodiment, the high-toughness composite material should be embedded inside first, and then the concrete should be poured; since the high-toughness composite material is inside the steel tube concrete, the construction technology requirements are relatively high, and the high-toughness composite material can no longer be embedded under the condition of meeting the desig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com