Method for judging pile body uniformity of cement soil stirring pile

A technology of a cement-soil mixing pile and a judging method, which is applied in the field of construction pile foundations, can solve the problems of difficulty in objectively reflecting the uniformity of the pile body, unable to fully reflect the situation, and no index judgment, etc., so as to save testing costs, overcome randomness, Physically meaningful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

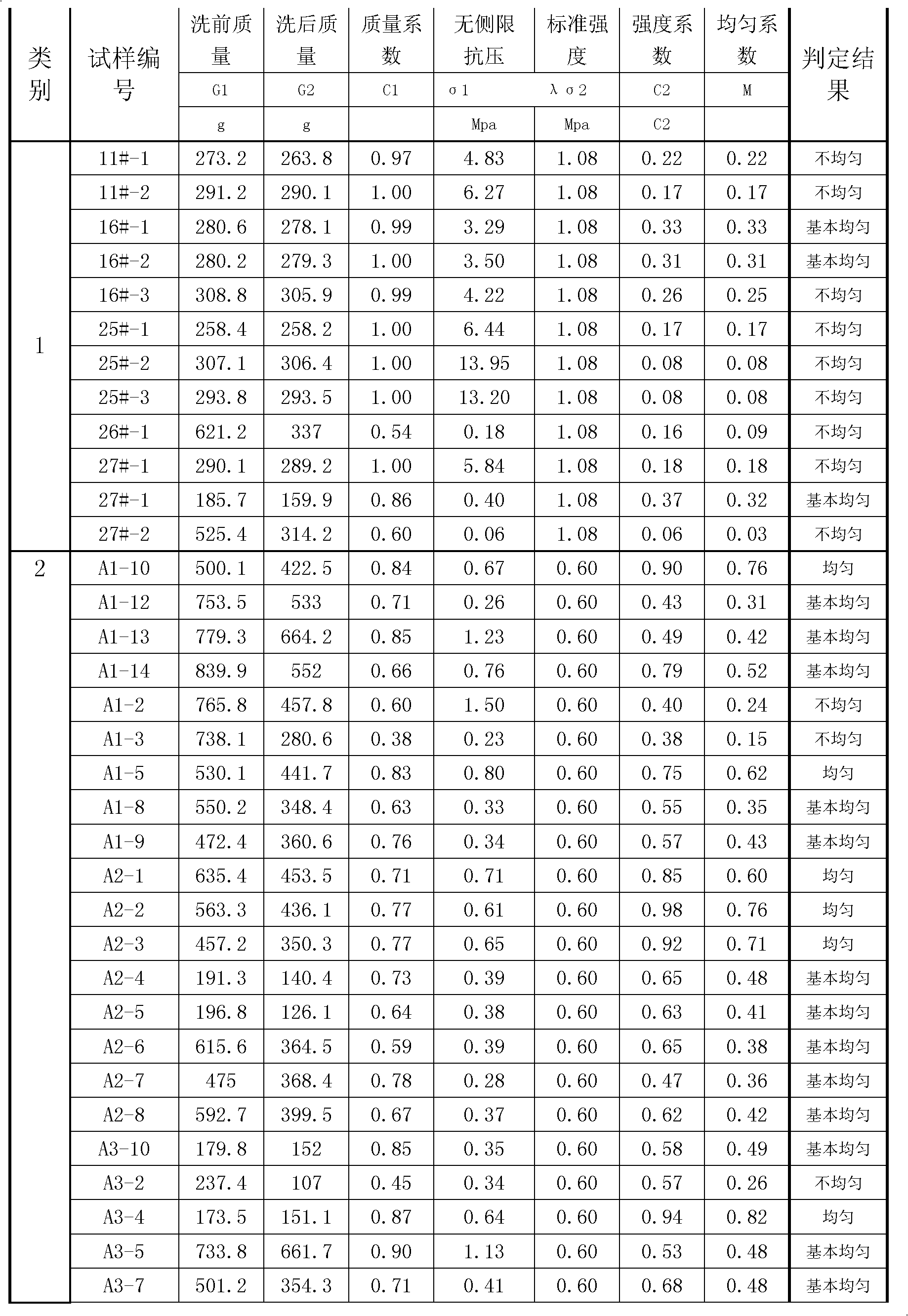

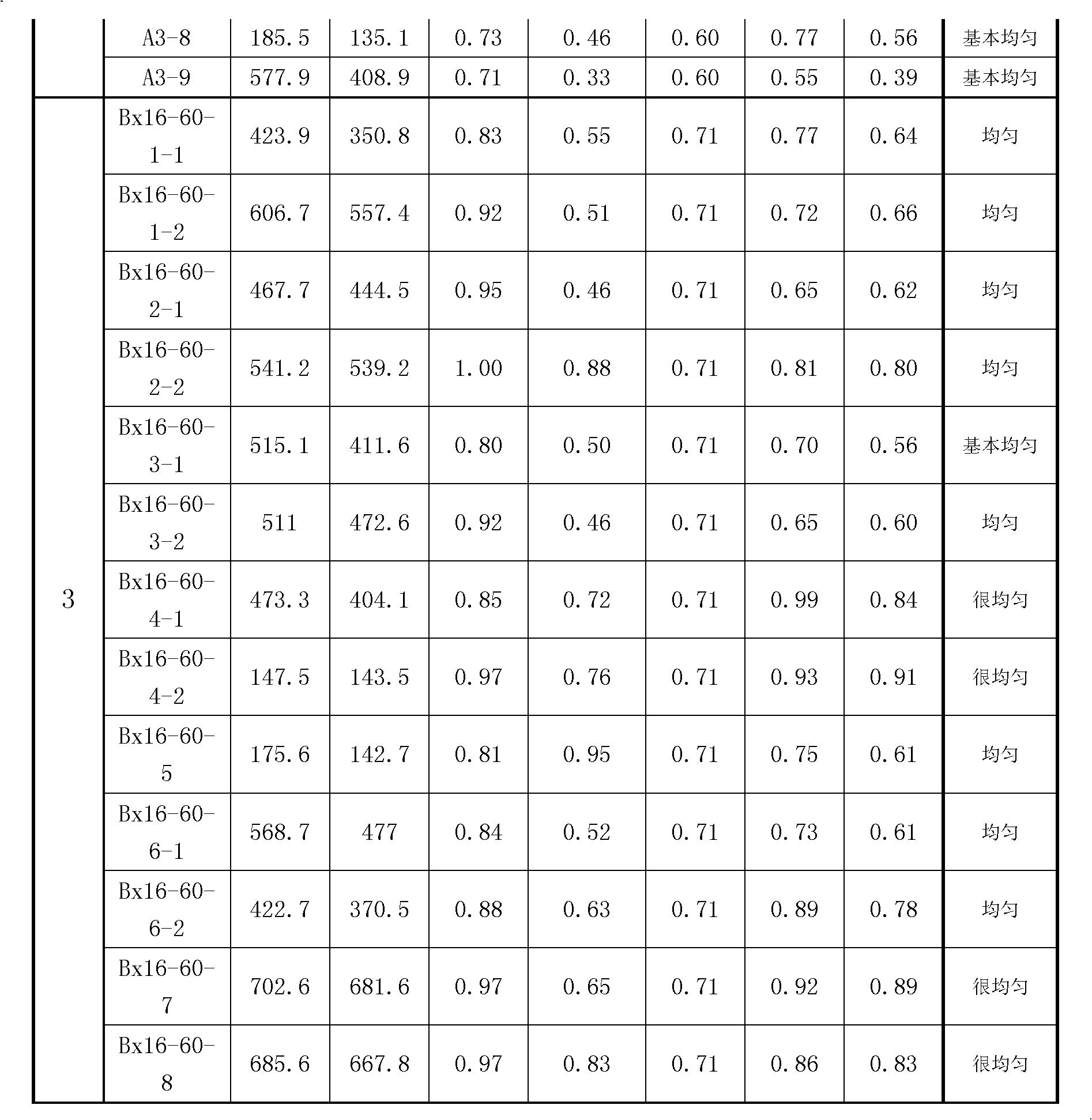

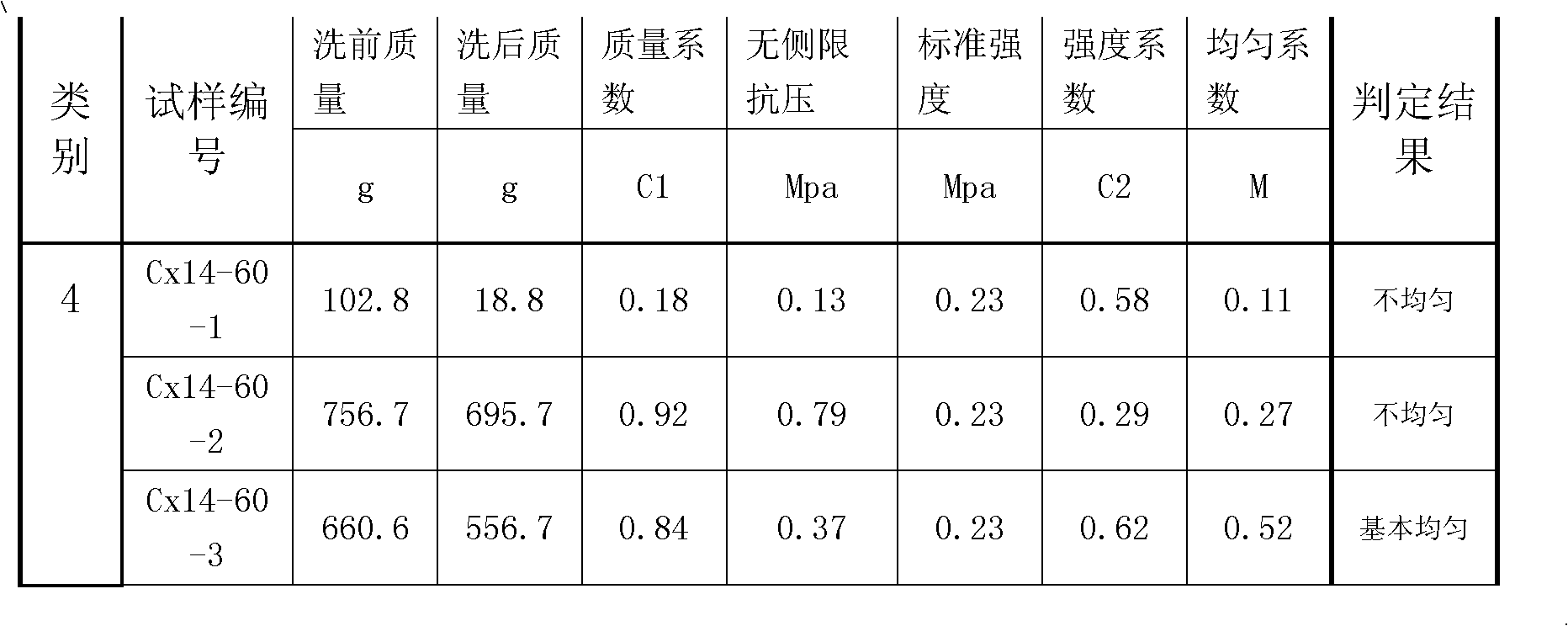

[0049] The method for judging the uniformity of the cement-soil mixing pile pile body of the present invention, its steps are as follows:

[0050] 1. Use a drilling rig to pull the core (diameter not less than 110mm) of cement-soil mixing piles that have reached the core-pulling detection age (the pile-forming age is not less than 28 days), according to a certain distance (1m or 2m, generally not more than 2m) Cut out the core sample (the sample length is not less than 15cm) and seal it;

[0051] 2. In the room, the cement-soil mixing pile core sample taken in the field is prepared in the order of in-situ burial depth (from small to large) into a cylindrical sample with a height-to-diameter ratio of 1:1-1:1.5 (the two ends of the sample The error of the unevenness is not more than 0.05mm, the error of the diameter along the height is not more than 0.3mm, and the deviation of the weight of the end face from the axis is not more than 0.25°);

[0052] 3. Measure the natural unco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com