Thin shell cabin cover die for wind-driven generator and manufacturing method thereof

A wind turbine and nacelle cover technology, which is applied to home appliances, other household appliances, household components, etc., can solve the quality impact of wind turbine thin shell nacelle covers, the heavy workload of repairing flange edges, and the lack of technical level Requirements and other issues, achieve good compactness, high economic and social benefits, and solve the effects of consumables and labor waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

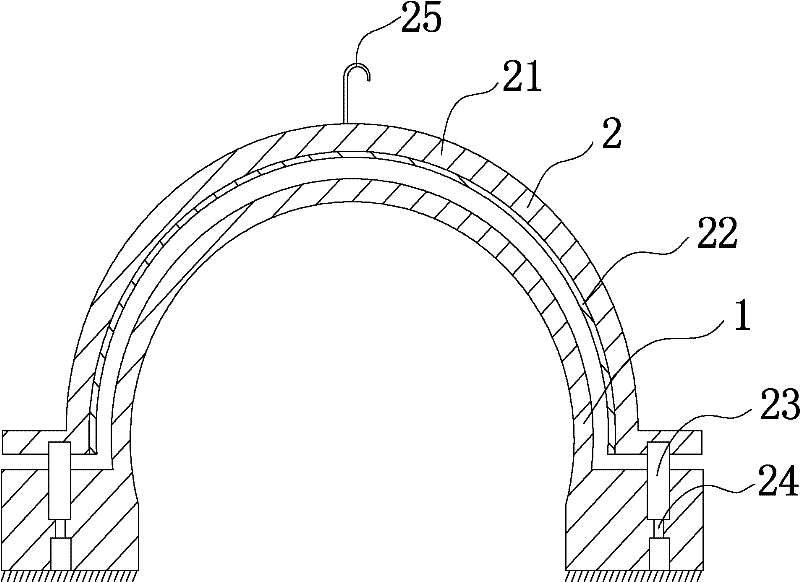

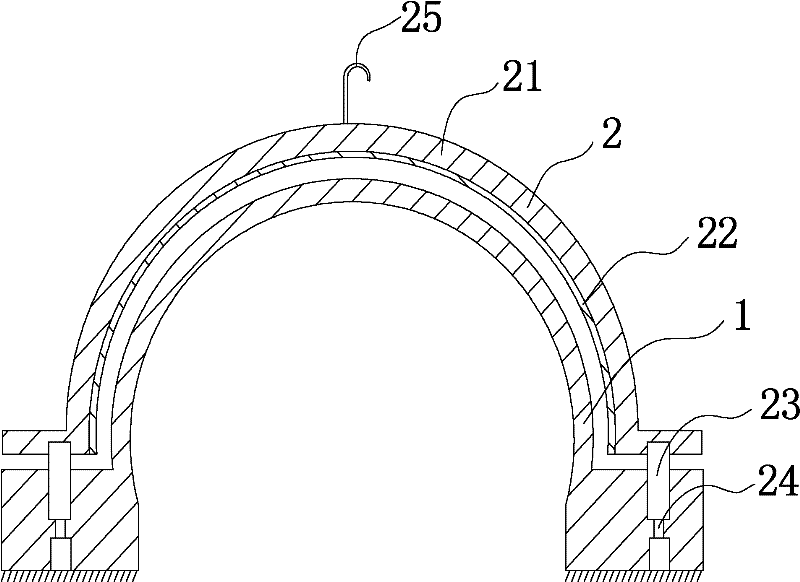

[0015] Such as figure 1 A thin-shell nacelle cover mold for wind power generators shown includes a bottom mold 1 and an upper mold 2, the bottom mold 1 is a convex hard mold, and the upper mold 2 is formed of a concave hard The mold 21 is formed integrally with the soft silicone film 22 coated on its forming surface, and the soft silicone film 22 covers the entire forming surface of the upper mold 2 . . Positioning grooves are arranged on both side edges of the upper mold 2 parallel to the axial direction of the groove, and the positioning grooves face the bottom mold 1, and the bottom mold 1 is provided with a groove corresponding to the above-mentioned positioning grooves. A through hole, a vertical positioning pin 23 is installed in the through hole, and the inner wall of the through hole is attached to the outer surface of the positioning pin 23, the lower end of the positioning pin 23 is fixedly connected with the cylinder 24, and its upper end extends out of the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com