Mechanical atomization nozzle with wide turndown ratio

A technology of mechanical atomization and wide adjustment, applied in the direction of spray device, spray device, etc., can solve the problems of poor atomization effect of atomizing nozzle, unable to meet the requirements of on-site working conditions, etc., to achieve wide practicability, simple structure, operation reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

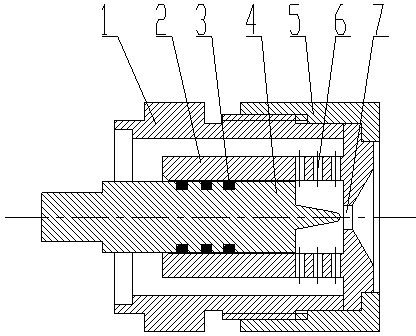

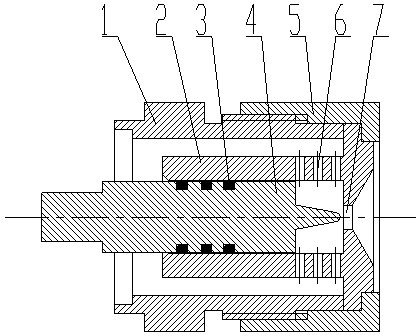

[0010] Such as figure 1 As shown, the wide adjustment ratio mechanical atomizing nozzle of the present invention is mainly composed of a connecting sleeve 1, a multi-layer tangential swirl groove type swirl atomization sheet 2, and an adjusting needle 4. The atomizing sheet 2 is in the shape of a T-tube, and it is set in the cylindrical connecting sleeve 1. 4. The regulating needle 4 is provided with three sealing rings 3 matched with the multi-layer tangential swirl groove type swirl atomizer sheet 2, and the outer end of the multilayer tangential swirl groove type swirl atomizer sheet 2 is provided with It is fastened to the connecting sleeve 1 and the big nut 5, and the multi-layer tangential swirl groove type swirl atomizing sheet 2 is provided with multi-layer tangential swirl grooves on the front outer peripheral wall matched with the adjustment 4 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com