Sine duplex lap winding for synchronous generator

A technology of synchronous generators and stacked windings, which is applied in the field of AC motor windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

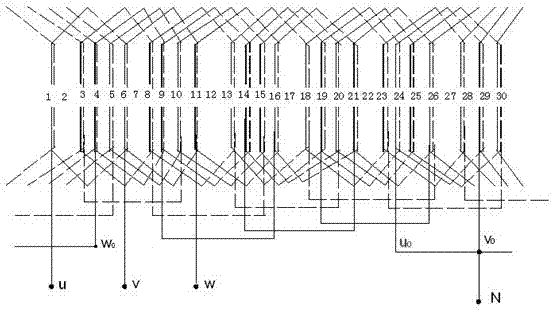

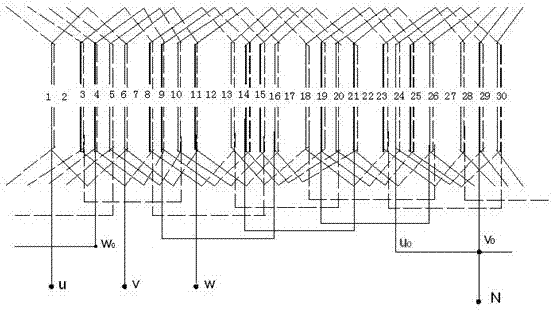

[0013] Such as figure 1 As shown, the number of stator slots of the motor is 30 slots, and the number of poles is 4 poles and 3 phase synchronous generator.

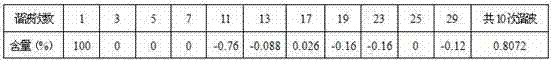

[0014] figure 1 Among the 30 slots, there are 6 empty slots, and there are no coils in these 6 empty slots. These empty slots are evenly distributed, and there are 4 slots between the empty slots. These 6 empty slots are 2, 7, 12, The 6 slots of 17, 22, and 27, and the remaining 24 slots are assigned the slot phases of the three-phase winding according to the number of slots per pole and each phase is 2. The method is a conventional method, that is, the upper layer of the coil is divided into aa, zz, bb, xx , cc, yy arrange the phases, the number of turns of each coil is equal, the pitch of each coil is also equal, and the pitch is 5, so that the lower layer of each slot is also regularly determined according to the upper layer, except for 6 Empty slots, the remaining 24 slots are double-stacked double-layer structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com