Cable connector component

A cable connector and assembly technology, which is applied in the direction of connection, parts of connecting devices, protective grounding/shielding devices of connecting parts, etc. problem, the effect of achieving high data transfer rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

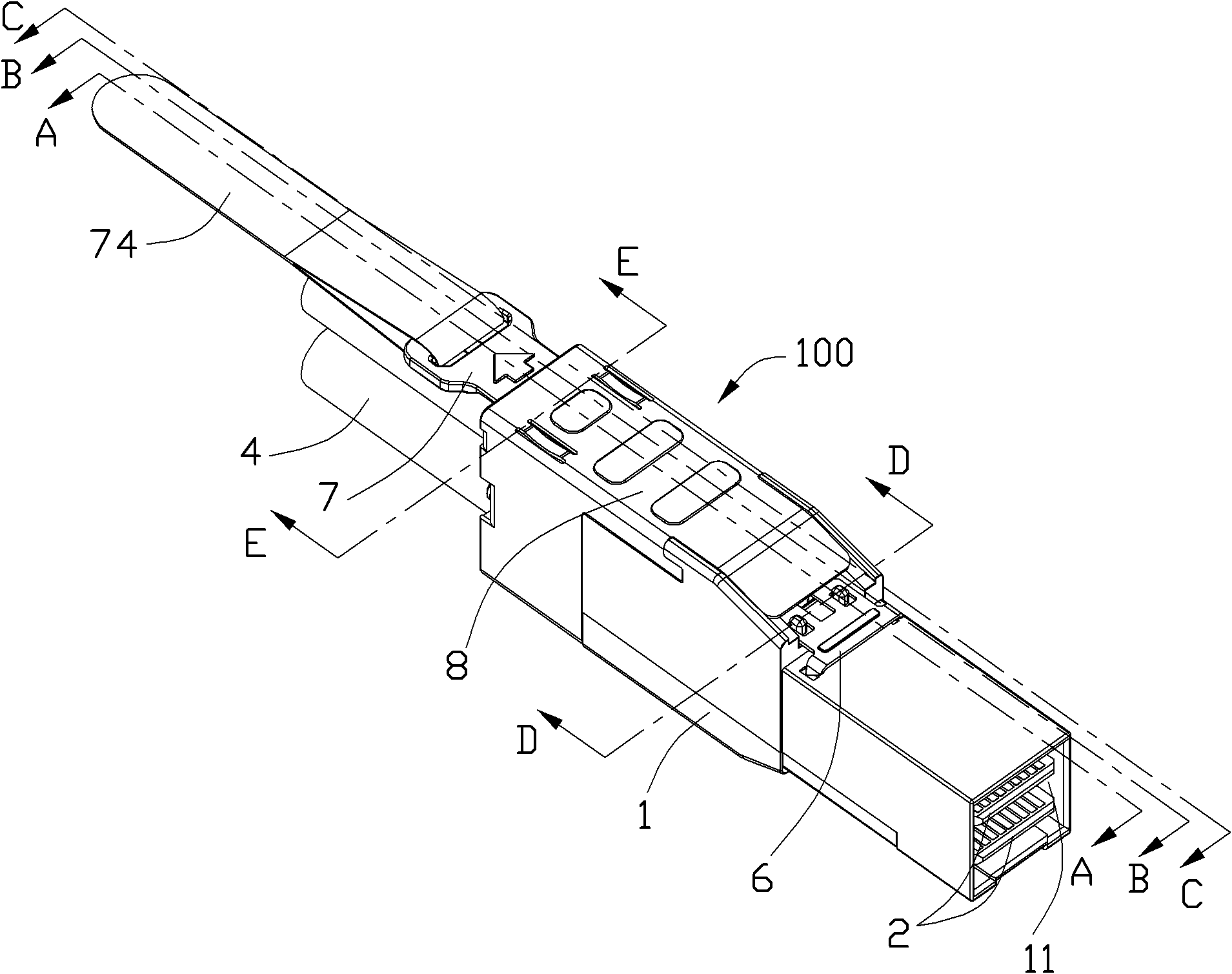

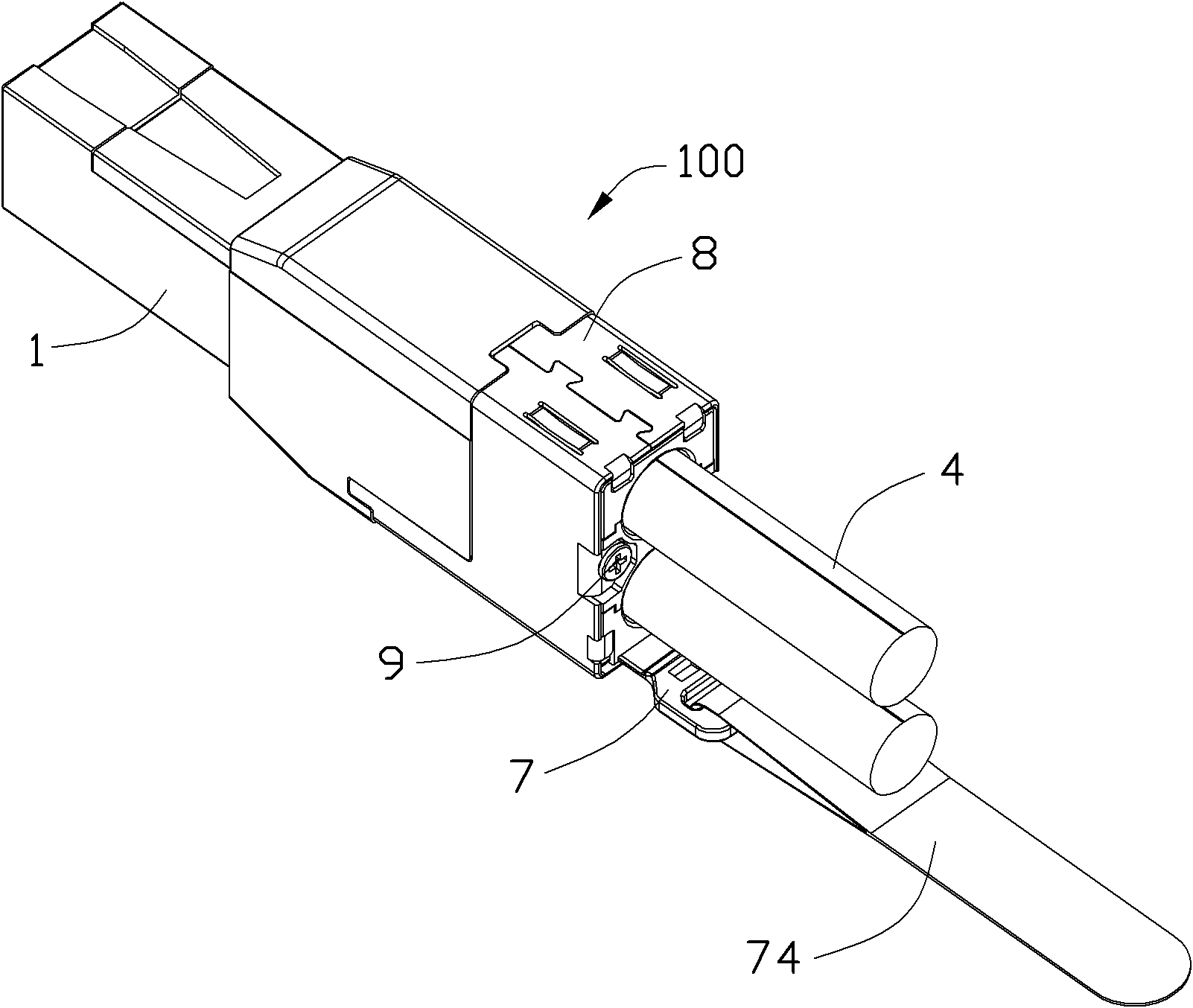

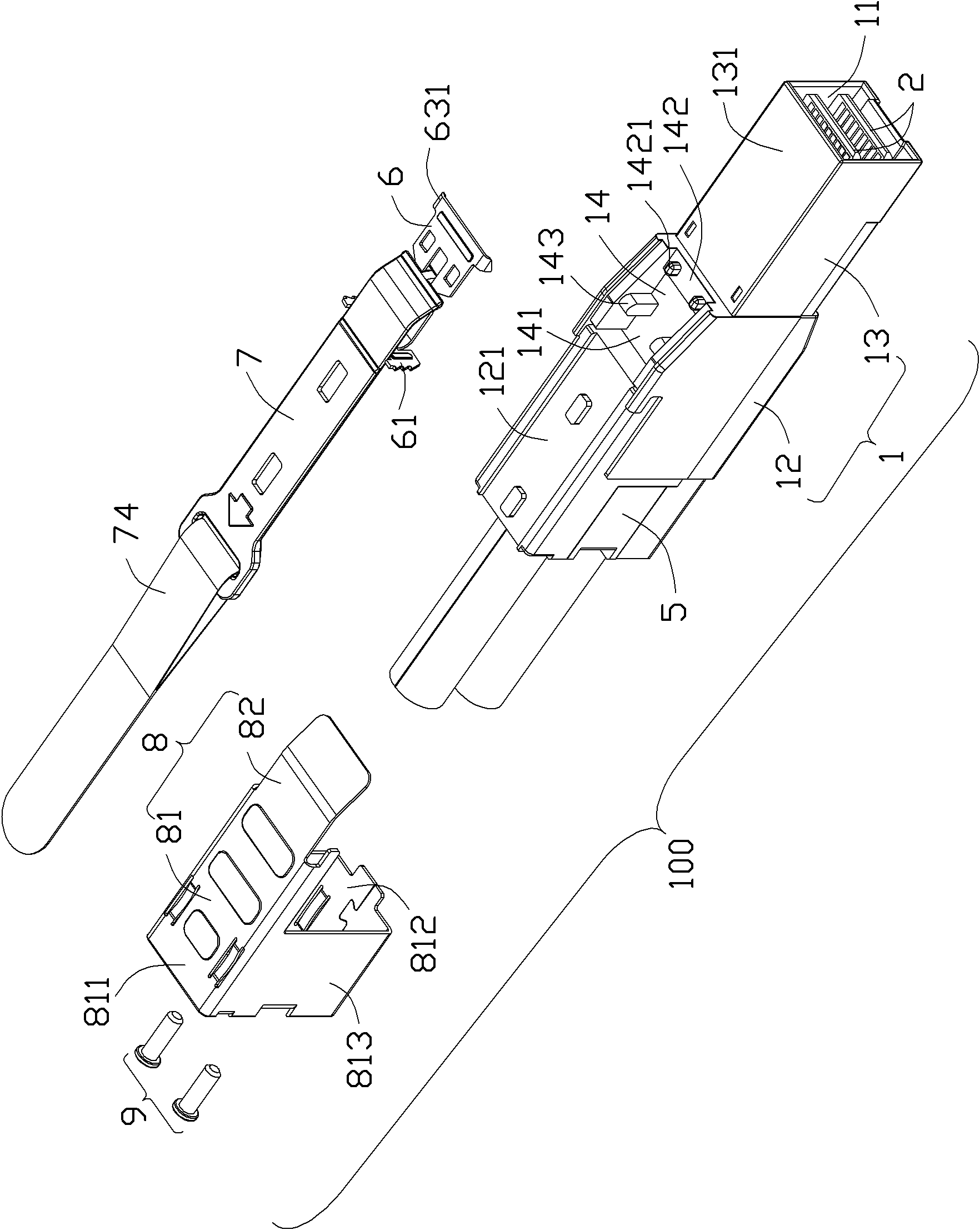

[0018] See Figure 1 to Figure 4 And combine Picture 9 , The cable connector assembly 100 of the present invention includes a main body 1 having a receiving space 11, two printed circuit boards arranged in parallel and spaced apart in the receiving space 11, and arranged between the two printed circuit boards 2 and connected to the main body 1 The partitions that are positioned and matched with each other 3, the two cables 4 that are electrically connected to the rear ends of a pair of printed circuit boards 2 and extend back out of the body 1, are assembled in the body 1 and separate the two cables 4 Coming out of the stress relief block 5. In addition, the cable connector assembly 100 also includes a locking member 6 provided on the upper surface of the body 1, a drawing member 7 provided on the upper surface of the body 1 and connected with the locking member 6, and a drawing member 7 surrounding the outer surface of the body 1. Metal shield 8.

[0019] See Figure 3 to Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com