Dual-ring sealing device at gas compressor end of turbocharger

A technology of turbocharger and sealing device, applied in the direction of machine/engine, parts of pumping device for elastic fluid, mechanical equipment, etc., can solve the problem of oil leakage, poor oil return, and high oil level in crankcase problem, to prevent leakage and increase the reliability of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

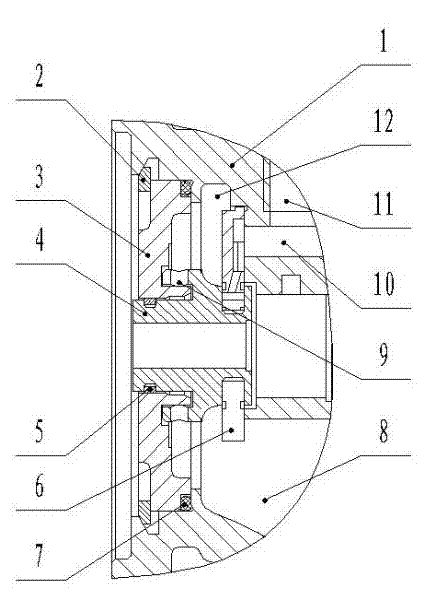

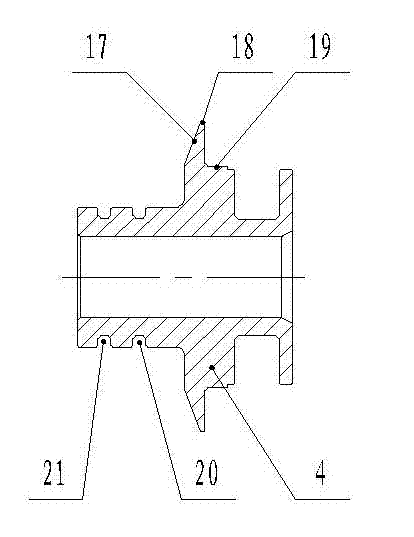

[0059] Examples such as figure 2 As shown, a double-ring sealing device at the compressor end of a turbocharger includes a middle shell 1, a thrust oil throwing pan 4 is arranged inside the middle shell 1, and a sealing ring is arranged between the thrust oil throwing pan 4 and the middle shell 1 The sleeve seat 3 and the seal ring sleeve seat 3 are set on the front end of the thrust oil throwing pan 4 and are sealed and rotationally connected with the thrust thrust oil throwing pan 4 .

[0060] There is a certain gap between the thrust oil throwing pan 4 and the sealing ring housing 3, and two sealing devices are arranged in the gap, and the gap between the two sealing devices forms a low-pressure chamber.

[0061] The middle shell 1 and the sealing ring seat 3 are sealed and connected with the elastic circlip 2 and the O-ring 7 through the hole.

[0062] Each sealing device includes a sealing ring 5 arranged between the thrust throwing oil pan 4 and the sealing ring seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com