Vortex Compressor

A scroll compressor and compression mechanism technology, applied in the field of scroll compressors, can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

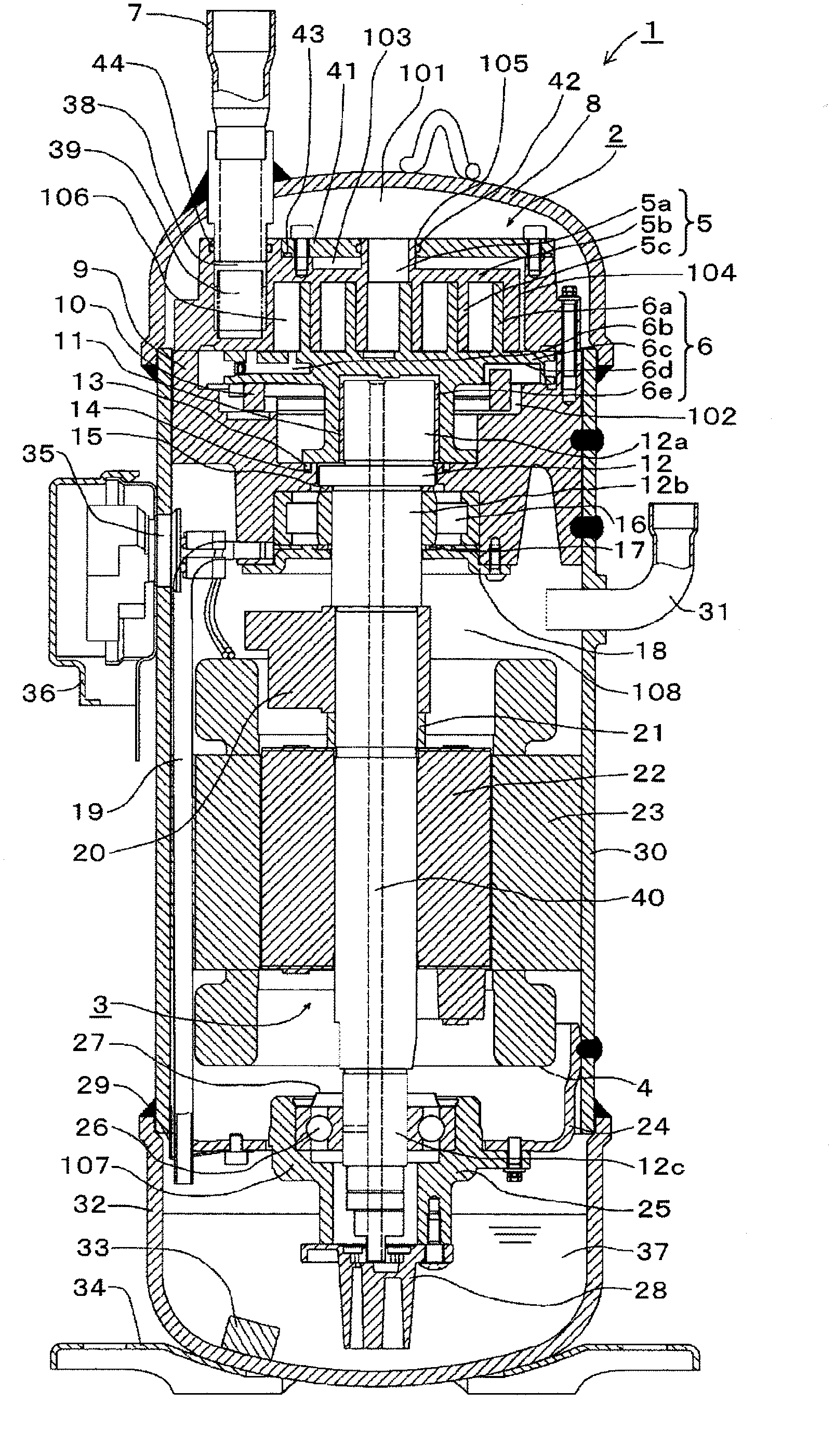

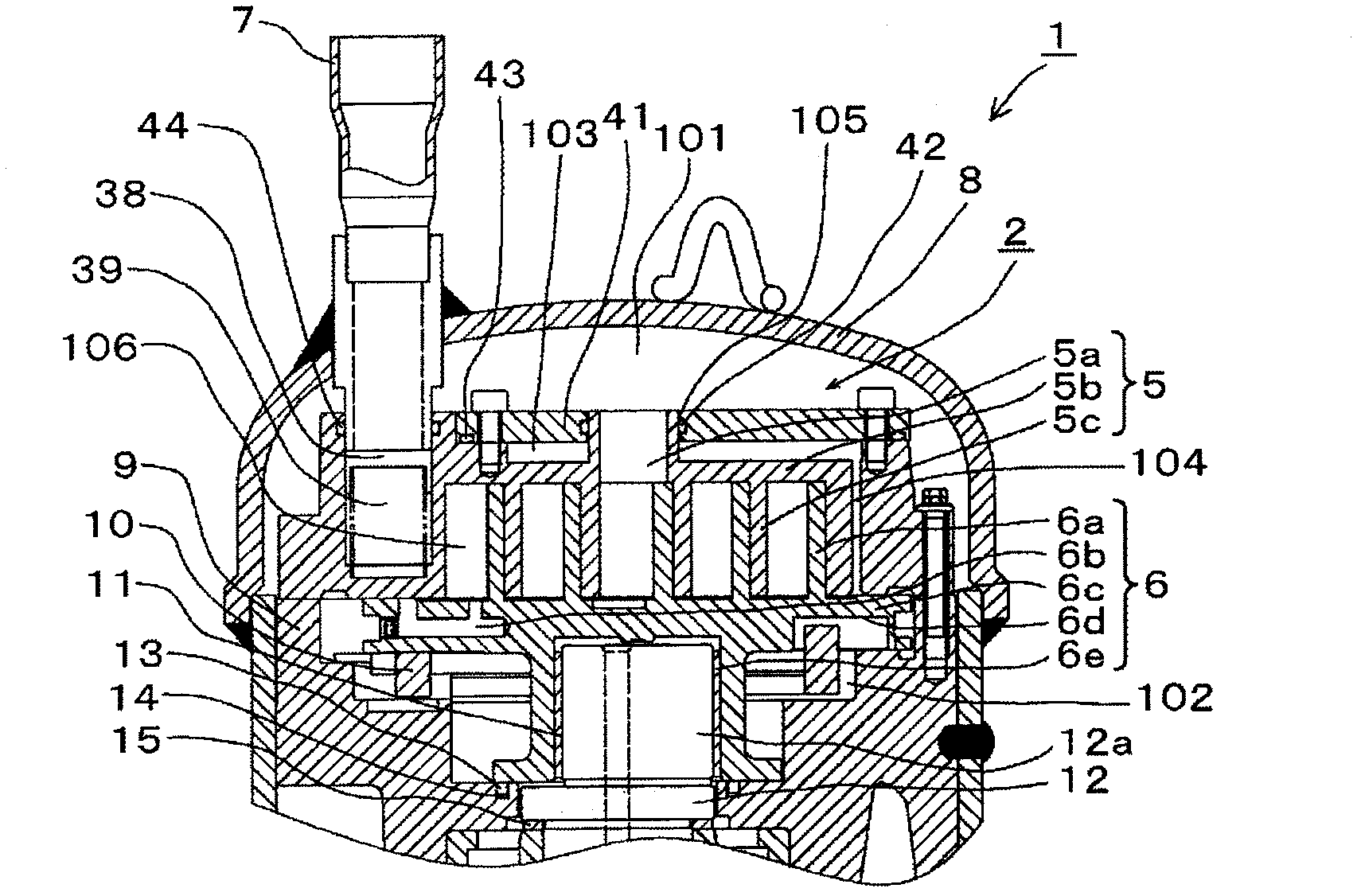

[0071] use figure 1 and figure 2 A scroll compressor according to a first embodiment of the present invention will be described.

[0072] figure 1 is a longitudinal sectional view of a scroll compressor according to a first embodiment of the present invention, figure 2 yes figure 1 Enlarged view of the compression mechanism.

[0073] The scroll compressor 1 is configured by accommodating a compression mechanism unit 2 , a drive unit 3 , and a rotating shaft 12 in an airtight container 30 . In this embodiment, a vertical scroll compressor in which the compression mechanism part 2 is arranged above and the drive part 3 is arranged below is a so-called high-pressure chamber type compressor.

[0074] The compression mechanism unit 2 is configured with a fixed scroll 5 , an orbiting scroll 6 , and a frame 9 as basic components. The frame 9 is fixed to the airtight container 30 and constitutes a member in which the rolling bearing 16 is arranged. The fixed scroll 5 has a sc...

Embodiment 2

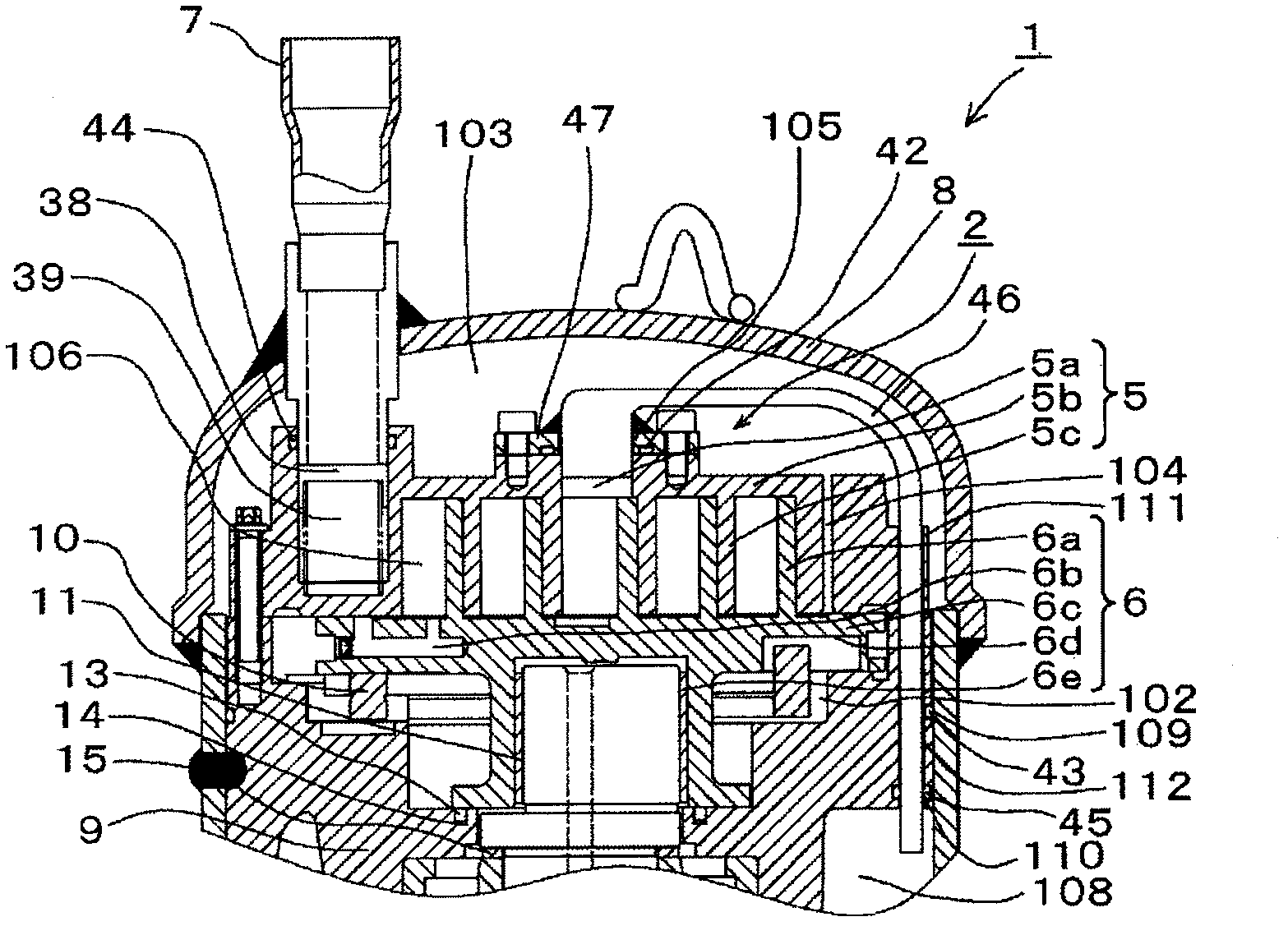

[0096] use image 3 A scroll compressor according to a second embodiment of the present invention will be described.

[0097] Use the space between the fixed scroll top plate 5b and the upper cover 8 as the top plate chamber 103, use the discharge flange 47 to fit one end of the discharge gas guide pipe 46 into the fixed scroll discharge port 5a, and make the discharge gas guide pipe The other end of 46 is guided to the motor upper space 108 through the through holes 111 and 112 provided in the fixed scroll 5 and the frame 9 , so that the fixed scroll discharge port 5 a communicates with the motor upper space 108 . Here, the outer diameter of the frame 9 and the inner wall of the airtight container 30 and the discharge gas guide pipe 46 and the through-hole 112 of the frame 9 are fitted with the sealing members 43 and 45 so that the ceiling chamber 103 does not communicate with the upper space 108 of the motor. combine. Furthermore, the orbiting scroll back pressure chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com