Methanol flowing feeding on-line disinfection method and automatic control system

A disinfection method and methanol technology, applied in the field of fermentation, can solve problems such as unseen facilities and solutions, and achieve the effect of high use value, strong pertinence and clear processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

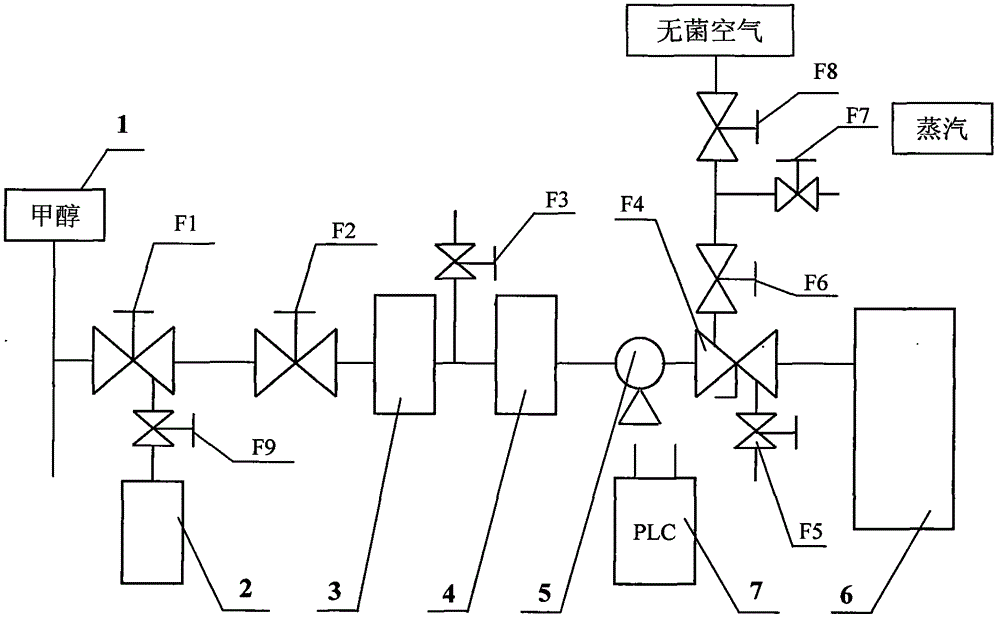

[0027] As shown in the drawings, the present invention includes several control valves, a methanol tank 1, a water storage tank 2, a methanol pre-filter 3, a methanol sterilization filter 4, a peristaltic pump 5, a fermenter 6, a peristaltic pump control component 7, etc. Control valve F1, control valve F2, methanol pre-filter 3, methanol sterilization 4, peristaltic pump 5, control valve F4 are sequentially connected between methanol tank 1 and fermenter 6; the control valve F1 is also passed through the control valve F9 is connected to the water storage tank 2, a branch is set between the methanol pre-filter 3 and the methanol sterilization filter 4 to connect the control valve F3, the control valve F4 is also connected to the control valve F5, and passes through the control valve F6 The control valve F7 and the control valve F8 are connected, and the peristaltic pump 5 is connected with the automatic control part 7 .

[0028] The control components include transmitters, PLC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com