Outgoing line managing device for power construction

A management device, power construction technology, applied in thin material handling, transportation and packaging, equipment for dismantling/armoring cables, etc. Easy to operate, improve production efficiency, and standardize the effect of management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

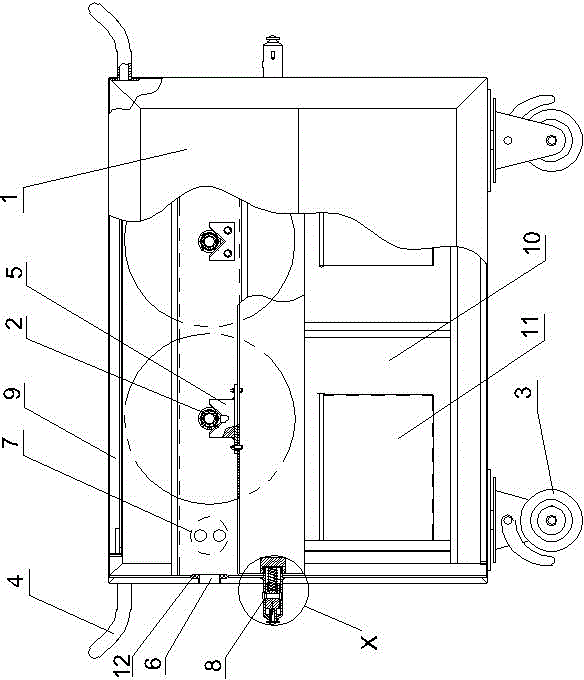

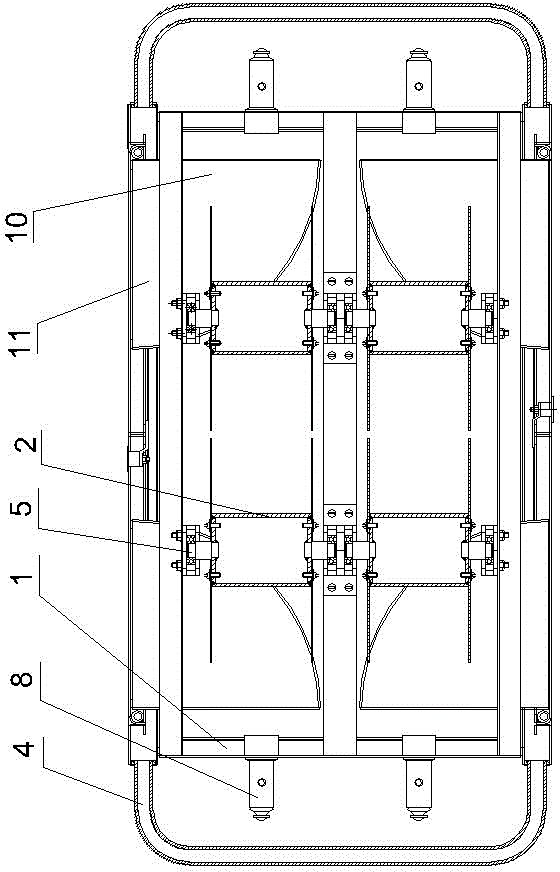

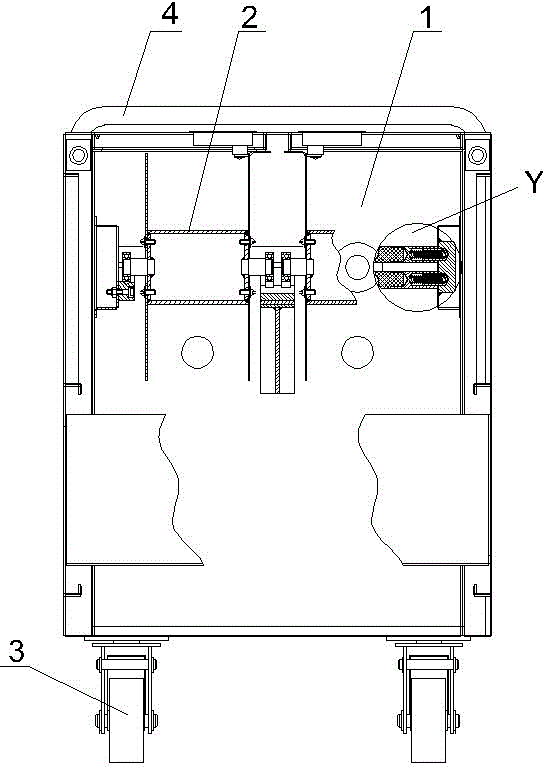

[0017] Such as figure 1 , figure 2 and image 3 As shown, the outlet management device for electric power construction according to the present invention has a box body 1 and a bobbin 2, brake wheels 3 are installed at the four corners of the lower end of the box body 1, and push handles 4 are respectively provided at the front and rear ends of the upper part of the box body 1 There are four bobbins 2 in two rows and two rows in the box body 1, and the bearings at both ends of the bobbin 2 are supported on the quick-installed bearing housing 5. The front and rear wall panels of the box body 1 are provided with outlet holes 6, and the outlet holes 6 and A cable guide mechanism 7 is provided between the bobbins 2, a wire end locking mechanism 8 is provided on the front and rear wall panels of the box body 1 below the outlet hole 6, and a top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com