EEPROM on-line burner and on-line burning method

A programming method and technology of programming instrument, which are applied in the fields of instruments, information storage, static memory, etc., can solve the problems of crooked IC pins, complicated programs, and high loss rate of programming data, so as to avoid crooked IC pins. , Save the burning program, avoid the effect of high loss ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

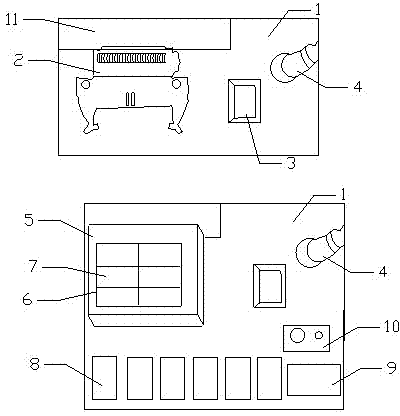

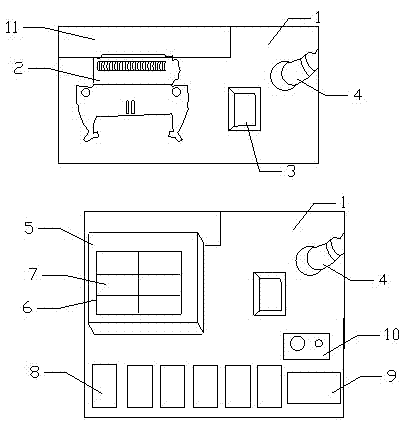

[0020] figure 1 As a preferred embodiment of the present invention, the present invention will be further described below in conjunction with the accompanying drawings, wherein, 1 programmer, 2 data cable connector, 3 power switch, 4 DC socket, 5 clamp, 6 PCBA, 7 blank IC, 8 IC seat, 9 display interface, 10 operation button, 11 signal connection port.

[0021] according to figure 1 , EEPROM online burner, characterized by: including burner 1 and a jig for installing PCBA6; burner 1 is connected to the jig, and PCBA6 is soldered with a blank IC7; burner 1 is provided with an IC for placing the mother chip IC seat 8. The present invention realizes the data connection between the blank IC7 on the PCBA6 and the mother chip IC placed on the programmer 1 through the connection between the programmer 1 and the jig, so as to complete the programming, comparison and reading of the blank IC7 described later. The jig includes a PCBA6 and a jig 5 holding the PCBA6, and the jig 5 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com