Garbage salvage ship

A technology for salvaging ships and garbage, which is applied in the cleaning of special-purpose ships, open water surfaces, ships, etc. It can solve the problems of clogged sludge pumps, thickened sludge, and low cleaning efficiency, and achieves low investment, small ship size, and easy production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings.

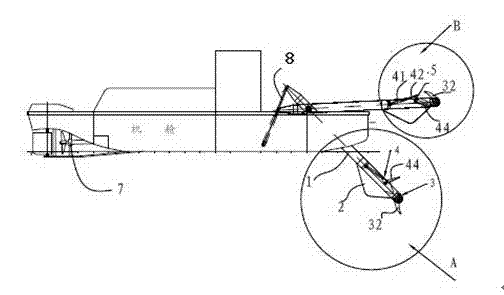

[0027] Such as figure 1 As shown, the garbage salvage ship includes a propeller 7 located at the stern of the ship, a diesel-driven oil pump located in the engine room of the hull, and a garbage collection mechanism located at the bow of the ship. The garbage collection mechanism includes a garbage hopper frame 1 and garbage under the garbage hopper frame 1. Bucket 2, a knife fishing mechanism 3 located at the front end of the garbage hopper frame 1, and a scraper mechanism 4 located on the garbage hopper frame 1. The knife fishing mechanism 3 includes a small sprocket 31, a first cylinder 33, a linkage mechanism 5 and a small sprocket hinged The arc-shaped fishing knife 32 on 31, the scraper mechanism 4 includes a second oil cylinder 41, a large sprocket 42, a link mechanism 5, and a scraper 44 which are hinged to each other in sequence, and a third oil cylinder 8 is hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com