High-flow flushing device

A flushing device and high-flow technology, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of long flushing time period and secondary pollution of system pipelines, shorten flushing time, and ensure flushing quality, improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

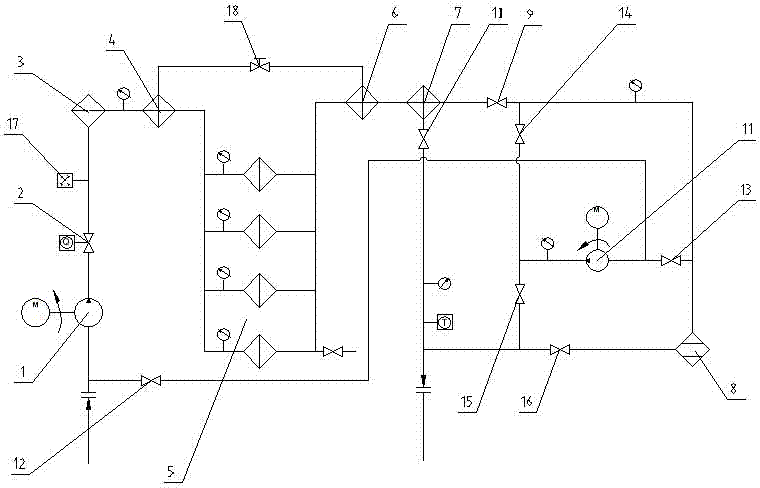

[0014] The present invention will be further described below in conjunction with accompanying drawing. As shown in the figure, a large-flow flushing device includes a main oil pump 1, a flow control valve 2, a coarse filter 3, a first heater 4, and a filter composed of four filters connected in sequence through the main oil pipeline. group 5, second heater 6, third heater 7 and fine filter 8; a first valve 9 is provided between the third heater 7 and the fine filter 8, and there is a The pipeline provided with the second valve 10 leads to the oil outlet; an auxiliary oil pipeline with an auxiliary oil pump 11 is connected in parallel at both ends of the main oil pipeline, and the auxiliary oil pipeline is located on the oil inlet of the auxiliary oil pump 11. There is a third valve 12 at the position between the port and the oil inlet of the main oil circuit, and the pipes with the fourth valve 13 and the fifth valve 14 are respectively provided on the pipelines of the oil inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com