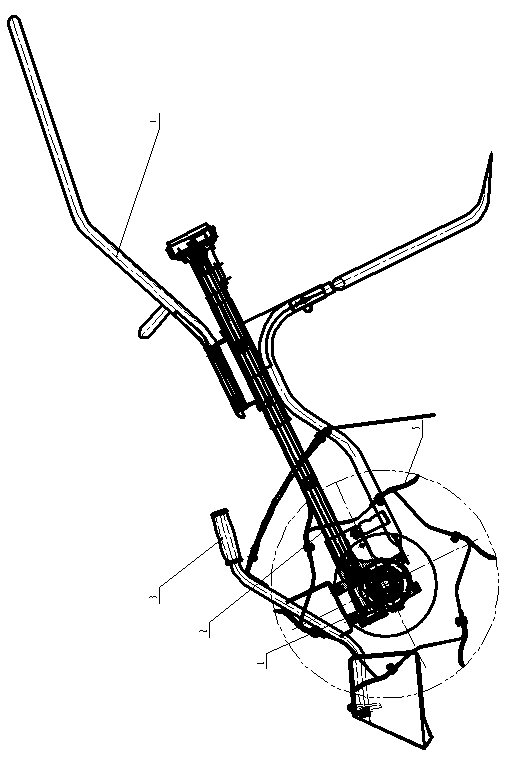

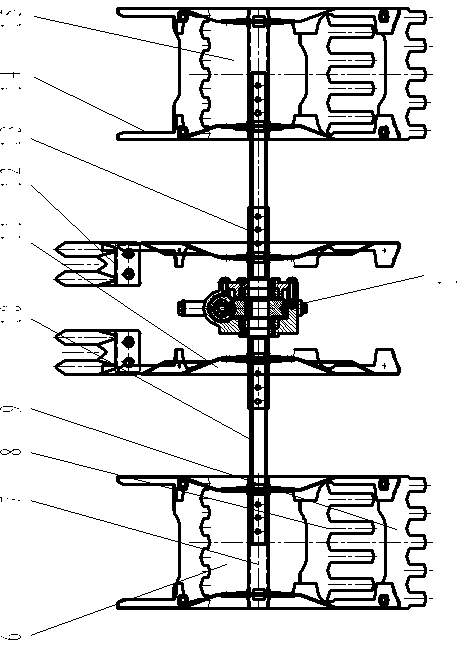

Three-row weeder tilling wheel component

A technology of weeding machines and parts, which is applied in the fields of tillage machines, agricultural machinery and implements, etc. It can solve the problems of missing tillage and removal between tooth gaps, narrow backs of teeth for loosening soil, missing tillage and removal, etc., so as to improve operating efficiency , the total power is reduced, and the effect of increasing the tillage wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

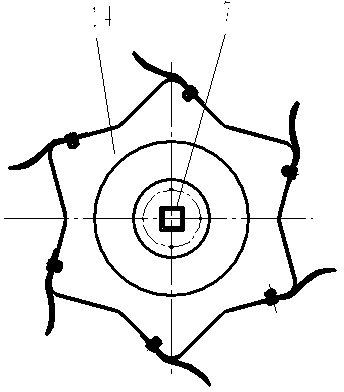

[0018] Tilling wheel 6,15 is made of left and right two wheel hubs 14, three five-tooth loosening teeth 9, three four-tooth loosening teeth 9 and square casing 7. The two ends of the loosening teeth are connected between the left and right two wheel hubs 14, the five-tooth loosening teeth 9 and the four-tooth loosening teeth 8 are evenly spaced, and the tooth tips and tooth gaps of adjacent loosening teeth are interlaced with each other. Both ends of the sleeve 7 pass through and are fixed at the centers of the left and right hubs 14 . The distance between the left and right two hubs 14 of the tillage wheel is equal to the row spacing of crops. The five-tooth loosening tooth 9 and the three four-tooth loosening teeth 9 adopt 65Mn steel, and the tooth back width B is 36 to 42 millimeters.

[0019] The semi-tillage wheel is composed of a wheel hub 11, six two-tooth loosening teeth 12 and a square casing 13, and the six two-tooth loosening teeth 12 are evenly arranged along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com