Protective device for electrical system box vent hole

A technology for electrical systems and protective devices, which is applied to the cooling/ventilation of substation/distribution device enclosures, electrical components, and substations/switchgear. Not good and other problems, to achieve the effect of good ventilation, firm fixation, and increased ventilation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

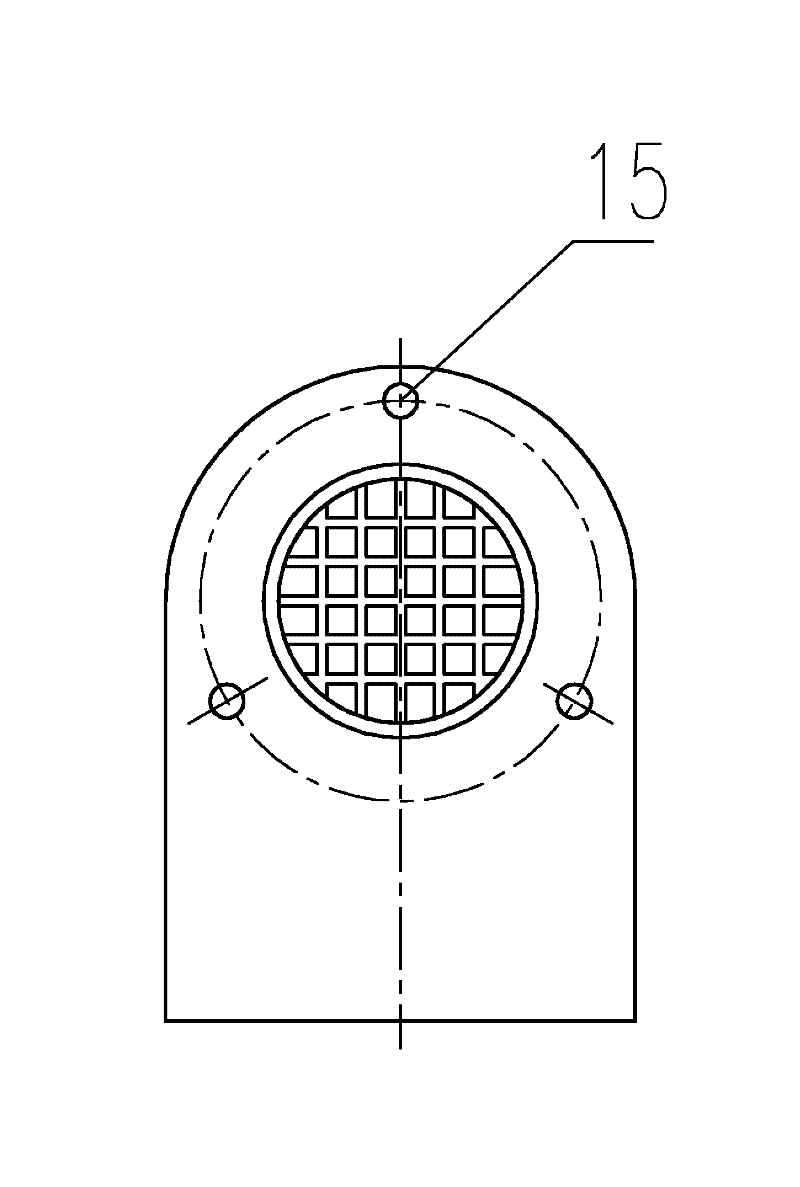

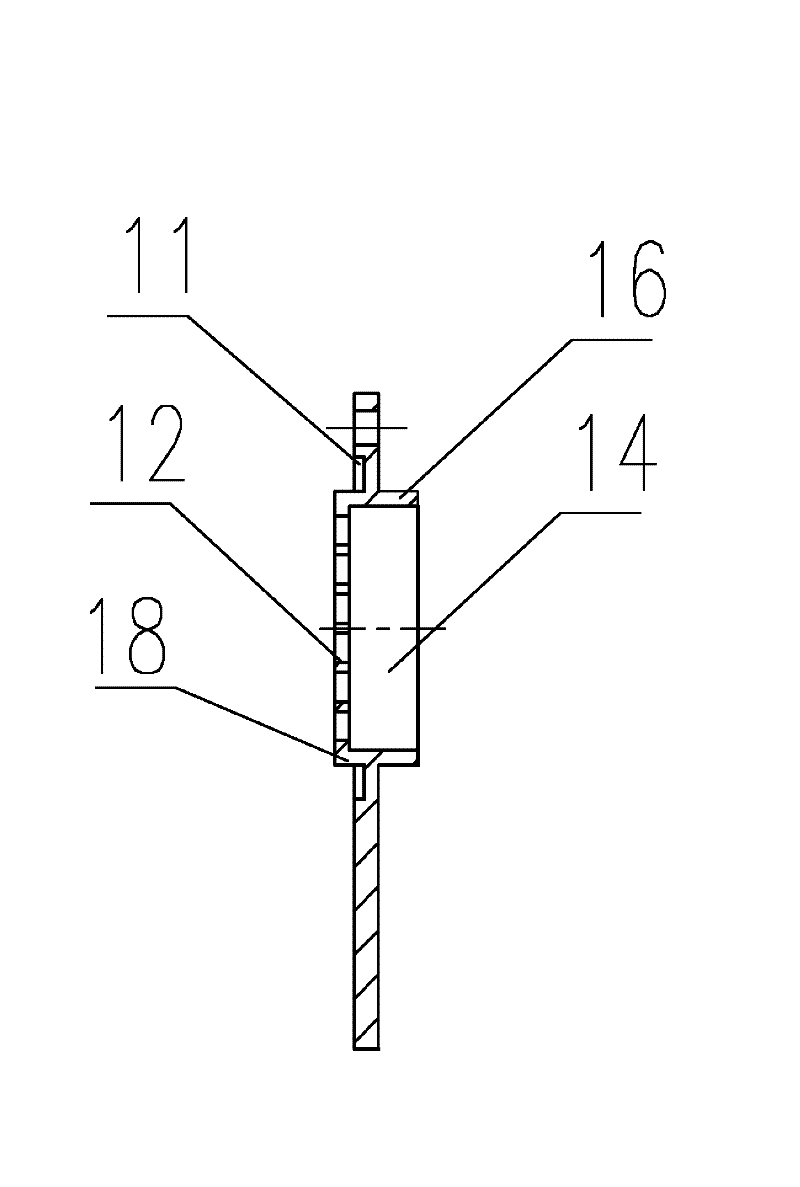

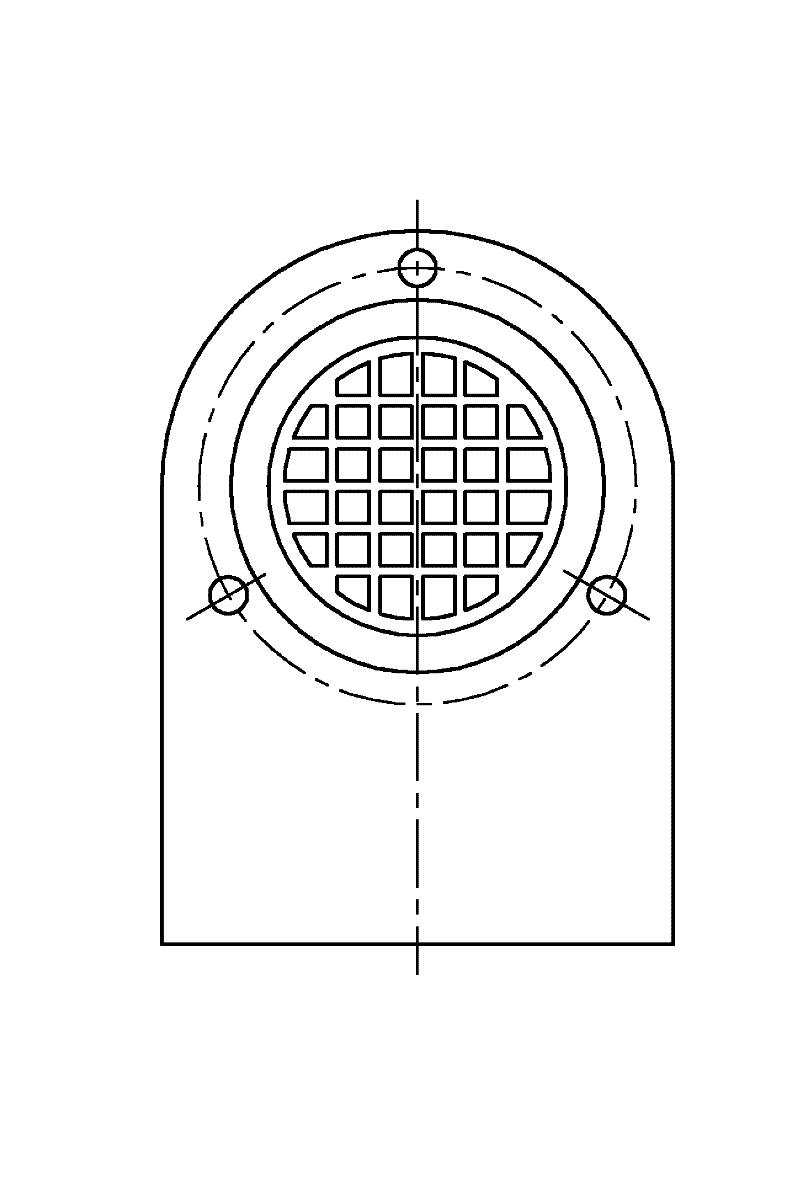

[0032] Embodiment 1 of a protective device for ventilation holes of an electrical system box body, such as Figure 1-Figure 6 As shown, the housing 2 in this embodiment is as Figure 4-5 As shown, it is a one-time molding structure, which includes a bridge plate 24 with a semicircular upper part, two side plates 25 located on both sides of the bridge plate and connected by the bridge plate, and an end plate that closes the two side plates and the rear end of the bridge plate 26. The front end of the shell 2 is provided with a eaves 27 protruding along the outer edge of the shell, and the bridging plate of the shell and the inner edge walls of the two side plates protrude respectively and are provided with assembly protrusions 21 for assembling. Threaded blind holes 23 are provided, and the shell seat 1 of embodiment 1, such as Figure 1-3 As shown, the housing base 1 has an outer edge surface that matches the shape of the inner edge surface of the eaves 27 of the housing 2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com