Temperature sensing assembly used for detecting surface temperature of induction cooker and mounting method thereof

A technology for sensing components and induction cookers, which is applied to thermometers, thermometers, and measuring devices that use directly heat-sensitive electric/magnetic elements, and can solve problems such as temperature measurement differences, pin heating, and temperature signal sampling error increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further description will be given below in conjunction with the accompanying drawings of the embodiments.

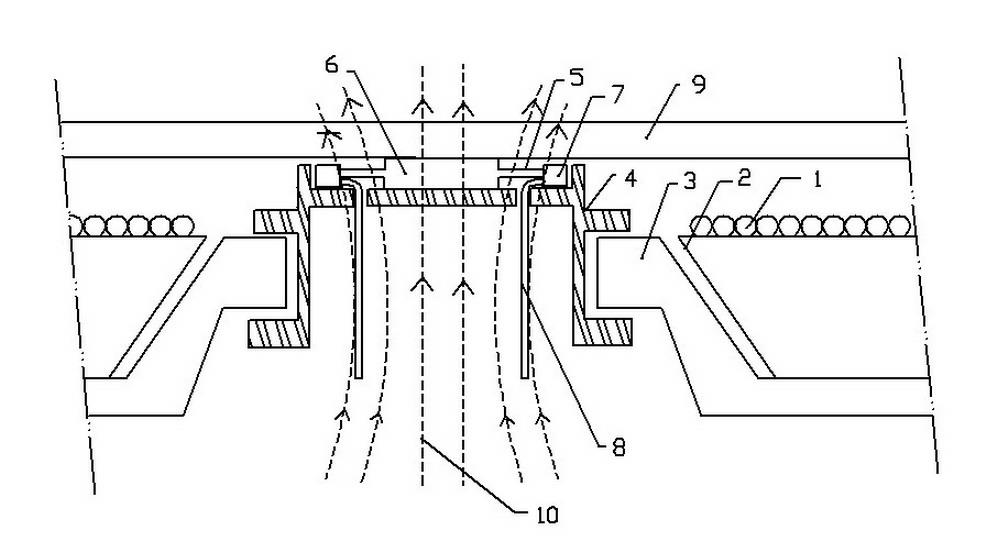

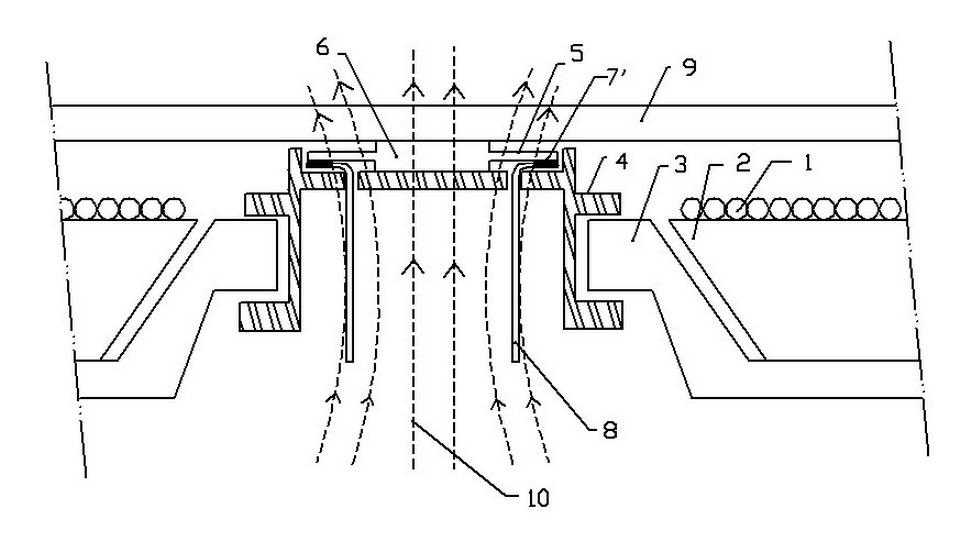

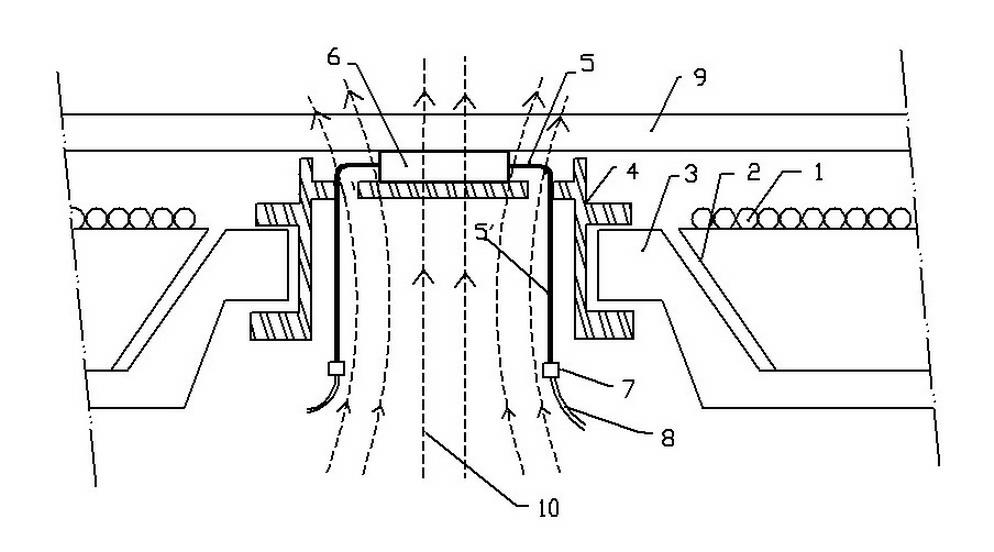

[0015] refer to figure 1 , the temperature sensing assembly embodiment 1 includes: a thermistor body 6, the two ends of the thermistor body 6 are respectively connected to straight pins 5, the thermistor body 6 and the two straight pins 5 are located at the central hole of the coil disk And, two wires 8, each wire 8 is riveted with a straight pin 5 at the two ends of the thermistor body 6 through a copper rivet 7, and the two wires The wire 8 passes downward through the inner cavity of the silicone plug 4 located in the dense area of magnetic force lines and is connected to the temperature signal processing unit on the circuit board in the induction cooker.

[0016] In the induction cooker, the temperature sensing assembly of embodiment 1 is installed such as figure 1 shown. figure 1 The middle coil disk is a traditional coil disk, which mainly includes a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com