Connecting structure of buckle plate

A gusset plate and splicing strip technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of high manufacturing cost, and achieve the effects of easy manufacturing, simple structure, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

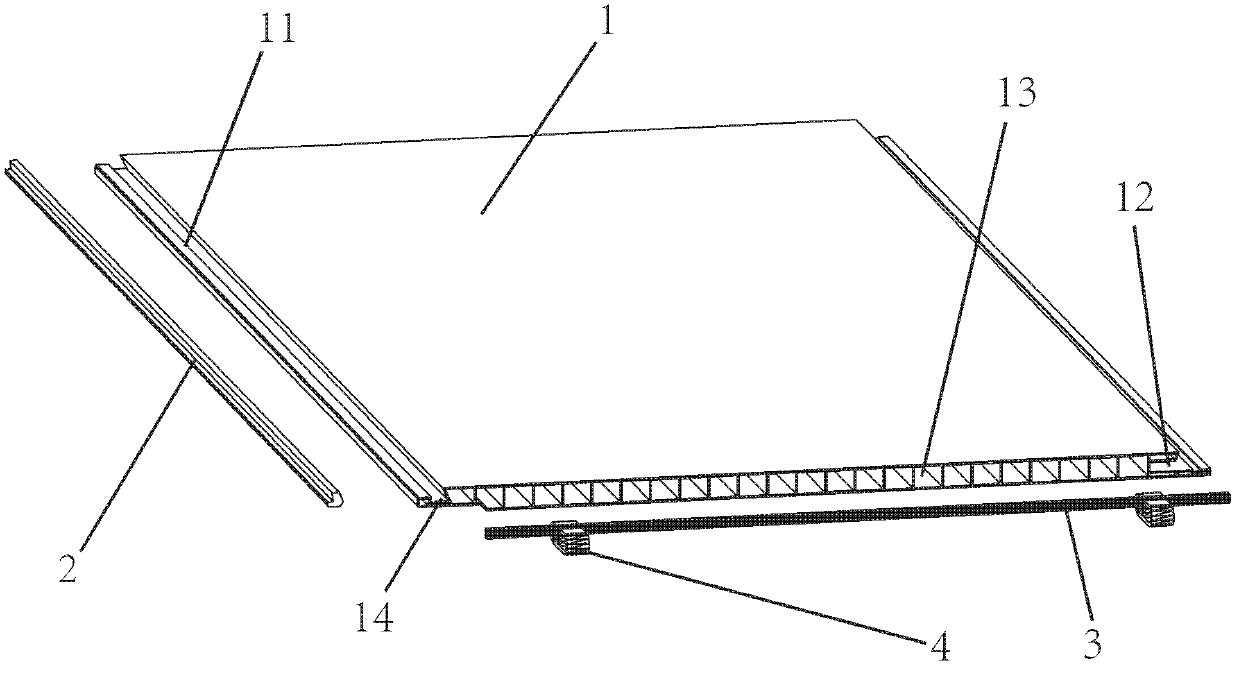

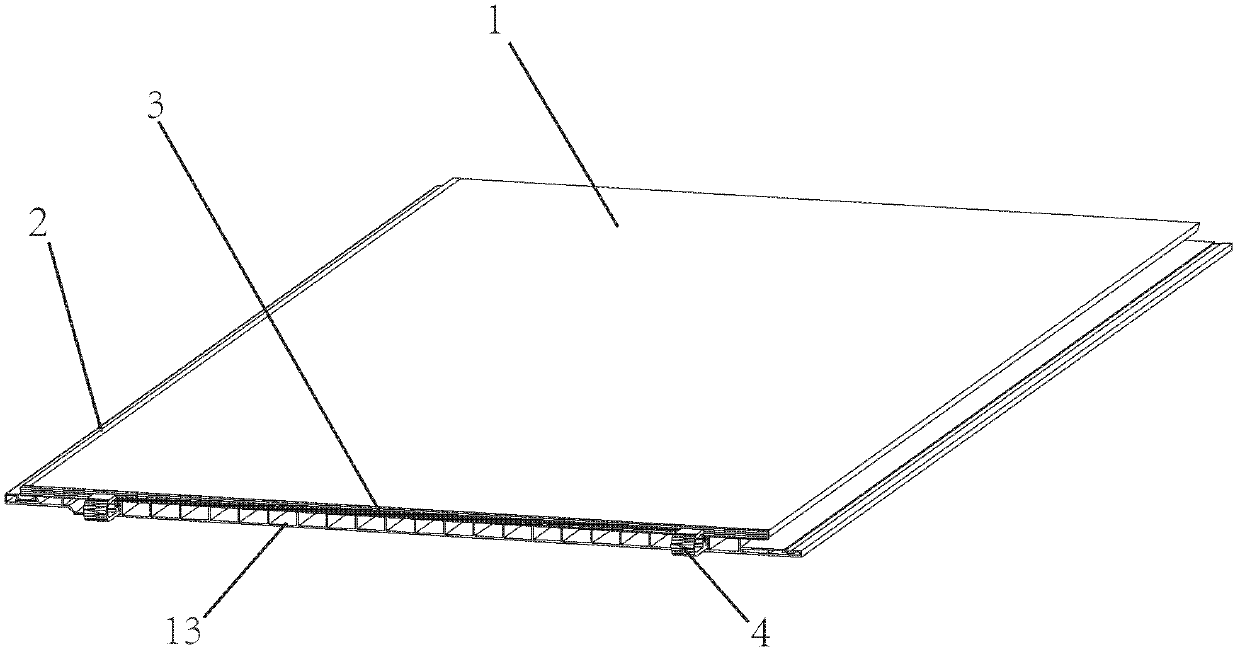

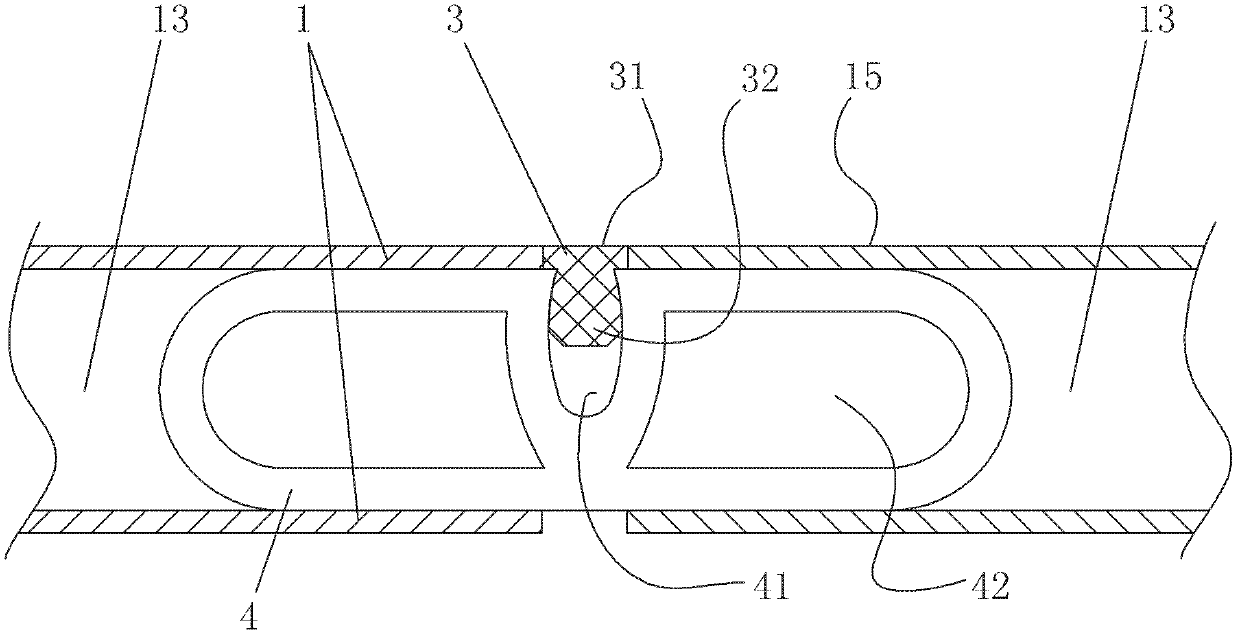

[0018] Such as figure 1 , figure 2 The gusset splicing structure shown includes an extruded gusset substrate 1, the left and right sides of the gusset substrate 1 are respectively the female side 12 and the male side 11, and the left and right adjacent gusset substrate 1's female and male sides Mutual fastening, a plurality of connecting ribs are arranged between the upper panel and the lower panel of the gusset base plate 1, and the front and rear ends of the gusset base plate 1 are composed of the upper panel, the lower panel and the connecting ribs to form a number of connecting rib grooves 13, which also include The first splicing strip 3 between the two gusset substrates 1 that are spliced front and back, the first splicing strip 3 has a visible surface 31 that can be seen between the two gusset substrates 1 that are spliced front and back, the first splicing strip 3 is on its visible surface The opposite side of 31 is connected with some splicing pieces 4 by concav...

Embodiment 2

[0021] A gusset splicing structure, which is different from Embodiment 1 only in that: the second splicing strip 2 and the gusset substrate 1 are integrally formed by two-color co-extrusion. Others are the same as in Example 1. In this way, the splicing effect is good, the cost is low, and the installation is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com