Novel CNG (compressed natural gas) steel cylinder fixing support

A technology for fixing brackets and cylinders, applied in the field of automobiles, can solve problems such as injuries to passengers or other devices, impact on rear seats, and cylinders detaching from brackets, etc., and achieves the effects of simple structure, reduced collision, and guaranteed safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention will be further described:

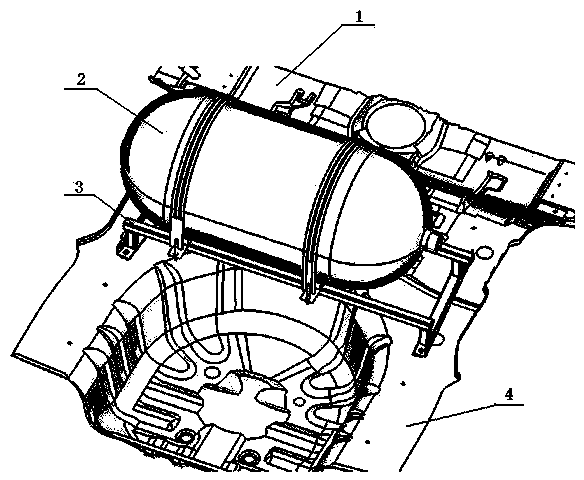

[0033] figure 1 A schematic diagram of the overall installation structure of the steel cylinder fixing bracket of the present invention is shown. The steel cylinder 2 is installed at the rear of the vehicle through the steel cylinder fixing bracket assembly 3, and is installed on the rear floor 4 in the trunk by bolts.

[0034] figure 2 It is a schematic diagram of the overall structure of the steel cylinder fixing bracket of the present invention. The steel cylinder fixing bracket assembly 3 consists of two upper metal belt assemblies 31, two lower metal belt assemblies 32, four metal belt fixing brackets 33, two beams 34, four Crossbeam fixed bracket 35 and two installation plates 36 etc. parts are made up. The lower metal belt assembly 32 plays the role of supporting the steel cylinder, and the upper metal belt assembly 31 plays the role of clamping the steel cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com