Carrousel coiler with reel that can be replaced rapidly

A coiler and coil replacement technology, which is applied in the field of strip steel coilers, can solve the problems of long time consumption of coils, large size of revolving gearbox, tedious and time-consuming work of gap adjustment, etc., so as to reduce maintenance costs and shorten the required time. Save time and save troublesome work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

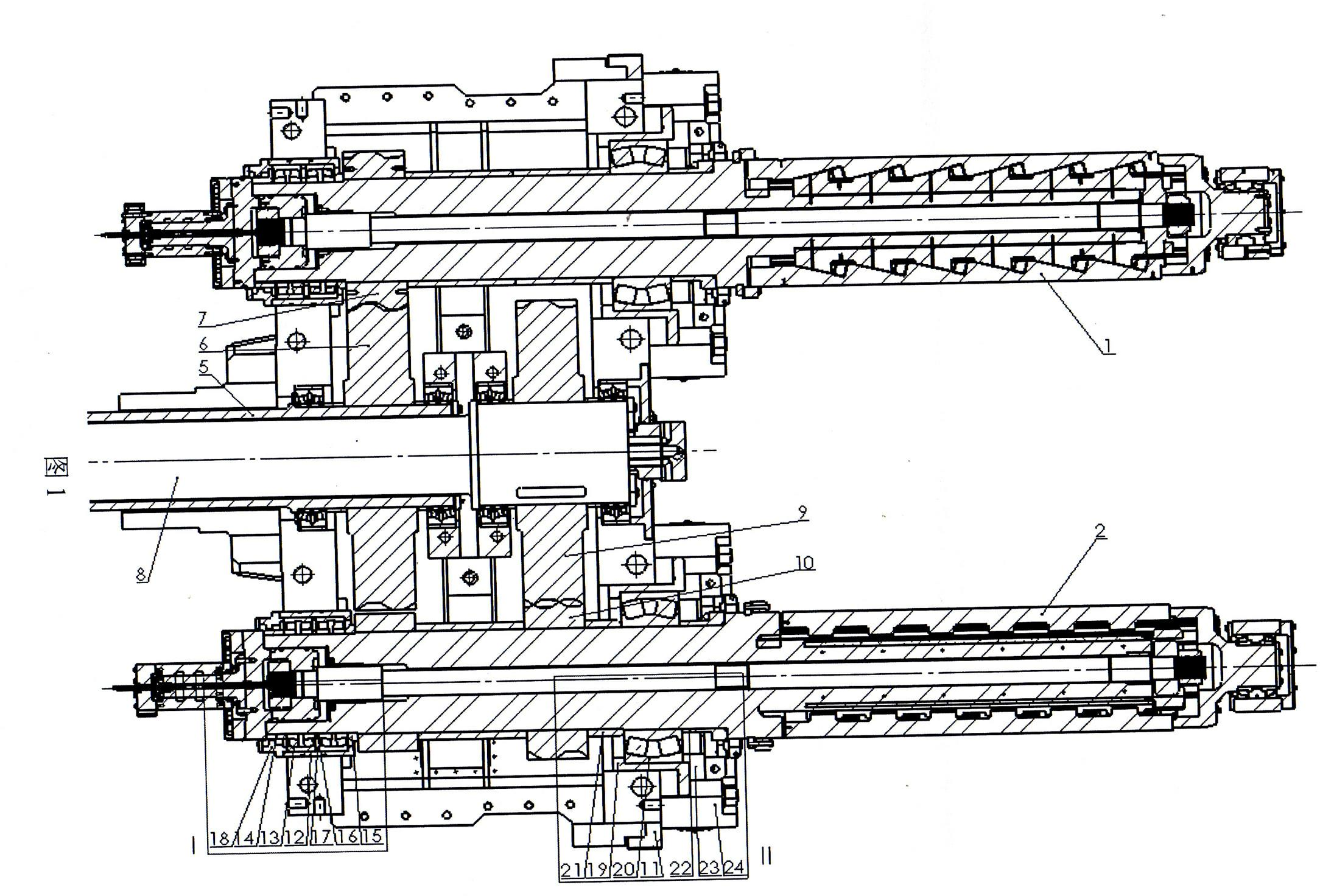

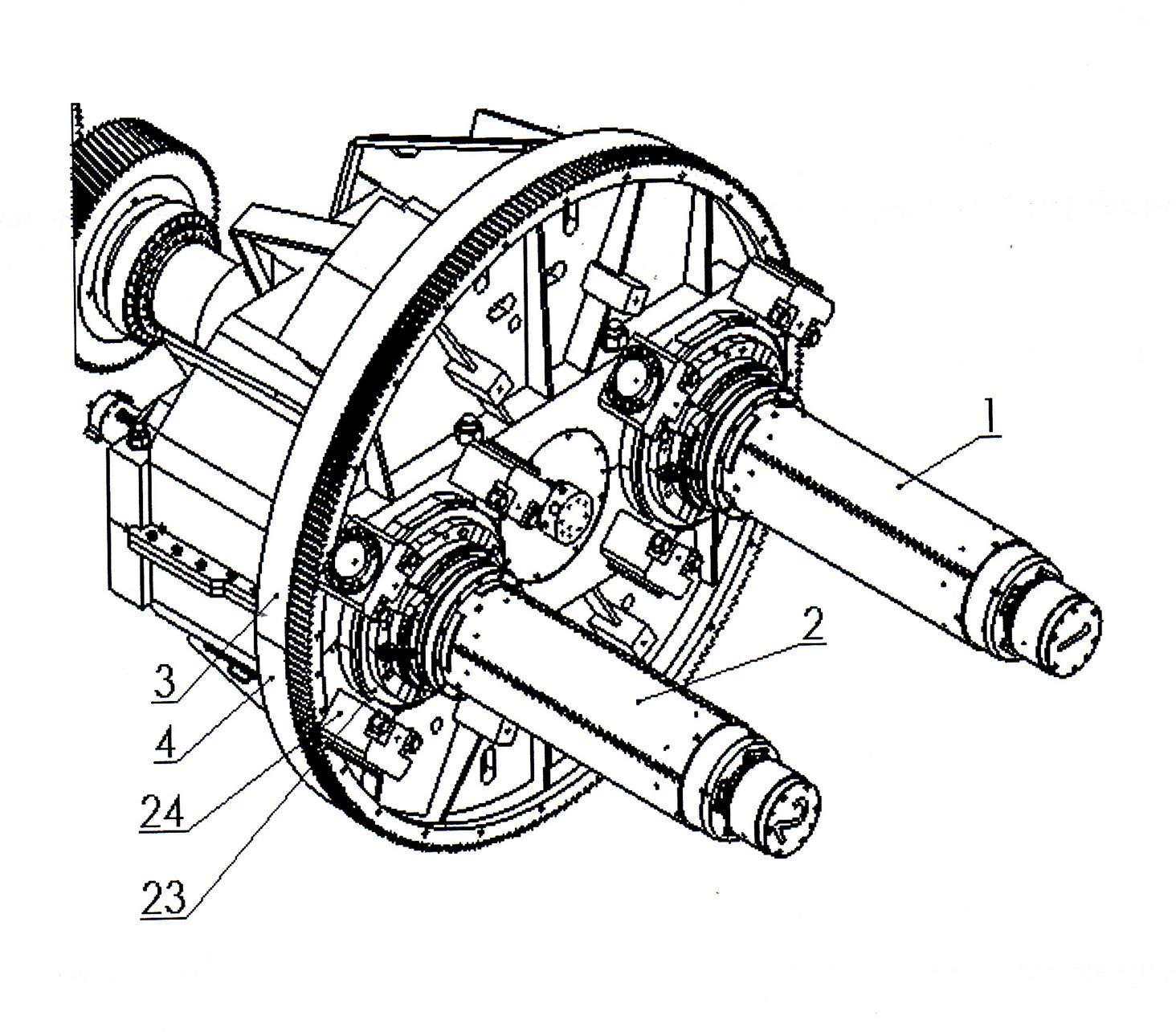

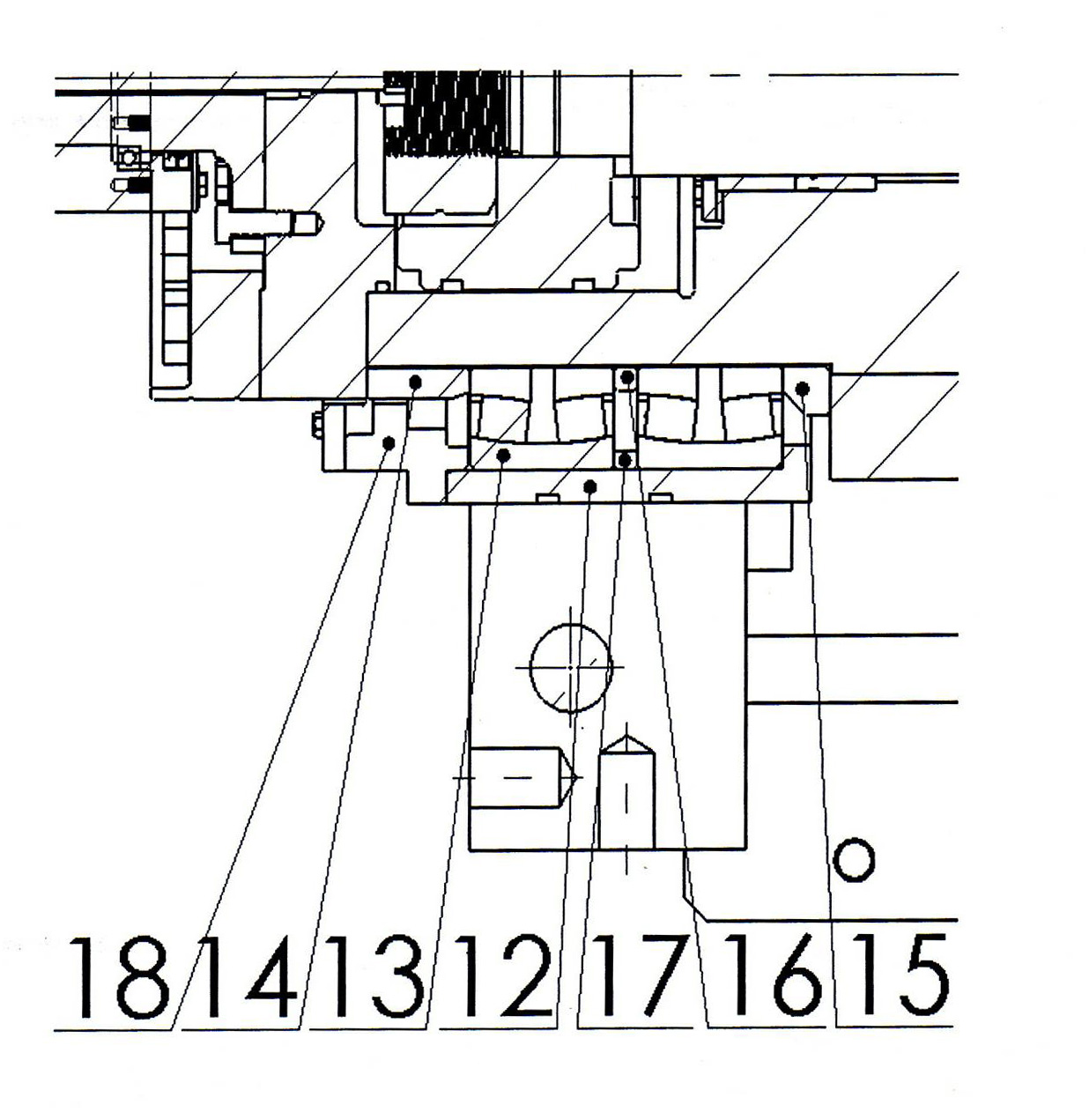

[0016] exist figure 1 with figure 2 The carrousel coiler that can quickly replace the reel is shown, the reel shafts 1 and 2 with the same structure (except for the different installation positions of the transmission gears 7 and 10) are located in the revolving gear boxes 3 and 4 Inside, the reel shaft 1 drives the gears 6 and 7 to engage with the gears 6 and 7 to rotate and curl through the outer sleeve shaft 5; the reel shaft 2 drives the gears 9 and 10 to engage with the inner shaft 8 to perform the rotation and curl; the outer edge of the revolution gear box 3 and 4 is installed A ring gear 11 is arranged to drive the gear box to revolve. On the side close to the expansion and contraction cylinder, a sleeve cup 12 is provided on the reel shaft, and a bearing 13 is arranged in the sleeve cup, and the inner ring of the bearing is axially positioned with the shaft sleeves 14, 15 and the spacer ring 16; The ring is axially fixed in the above-mentioned sleeve cup through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com