Gas-fog separator

A separator and aerosol technology, which is applied in the field of exhaust gas purification and treatment, can solve the problems of too many damping discs, increased cost, affecting the effect of demisting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

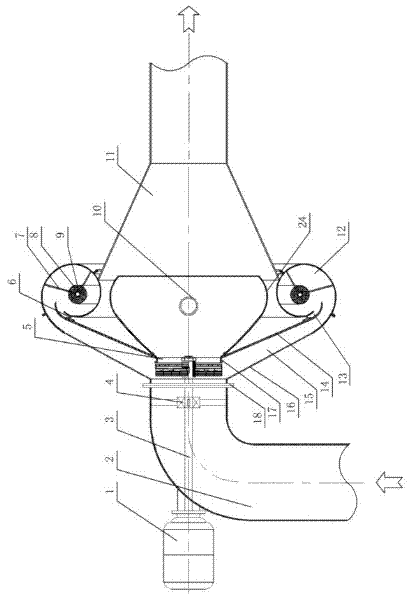

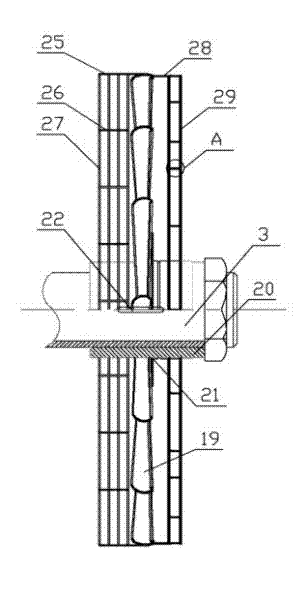

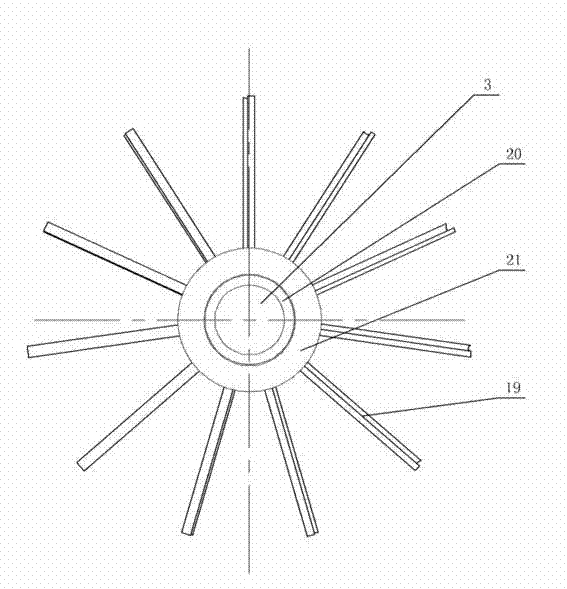

[0023] Such as figure 1 As shown, the present invention is an aerosol separator for separating airflow mixed with water mist in the mist eliminator of an atomizing dust removal device, and it includes a cylinder whose front end is connected to an air inlet pipe 2. A motor 1 is installed at the bend of the intake duct 2, and the output shaft 3 of the motor 1 extends into the intake duct 2 and faces the cylinder. A bearing 4 is fixedly installed in the intake duct 2, and the output shaft 3 of the motor 1 penetrates the inner hole of the bearing 4, so as to prevent the shaft 3 of the motor 1 from shaking during high-speed rotation. An aerosol separation blade is installed on the output shaft 3 of the motor 1. The aerosol separation blade can separate the water mist and the air flow. The air flow is discharged backward through the aerosol separation blade, and the water mist is passed through the aerosol separation blade. The leaves condense into water droplets after action, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com