Fuel supply system

A fuel supply system and fuel technology, applied in the direction of the charging system, fuel injection device, fuel air filter, etc., can solve the problem of no additional fuel distribution conduit installation, etc., to achieve simple and cost-saving, simple and low-manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

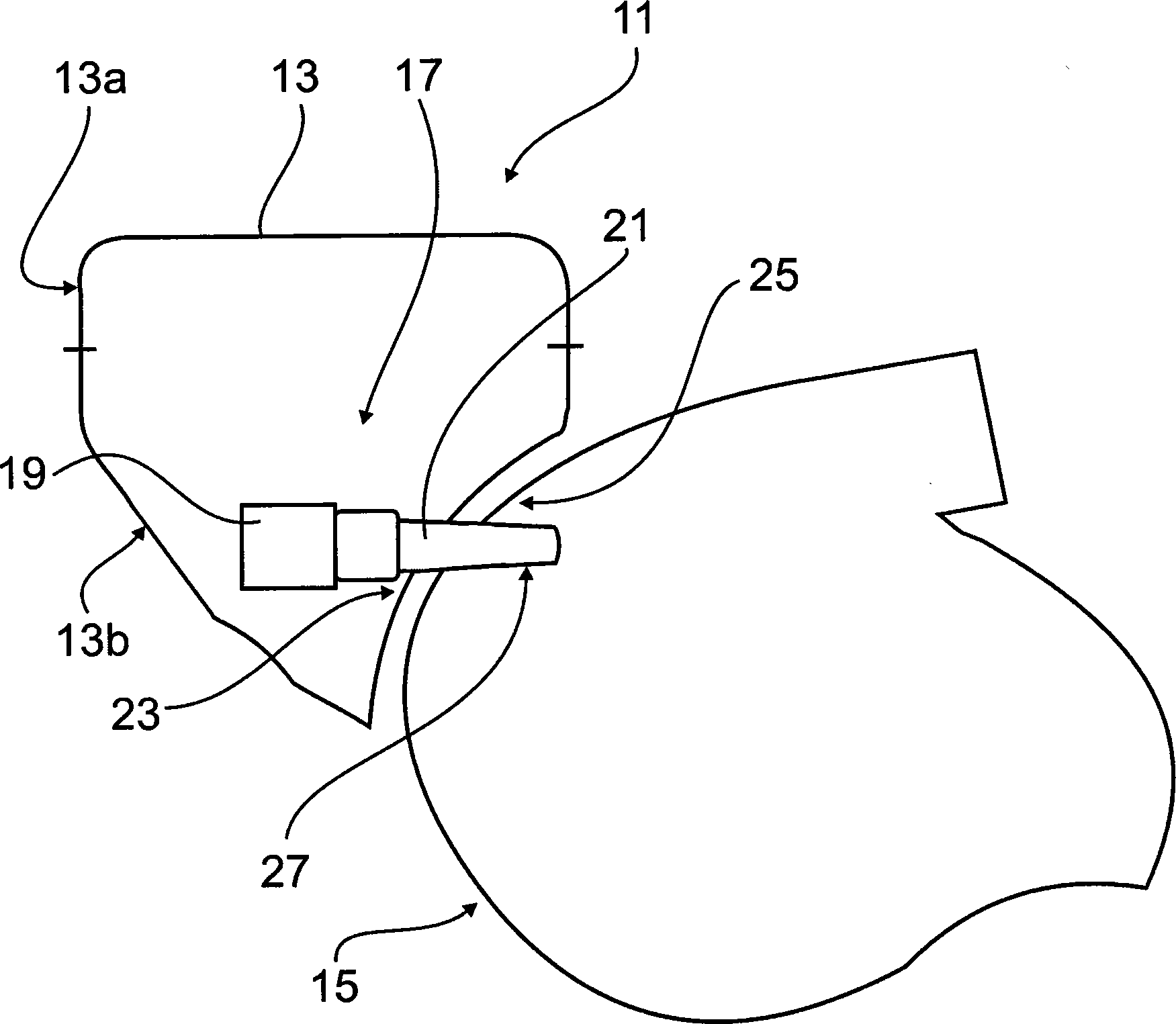

[0023] attached figure 1 Components of a fuel supply system are shown, which supply an internal combustion engine (not shown) with a combustible mixture from intake air and fuel. An air filter module or air filter box 11 with a housing 13 and a filter element, not shown, arranged in the housing 13 for cleaning the intake air is attached to the suction device 15 via a holding device, not shown. , the intake device 15 conveys the intake air purified by the filter element to the cylinders of the internal combustion engine.

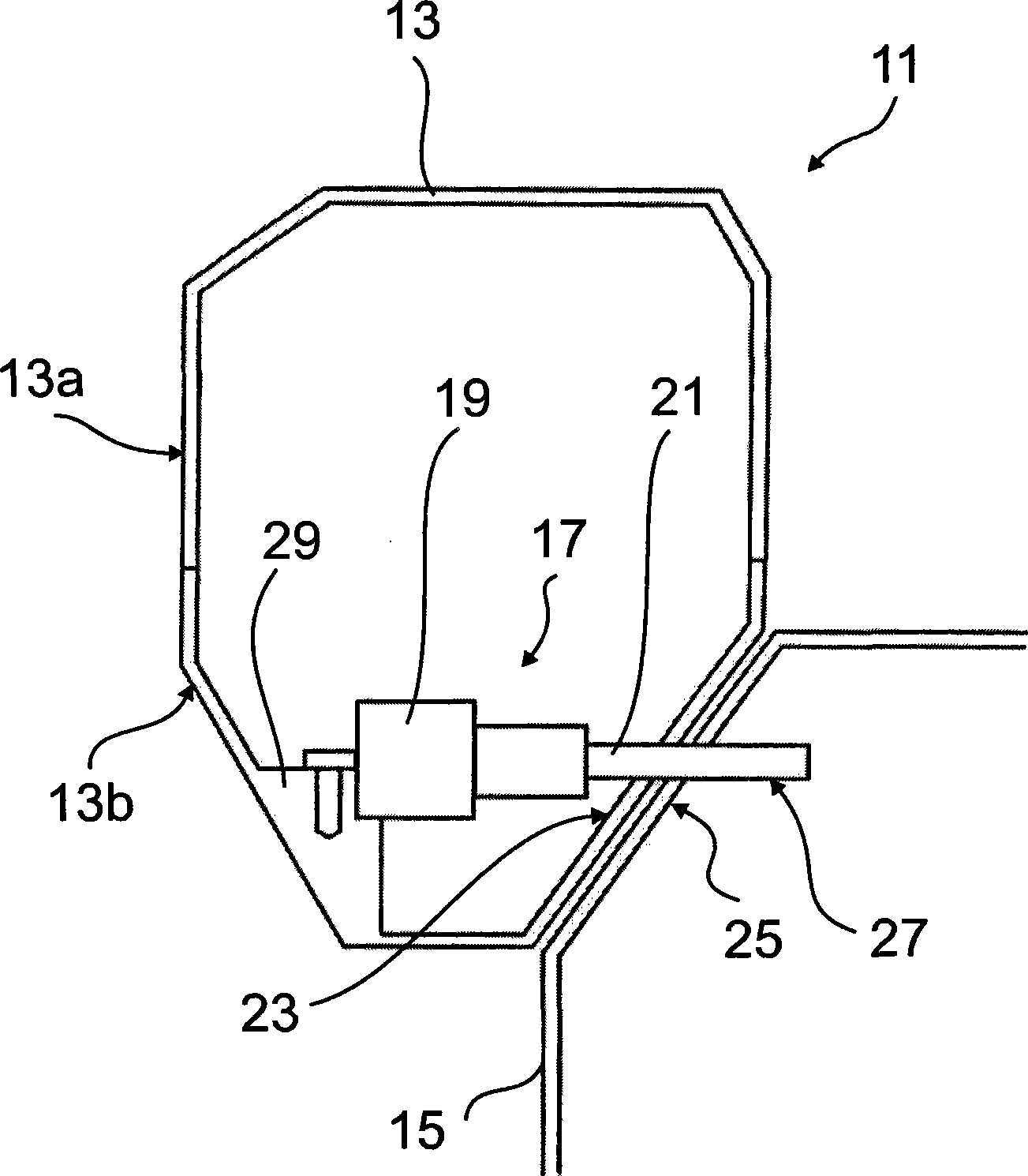

[0024] as attached figure 2 As shown, the air filter housing 13 is divided into an upper part 13a and a lower part 13b, wherein the fuel injection device 17 is integrated in the lower part 13b. The fuel injection device 17 is used to inject fuel 17 into the air intake device 15 to generate a combustible gas / fuel mixture. The fuel injection device 17 comprises a fuel distribution line 19 and a plurality of injection nozzles 21 connected to the fuel distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com