High pressure engine master device for purification and ultramicro emission of various low calorific value waste liquor and gases

A technology of exhaust gas purification and low calorific value, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of low energy saving effect and poor engine feasibility, and achieve the effect of simple structure, stable performance and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

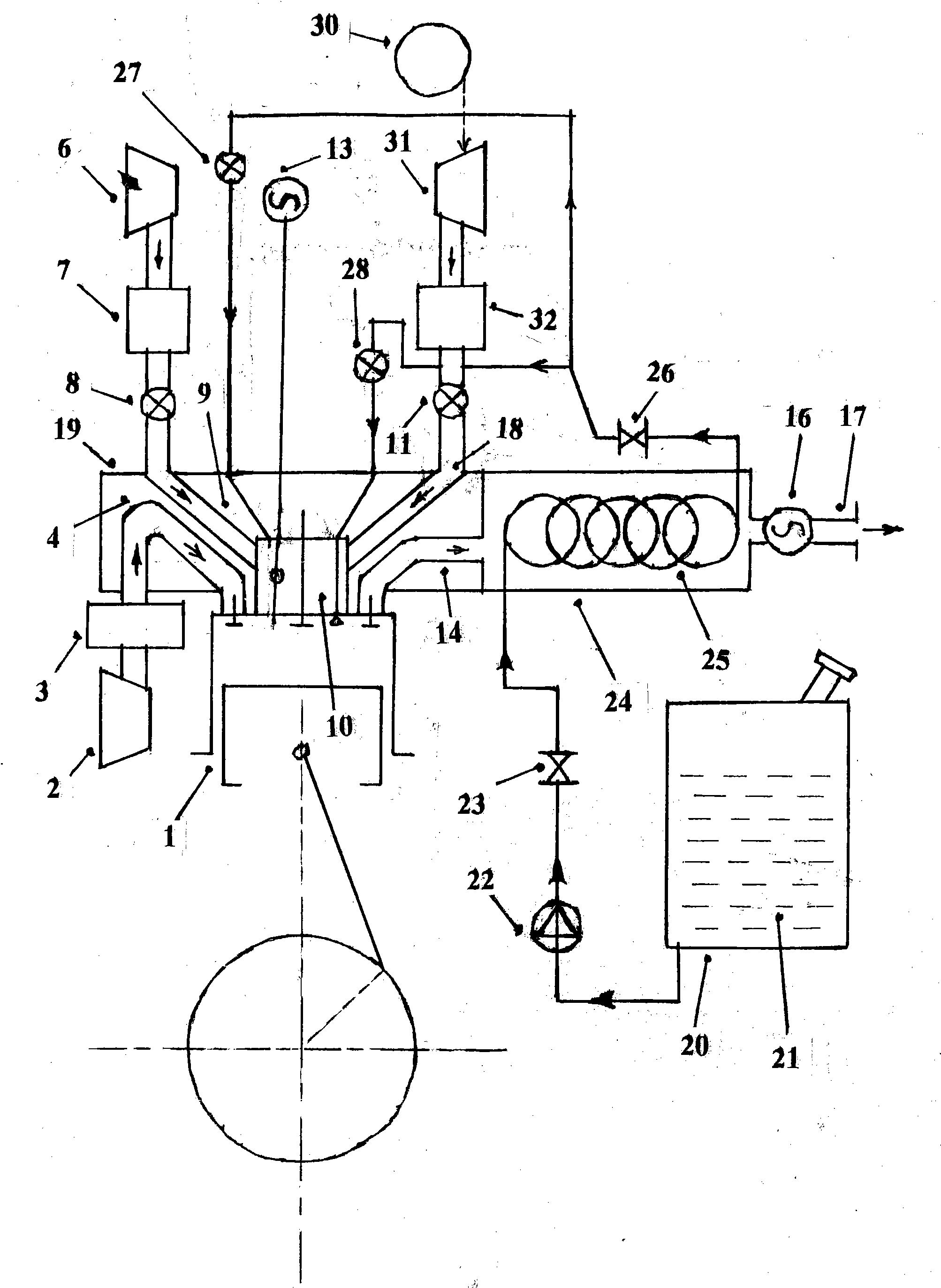

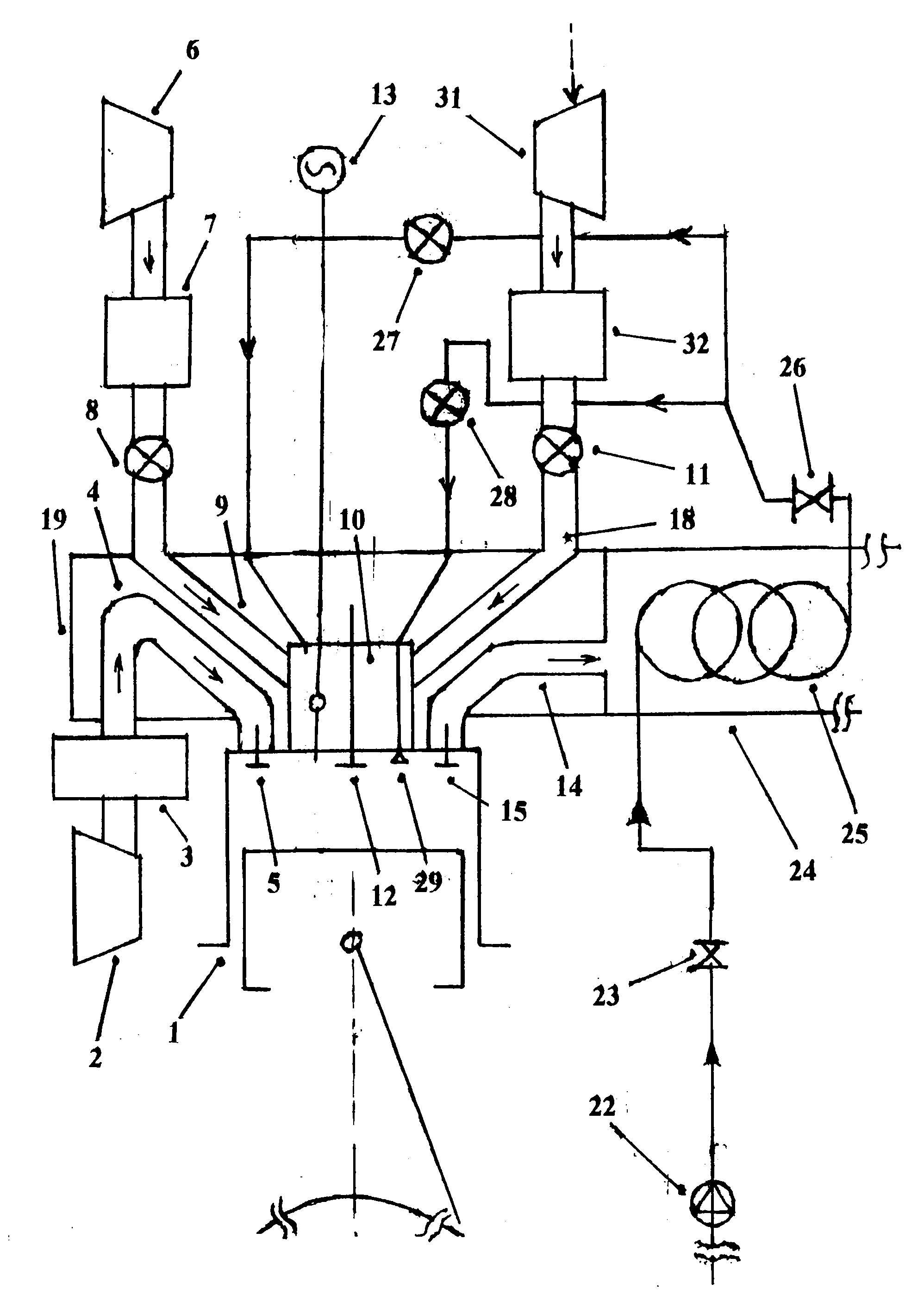

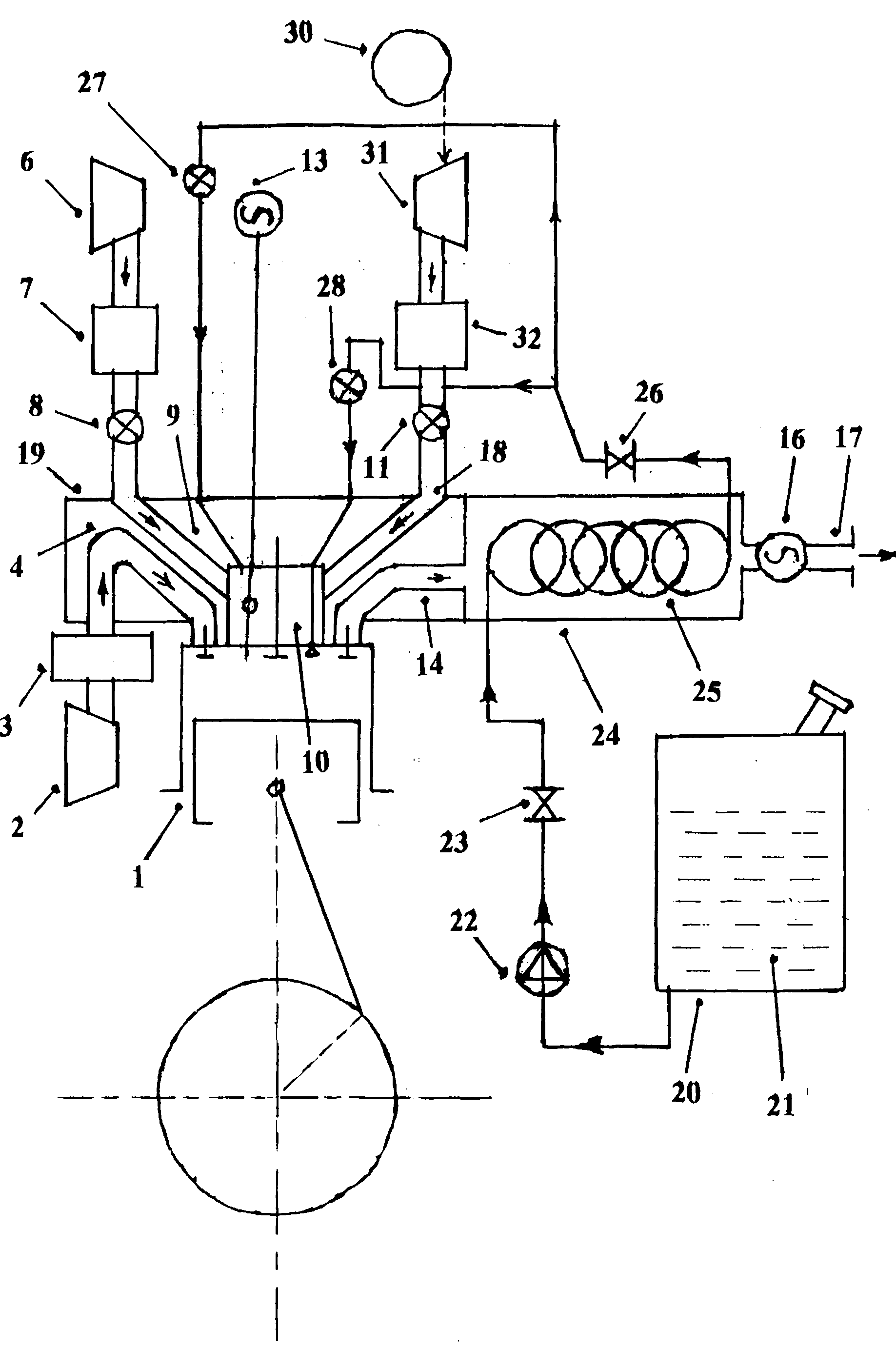

[0011] exist figure 1 Among them, an air high-pressure supercharger (2), a high-pressure air storage tank (3), and a high-pressure air input pipe (4) are arranged in the high-pressure air intake system on the thin homogeneous strong-combustion stable-combustion high-pressure cylinder (1), One end of the high-pressure air storage tank (3) is connected to the air high-pressure supercharger (2) and the other end is connected to the high-pressure air input pipe (4), and one end of the high-pressure air input pipe (4) is connected to the thin homogeneous strong-combustion stable-combustion high-pressure The top connection of the cylinder (1). In the residual gas discharge system on the thin homogeneous strong combustion stable combustion high-pressure cylinder (1), a residual gas output pipe (14), various waste liquid water alcohol reformers (24), various waste liquid water alcohol Pipeline (25), thermoelectric generator (16), residual gas discharge pipe (17), one end of the therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com