Air curtain and water mist linked system for preventing and controlling dust on comprehensive excavation surfaces

A linkage system, air curtain technology, applied in the direction of dust prevention, fire prevention, safety devices, etc., can solve the problems of unsatisfactory dust prevention effect, bulky and cumbersome, and easily blocked nozzles, so as to improve dust reduction efficiency and water utilization rate, Safe and reliable operation, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

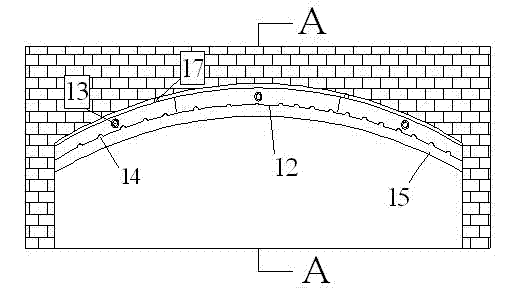

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0013] As shown in the accompanying drawings, the air curtain and fine water mist linkage system for preventing and controlling flour dust in fully mechanized excavation of the present invention consists of a water inlet pipe 1, a pipeline filter 2, a main air inlet pipe 3, a linkage valve 4, a branch air inlet pipe 5, a branch Air intake pipe 6, regulating valve 7, pressure gauge 8, air curtain generator 9, fine water mist generator 10 and fine water mist delivery pipe 11 constitute. A quick connector is provided at the inlet of the water inlet pipe 1 and the main air inlet pipe 3, so as to quickly connect with the pressure air pipeline and the pressure water pipeline of the working surface. The initial section of the water inlet pipe 1 is provided with a pipeline filter 2, which is used to remove water pollutants and purify Water quality to protect the no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Seam width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com