Separated self-propelled coal mine underground drill rig

A tunnel drilling rig, self-propelled technology, applied in the direction of rotary drilling rig, percussion drilling, rotary drilling, etc., can solve the problems of self-propelled, large size of the whole machine, etc., to improve drilling accuracy and reduce failures rate, improve the effect of climbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described

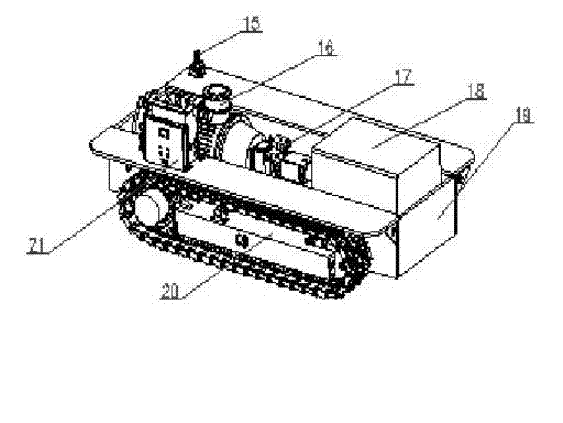

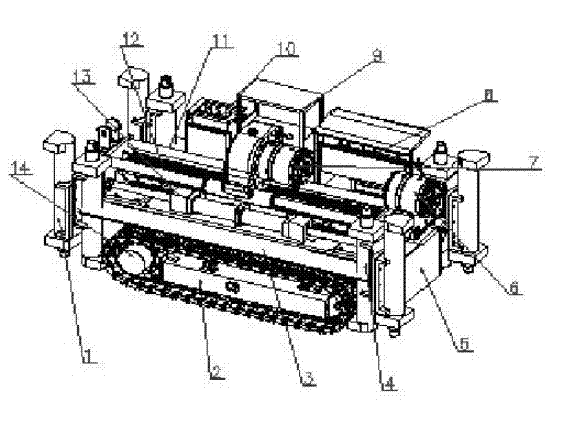

[0022] It can be seen from Fig. 1 that for the split self-propelled coal mine tunnel drilling rig, walking crawlers 2 are installed on both sides of the front car body 5, and the two flanges on the traveling reducer 14 are respectively connected with the driving sprocket and the crawler frame. Two lower support cylinders 1 are respectively installed on the front and rear sides of the track, one upper support cylinder 4 is installed on the right front, and two upper support cylinders 4 are installed on the rear, which are respectively fixed on the front car body 5; the left side of the car body is the control box 8, An inclinometer host computer composed of a computer 9 is installed on the right side of the control box, and a vacuum electromagnetic starter 10 and a hydraulic radiator are fixed beside the computer; a feed mechanism 11 is installed on the right side of the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com