Enhanced advanced oxidation procedure

An advanced oxidation and high-energy technology, applied in the field of purification, can solve unfriendly problems and achieve excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Enhanced Advanced Oxidation Method AOP

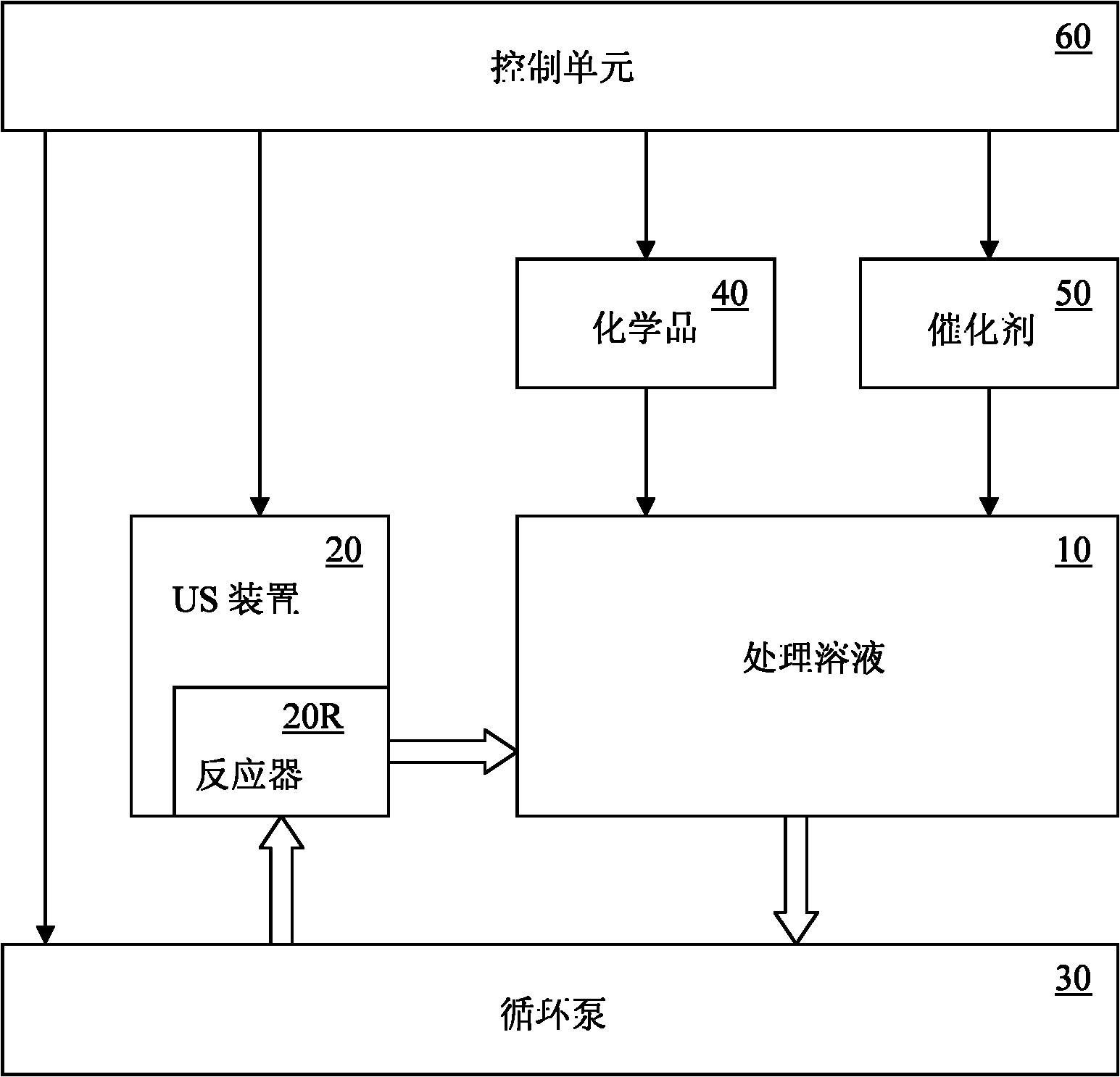

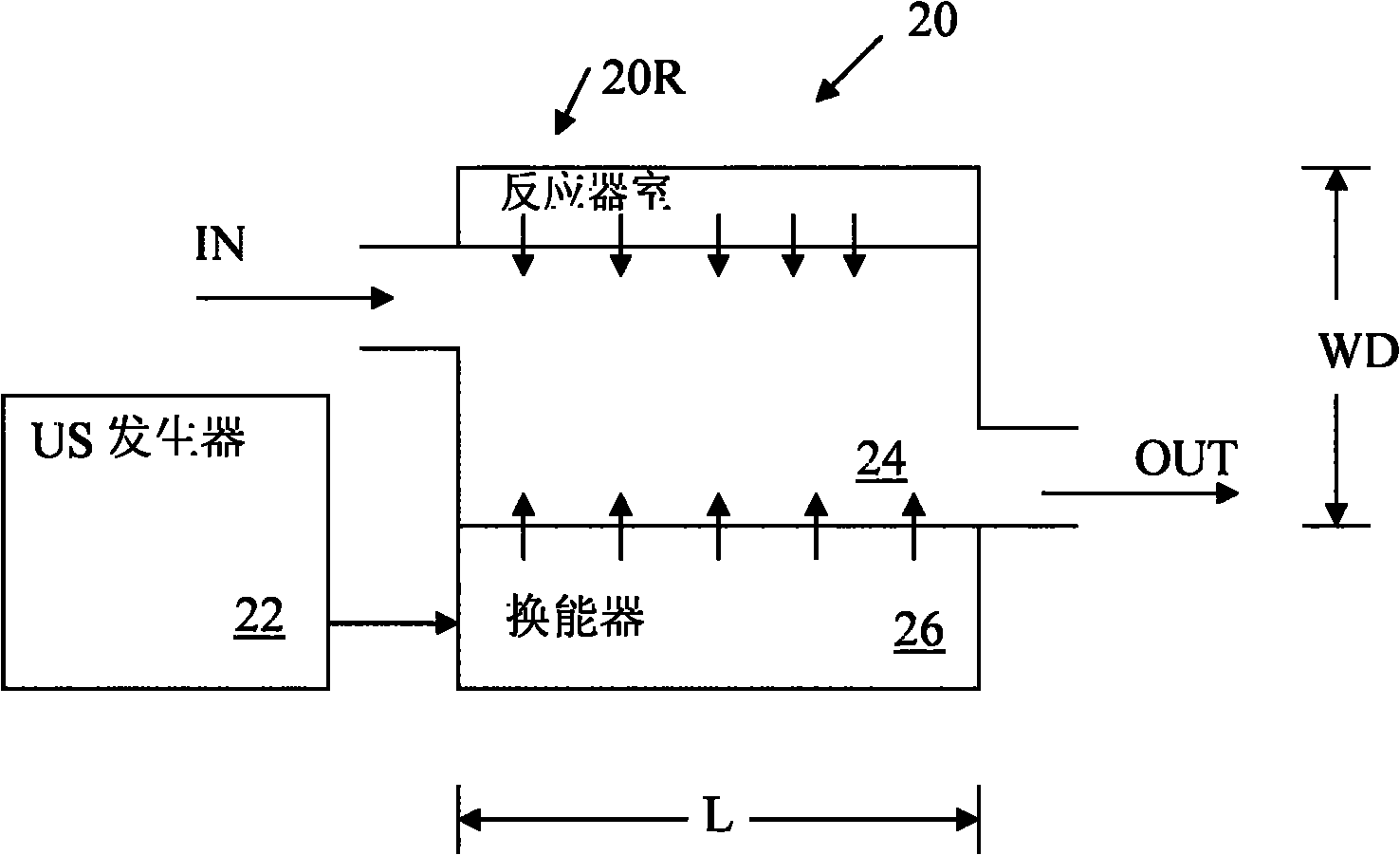

[0025] figure 1 is a simplified block diagram showing a system based on the ultrasonic / Fenton reaction for purification of industrial wastewater for operating enhanced AOP. The enhanced AOP operates a special ultrasonic apparatus and method on a volume of Vo of a treatment solution 10 containing toxic organic substances to degrade organic substances that cannot be treated by ordinary biodegradation methods in the presence of oxidative chemicals and catalysts.

[0026] Enhanced AOP may be part of a multi-stage approach that includes one or more different preprocessing, intermediate, and postprocessing processes. For example, the pretreatment process may include removal of oily materials, solids suspended in the wastewater treatment solution, and suspended solids sediments derived from dissolved solids treated by chemical reactions as well known to those skilled in the art.

[0027] As another example of a preliminary treatment s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com