Electric distribution box

A junction box and electrical technology, applied in the direction of electrical components, etc., can solve the problems of unfavorable workshop production site customization management, messy production site lines and pipelines, and inability to ensure safe production, so as to protect the interests of employees, simple structure, and easy installation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

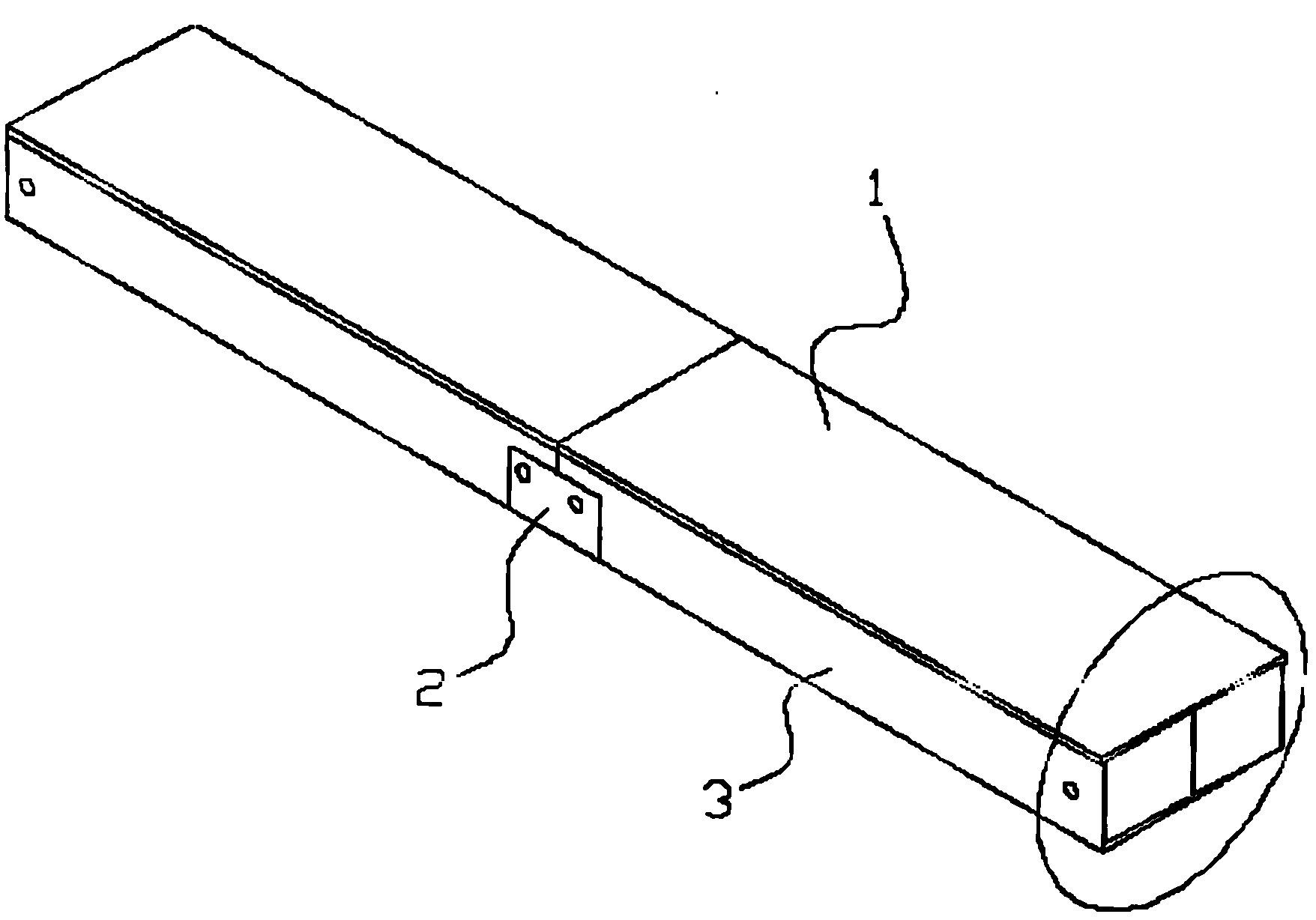

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments and illustrations.

[0013] Such as figure 1 , figure 2 As shown, an electrical junction box includes a box body 3 and a box cover 1 arranged on the upper end of the box body 3, and a distribution board 5 is longitudinally arranged in the box body 3, and the distribution board 5 divides the inner space of the box body into circuits The part 6 and the gas path part 4 are provided with connecting holes 7 at both ends of the sides of the box body 3 , and the connecting holes 7 are used for installing the connecting plate 2 .

[0014] Both the box body 3 and the box cover 1 are made of metal material, and the box cover 1 is provided with a folded edge downward.

[0015] When laying the circuit and air circuit in the workshop, first install and fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com