Base of inspection well

A technology for inspecting wells and well bases, applied to waterway systems, drainage structures, water supply devices, etc., can solve problems such as blockage and easy retention of dirt, and achieve the effects of avoiding blockage, smooth drainage, and avoiding wrong installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

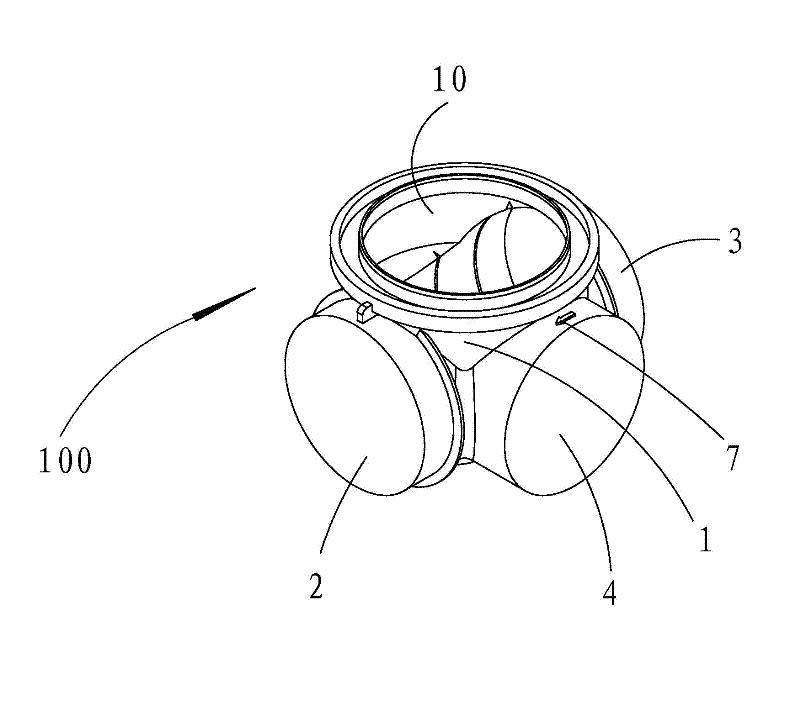

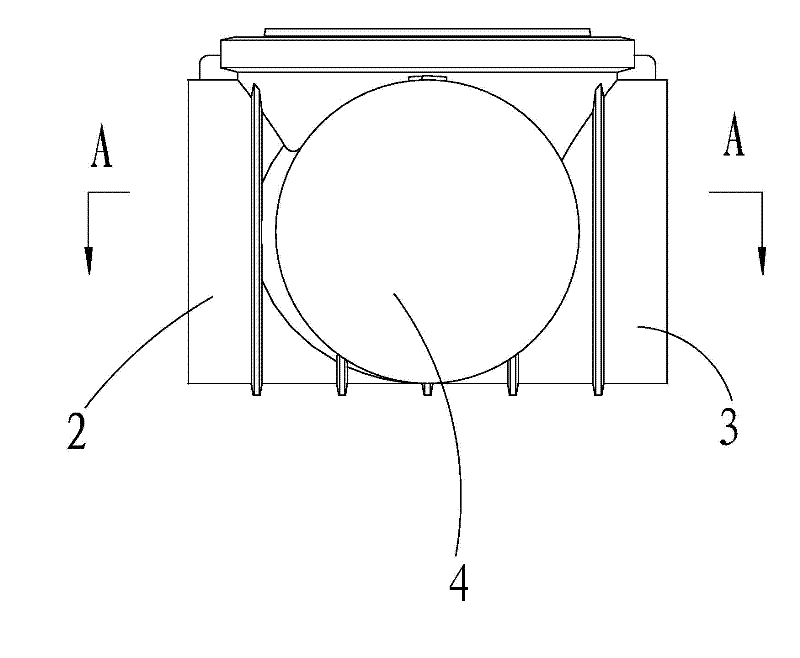

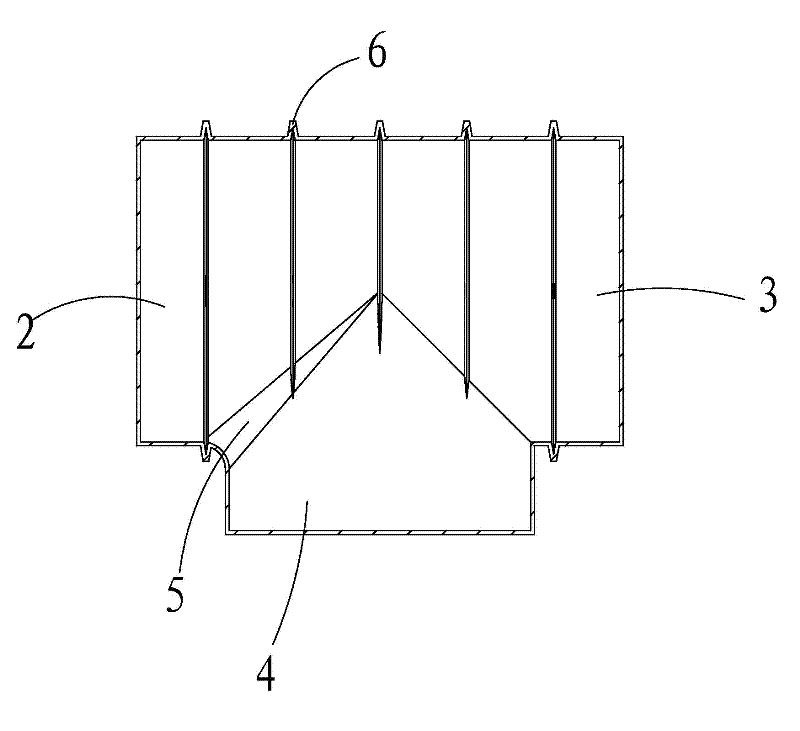

[0015] see Figure 1 to Figure 3 , an inspection well base 100, the inspection well base 100 includes: a base body 1, a first interface 2 disposed on one side of the base body 1, a second interface 3 disposed on the other side of the base body 1, and a second interface 3 disposed on the base body The third interface 4 at one end of the body 1 is provided with an opening 10 above the base body 1 , and a diversion groove 5 is provided at the connection between the third interface 4 and the first interface 2 . The first, second and third interfaces are all sealed. The advantage of this design is that the construction is more flexible. On the construction site, matching openings can be provided on the seal according to the specific size of the connecting pipeline. The inspection well base 100 is made of plastic. At least one reinforcing rib 6 is provided on the outside of the inspection well base 100 , so as to increase the structural strength of the inspection well base 100 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com