Clamping device

A technology of a clamping device and a driving device, applied in the field of machining, can solve the problems of low workpiece accuracy and workpiece error, and achieve the effects of long service life, high positioning accuracy and low friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

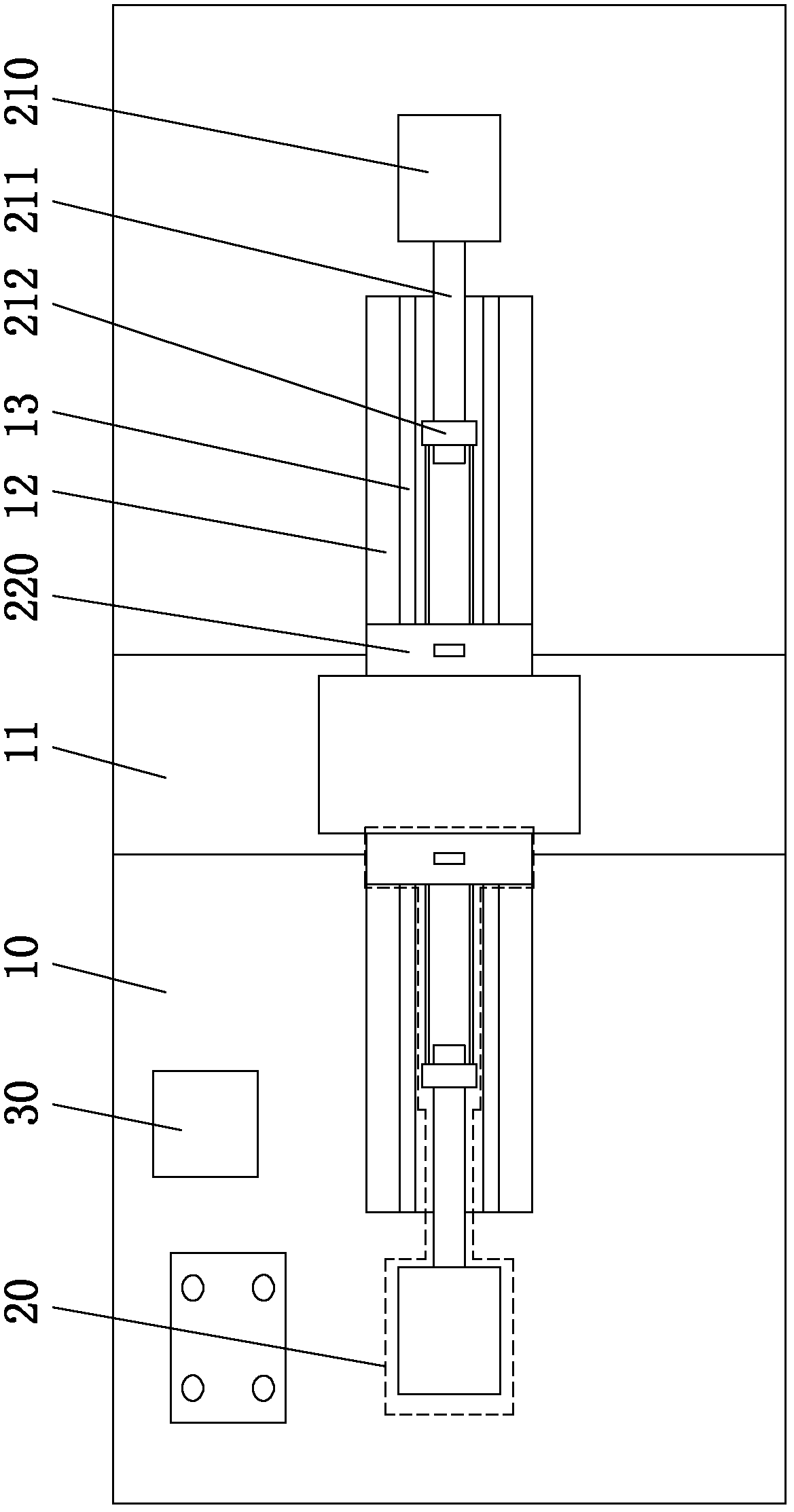

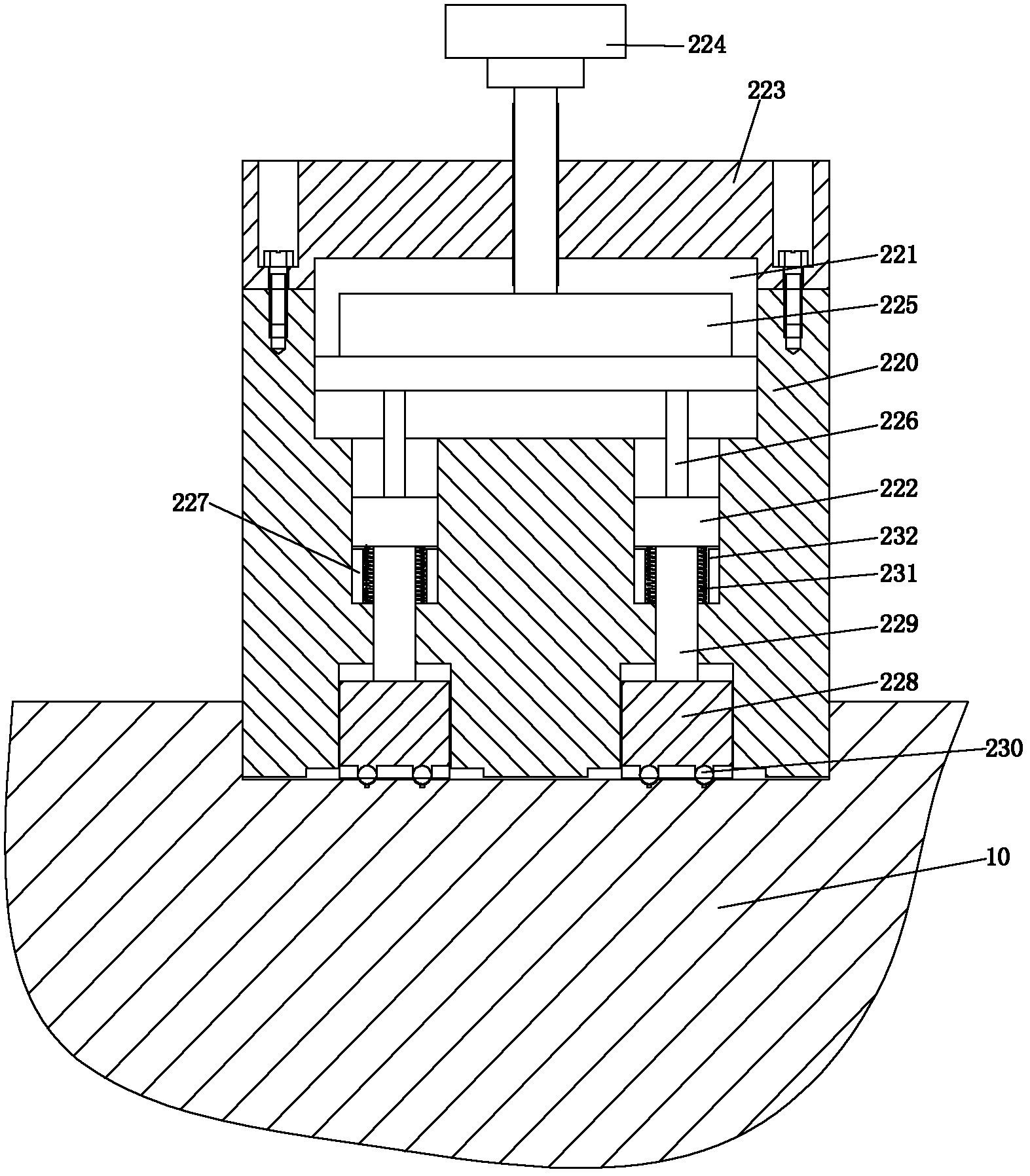

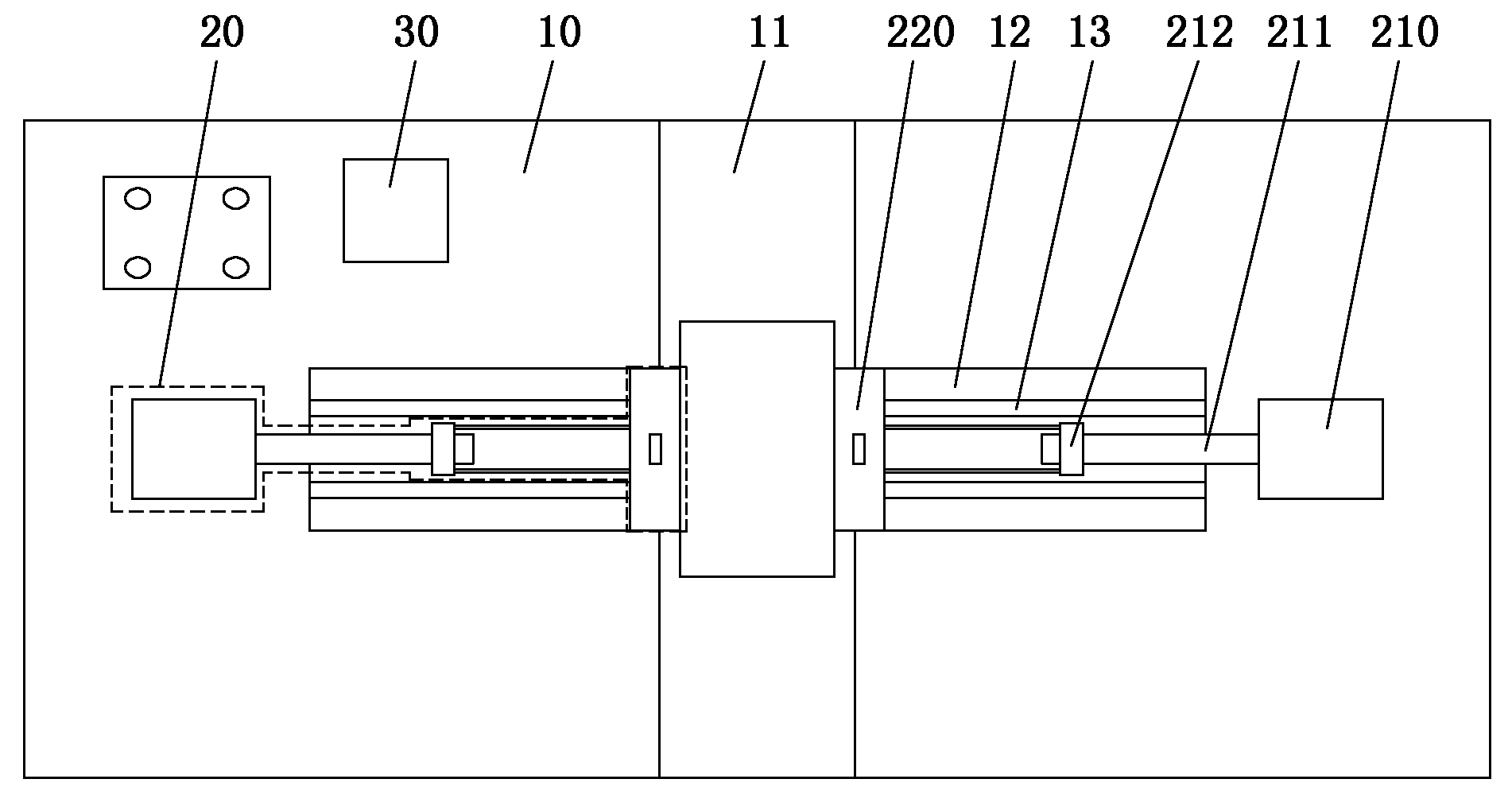

[0013] refer to figure 1 with figure 2 , the clamping device of the present invention is mainly composed of a workbench 10, a clamping mechanism 20 and a controller 30, the clamping mechanism 20 and the controller 30 are all assembled on the workbench 10, and each part is described in detail below:

[0014] The workbench 10 is mainly used to support the clamping mechanism and the controller. The middle area of the workbench 10 is the workpiece positioning area. During use, the workpiece is placed in the positioning area 11, and the workpiece can be pre-positioned through the positioning area. The workbench is provided with chute 12 located on the left and right sides of the workpiece positioning area, and a chute 13 for cooperating with the rolling element device in the clamping mechanism is provided at the bottom of each chute, when the clamping mechanism When the jig is switched from the sliding mode to the rolling mode, the rolling element device will fall into the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com