Automatic sheller for shrimp products

A technology of shelling machine and products, which is applied in the processing of shrimp/lobster, etc. It can solve the problems of low work efficiency, product pollution, and insufficient processing quantity, etc., and achieve the effect of high work efficiency, convenient use, and convenient mechanical shelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

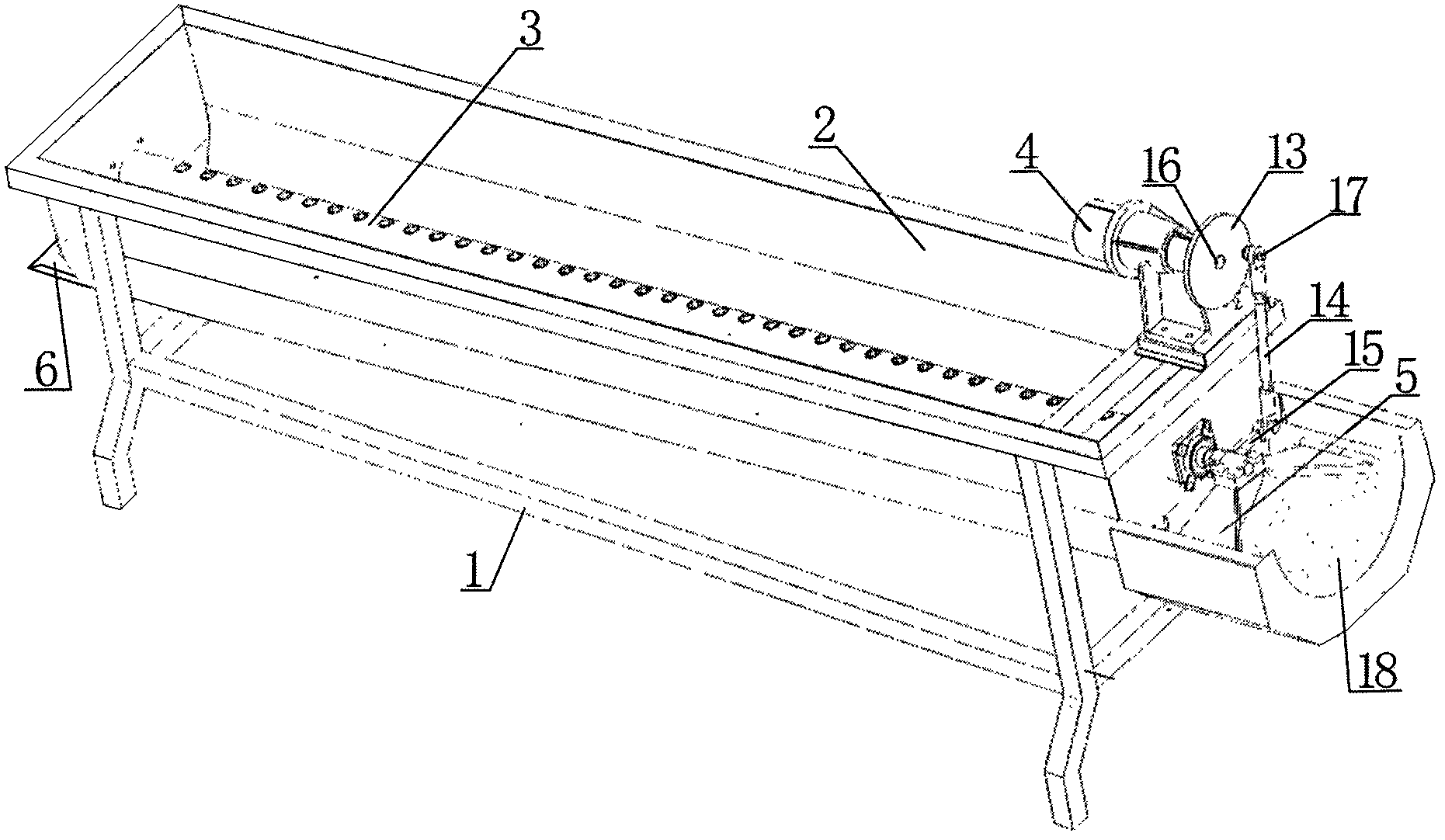

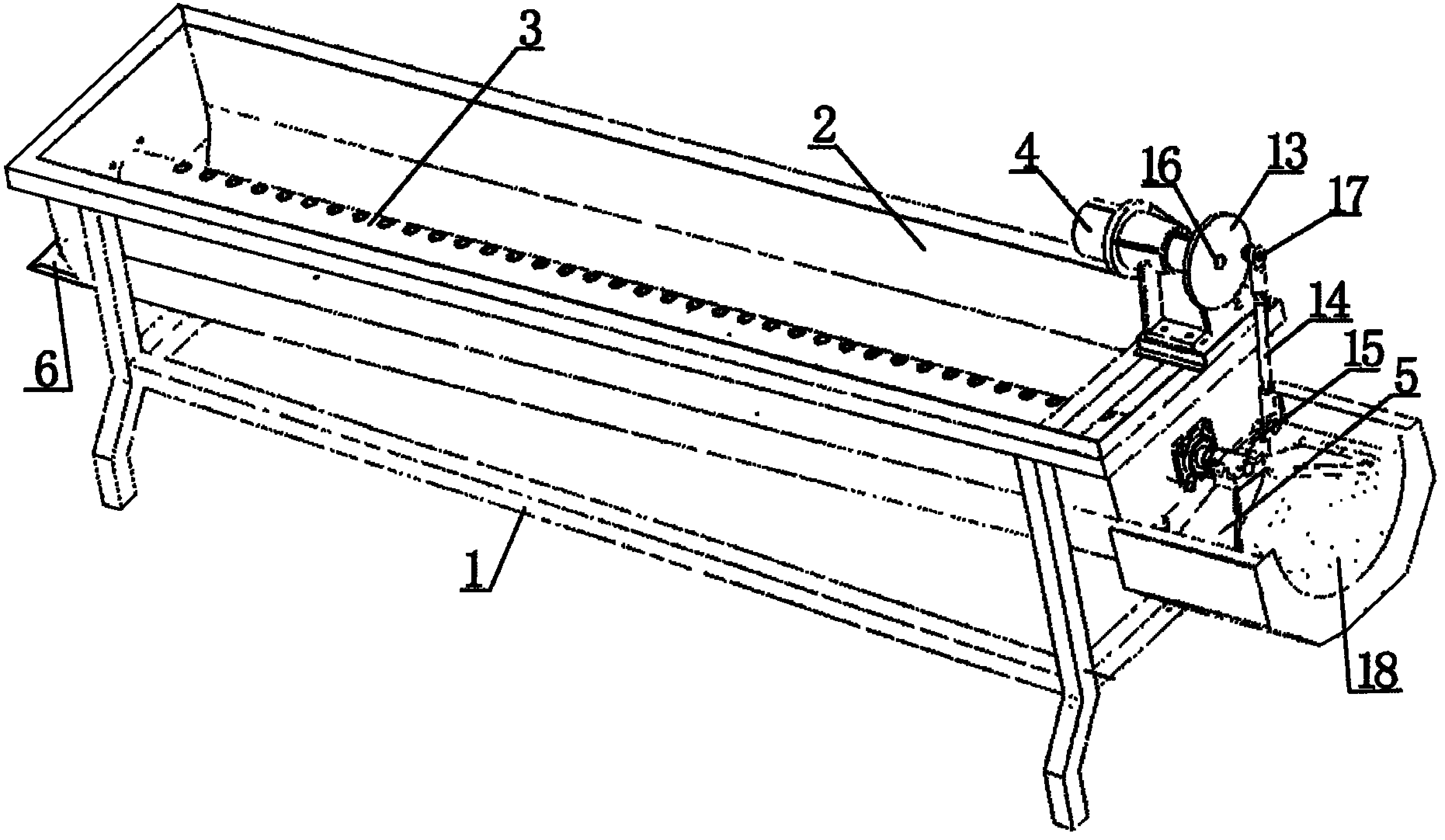

[0013] Such as figure 1 , 2 As shown, the automatic shelling machine for shrimp products is composed of a frame 1, a shell grinding tank 2, a grinding wheel device, a transmission mechanism and a motor 4. The frame 1 is a rectangular parallelepiped frame structure with one end high and the other end low. Groove 2 is arranged on the frame 1, and its one end is provided with feed inlet 5, and the other end is provided with discharge outlet 6, and its groove bottom surface is arc-shaped surface; 7, the roller shaft 3 is arranged in the grinding shell groove 2, and the plurality of telescopic frames 8 are arranged on the roller shaft 3, and are arranged side by side along the axial direction of the roller shaft; the telescopic frame 8 is formed by a fixed frame 9 and return spring 10 and two guide rods 11, one end of the two guide rods 11 is inserted in the corresponding through hole 12 on the surface of the roller 3, the other end is connected with the fixed frame 9, and the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com