Enhanced flat cable

A flat cable and reinforced technology, applied in the field of reinforced flat cables, can solve the problems of shortening the service life of the cable, damage to the circuit, etc., and achieve the effect of increasing the strength and the bending performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

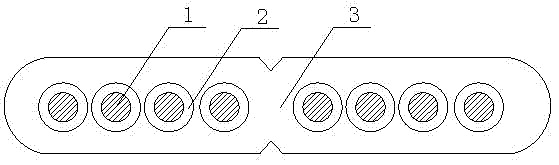

[0010] The reinforced flat cable of the present invention is basically composed of a wire core. The wire core is composed of a twisted wire 1 in the middle and an insulating layer 2 extruded outside the twisted wire. Several wire cores are arranged in parallel to form a cable core. A flat sheath 3 is formed outside.

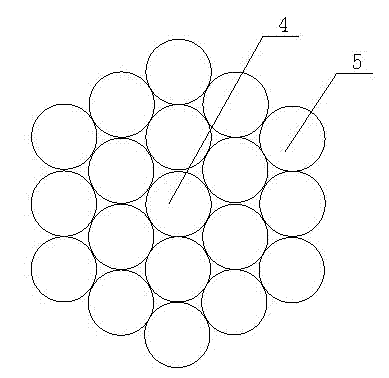

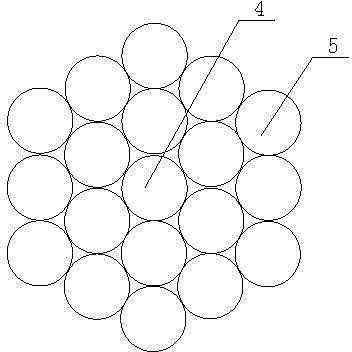

[0011] The twisted wires of this type of cable are all composed of the fifth type of conductor bundles in the national standard GB3956-2008, while the twisted wires of the present invention add a reinforcing core of the same specification to the center of several twisted wires of copper wires 5 4. Without affecting the electrical conductivity, the strength of the cable core is greatly increased, and the bending performance is greatly increased. like figure 2 , For example, the core of an elevator cable includes 8 core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com