Sound absorption plate

A sound-absorbing panel and panel body technology, applied in the direction of sound insulation, building components, layered products, etc., can solve the problems of being unsuitable for large-scale promotion, cumbersome assembly process, and poor practicability, and achieve light weight, simple structure, and absorption good sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

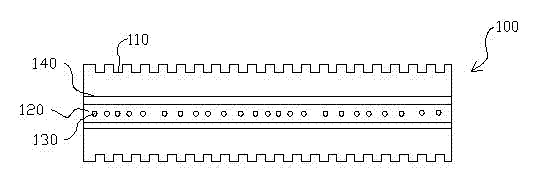

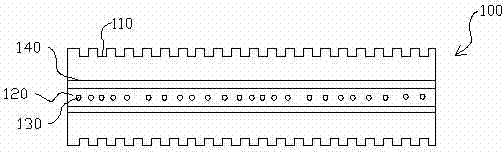

[0013] Such as figure 1 As shown, a sound-absorbing panel according to the present invention includes a board body 100, the board body 100 is essential, the upper layer and the lower layer of the board body 100 are respectively provided with grooves 110, and in the middle of the board body 100 A foamed polystyrene layer 120 is provided, and a mortar layer 140 is provided on one side of the foamed polystyrene layer 120 . In one embodiment of the present invention, the grooves 110 are evenly distributed on the upper layer and the lower layer of the plate body, and the sizes of the grooves 110 are the same. The shape of the block 100 is a square with a length of 1200 mm and a width of 1200 mm. In addition, the foamed polystyrene layer 120 is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com